Toyota Venza: On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. SEPARATE FRONT DISC BRAKE CALIPER ASSEMBLY

.gif)

3. REMOVE FRONT DISC

.gif)

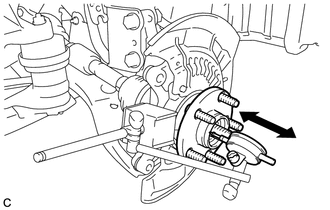

4. INSPECT FRONT AXLE HUB BEARING LOOSENESS

|

(a) Using a dial indicator, check for looseness near the center of the front axle hub. Maximum looseness: 0.05 mm (0.00196 in.) NOTICE: Ensure that the dial indicator is set perpendicular to the measurement surface. If the looseness exceeds the maximum, replace the front axle hub bearing. |

|

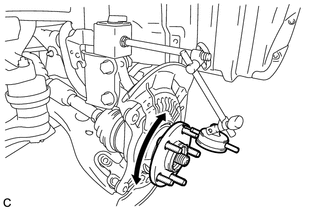

5. INSPECT FRONT AXLE HUB RUNOUT

|

(a) Using a dial indicator, check for runout on the surface of the axle hub outside the hub bolt. Maximum runout: 0.05 mm (0.00196 in.) NOTICE: Ensure that the dial indicator is set perpendicular to the measurement surface. If the runout exceeds the maximum, replace the front axle hub sub-assembly. |

|

6. INSTALL FRONT DISC

.gif)

7. INSTALL FRONT DISC BRAKE CALIPER ASSEMBLY

.gif)

8. INSTALL FRONT WHEEL

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. REMO ...

Other materials about Toyota Venza:

Checking Monitor Status

CHECKING MONITOR STATUS

The purpose of the monitor result (mode 06) is to allow access to the results

of on-board diagnostic monitoring tests of specific components/systems that are

not continuously monitored. Examples are catalysts and evaporative emissi ...

Follow the correction procedures. (smart key system)

After taking the specified steps to correct the suspected problem, check that

the warning light turns off.

- If the malfunction indicator lamp comes on while driving

First check the following:

• Is the fuel empty?

If it is, fill the fuel tan ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT SUSPENSION MEMBER BODY MOUNTING REAR CUSHION LH

(a) Temporarily install a new front suspension member body mounting rear

cushion LH while confirming the installation direction.

NOTICE:

Position th ...

0.1204