Toyota Venza: Parking Brake Switch Circuit

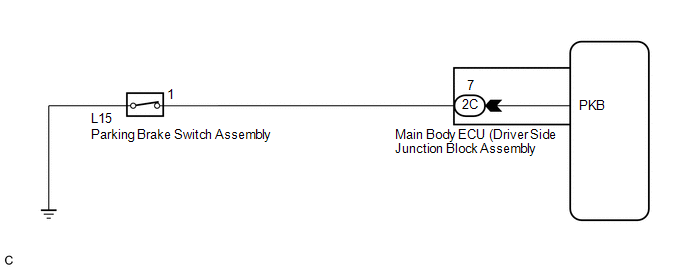

DESCRIPTION

The main body ECU (driver side junction block assembly) detects the condition of the parking brake switch.

WIRING DIAGRAM

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Data List.

(e) Read the display on the Techstream.

Main Body|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Parking Brake SW |

Parking brake SW signal/ON or OFF |

ON: Parking brake switch on OFF: Parking brake switch off |

- |

OK:

Normal conditions listed above are displayed.

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

INSPECT PARKING BRAKE SWITCH ASSEMBLY |

|

(a) Remove the parking brake switch assembly (See page

|

|

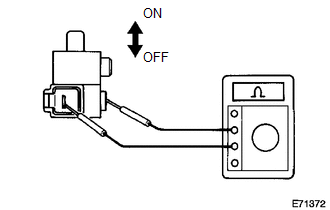

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - Switch body |

Shaft pushed in (OFF) |

10 kΩ or higher |

|

1 - Switch body |

Shaft not pushed in (ON) |

Below 1 Ω |

| NG | .gif) |

REPLACE PARKING BRAKE SWITCH ASSEMBLY |

|

|

3. |

CHECK HARNESS AND CONNECTOR (SWITCH - MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY)) |

|

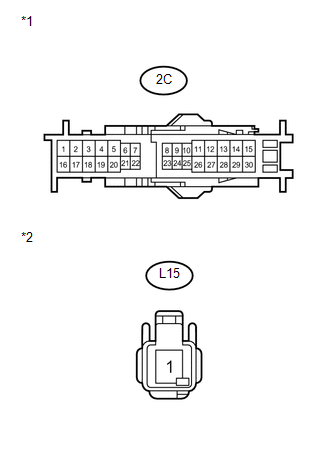

(a) Disconnect the 2C main body ECU (driver side junction block assembly) connector. |

|

(b) Disconnect the L15 parking brake switch assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2C-7 - L15-1 |

Always |

Below 1 Ω |

|

2C-7 - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector: (to Main Body ECU (Driver Side Junction Block Assembly)) |

|

*2 |

Front view of wire harness connector (to Parking Brake Switch Assembly) |

| OK | .gif) |

REPLACE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Door Mirror Foot Light Circuit

Door Mirror Foot Light Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) controls the door mirror

foot lights.

WIRING DIAGRAM

1. w/o Seat Position Memory:

2. w/ Seat Position Memory:

PROCEDURE

...

Taillight Relay Circuit

Taillight Relay Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) controls the operation

of the TAIL relay.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits rel ...

Other materials about Toyota Venza:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

ECM / PCM Internal Engine Off Timer Performance (P2610)

DTC SUMMARY

DTC No.

Monitoring Item

Malfunction Detection Condition

Trouble Area

Detection Timing

Detection Logic

P2610

Soak timer (built into ECM)

An ECM ...

Back Door Entry Lock and Unlock Functions do not Operate

DESCRIPTION

When the back door entry lock and unlock functions do not operate, one of the

following may be malfunctioning: 1) power door lock control system; 2) outside electrical

key oscillator (for rear side); 3) certification ECU (smart key ECU assembl ...

0.115

.gif)

.gif) ).

).