Toyota Venza: Mass Air Flow Meter

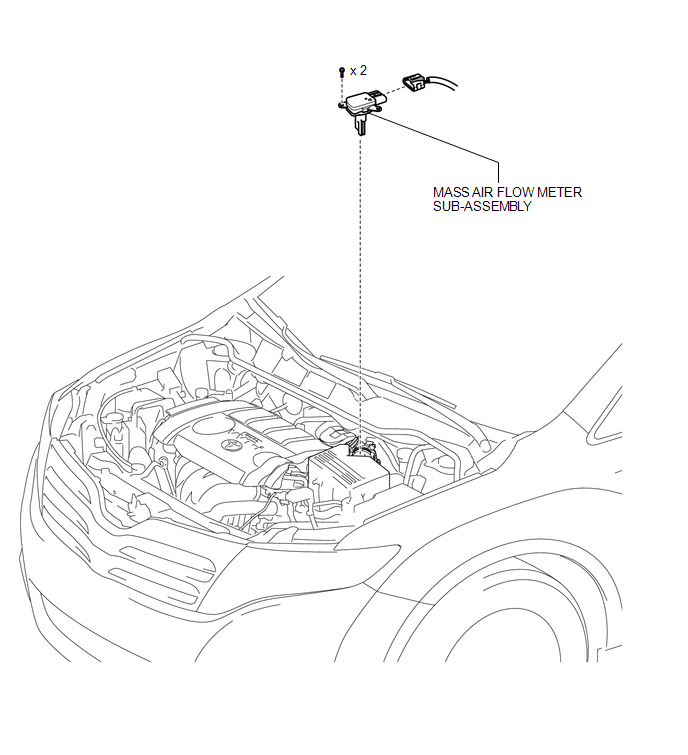

Components

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

NOTICE:

- Perform the mass air flow meter inspection according to the procedure below.

- Only replace the mass air flow meter when the mass air flow value in the Data List (with the engine stopped) is not within the normal operating range or there is foreign matter on the mass air flow meter platinum hot wire (heater).

HINT:

Perform "Inspection After Repairs" after replacing the mass air flow meter (See

page .gif) ).

).

PROCEDURE

1. INSPECT MASS AIR FLOW METER SUB-ASSEMBLY

NOTICE:

- Perform the inspection with the vehicle indoors and on a level surface.

- Perform the inspection of the mass air flow meter while it is installed to the air cleaner case (installed to the vehicle).

- During the test, do not use the exhaust air duct to perform suction on the exhaust pipe.

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON (do not run the engine).

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Data List / MAF.

(e) Wait 30 seconds, and read the values on the Techstream.

Standard:

|

Item |

Condition |

Specified Condition |

|---|---|---|

|

MAF |

|

Less than 0.5 g/sec. |

If the result is not as specified, replace the mass air flow meter sub-assembly.

If the result is as specified, inspect the mass air flow meter sub-assembly (See

page .gif) ).

).

Removal

REMOVAL

PROCEDURE

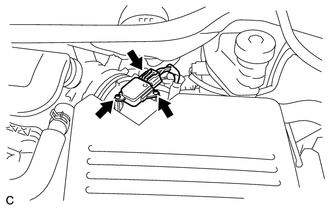

1. REMOVE MASS AIR FLOW METER SUB-ASSEMBLY

|

(a) Disconnect the mass air flow meter connector. |

|

(b) Remove the 2 screws and mass air flow meter.

Inspection

INSPECTION

PROCEDURE

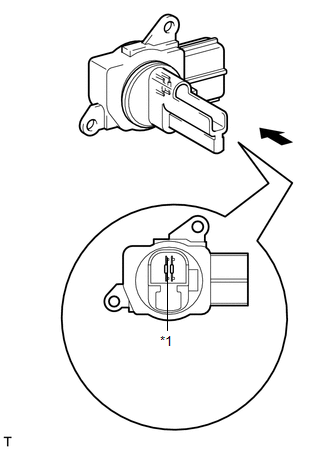

1. INSPECT MASS AIR FLOW METER SUB-ASSEMBLY

|

(a) Perform a visual check for any foreign matter on the platinum hot wire (heater) of the mass air flow meter shown in the illustration. Text in Illustration

OK: There is no foreign material. |

|

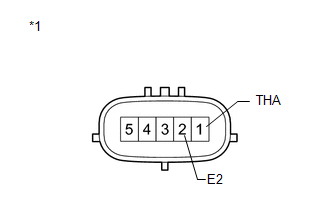

(b) Check the intake air temperature sensor (built into the mass air flow meter).

|

(1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the mass air flow meter sub-assembly. Text in Illustration

|

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL MASS AIR FLOW METER SUB-ASSEMBLY

|

(a) Install the mass air flow meter with the 2 screws. NOTICE: Make sure that the O-ring is not cracked or jammed when installing the mass air flow meter. HINT: Perform "Inspection After Repair" after replacing the mass air flow meter

sub-assembly (See page |

|

(b) Connect the mass air flow meter connector.

Knock Sensor

Knock Sensor

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE INTAKE MANIFOLD

(a) Remove the intake manifold (See page ).

2. REMOVE KNOCK SENSOR

(a) Disconnect the ...

Relay

Relay

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT IG2 RELAY

(a) Remove the IG2 relay from the relay block.

(b) Measure the resistance according to the value(s) in the ...

Other materials about Toyota Venza:

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) Air conditioning system data and the Diagnostic Trouble Codes (DTCs) can

be read through the Data Link Connector 3 (DLC3) of the vehicle. When the system

seems to be malfunctioning, use the Techstream to check for malf ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL GENERATOR ROTOR ASSEMBLY

(a) Place the generator drive end frame on the generator pulley.

(b) Install the generator rotor to the generator drive end frame.

...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL NO. 2 STEERING RACK BOOT

(a) Apply lithium soap base glycol grease to the inside of the small

opening of a new No. 2 steering rack boot.

(b) Install the No. 2 ste ...

0.1522

.gif) ).

)..png)