Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT EVAPORATOR TEMPERATURE SENSOR

(a) Measure the resistance according to the value(s) in the table below.

.png)

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

-10°C (14°F) |

7.30 to 9.10 kΩ |

|

1 - 2 |

-5°C (23°F) |

5.65 to 6.95 kΩ |

|

1 - 2 |

0°C (32°F) |

4.40 to 5.35 kΩ |

|

1 - 2 |

5°C (41°F) |

3.40 to 4.15 kΩ |

|

1 - 2 |

10°C (50°F) |

2.70 to 3.25 kΩ |

|

1 - 2 |

15°C (59°F) |

2.14 to 2.58 kΩ |

|

1 - 2 |

20°C (68°F) |

1.71 to 2.05 kΩ |

|

1 - 2 |

25°C (77°F) |

1.38 to 1.64 kΩ |

|

1 - 2 |

30°C (86°F) |

1.11 to 1.32 kΩ |

NOTICE:

- Hold the sensor only by its connector. Touching the sensor may change the resistance value.

- When measuring, the sensor temperature must be the same as the ambient temperature.

HINT:

As the temperature increases, the resistance decreases (see the graph).

If the resistance is not as specified, replace the evaporator temperature sensor.

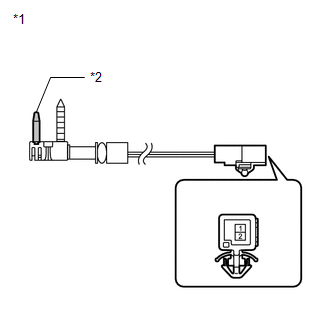

Text in Illustration|

*1 |

Component without harness connected (Evaporator Temperature Sensor) |

|

*2 |

Sensing Portion |

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE AIR CONDITIONING UNIT ASSEMBLY

(See page )

2. REMOVE NO. 1 FINISH PANEL MOUNTING BRACKET

3. REMOVE NO. 2 FINISH PANEL MOUNTING BRACKET

4. REMOVE NO. 3 AIR DUCT ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 1 COOLER THERMISTOR

(a) Install the No. 1 cooler thermistor as shown in the illustration.

Part

Length

...

Other materials about Toyota Venza:

Vehicle Speed Sensor "A" (P0500)

DESCRIPTION

The speed sensors detect the wheel speed and send the appropriate signals to

the skid control ECU. The skid control ECU converts these wheel speed signals into

a 4-pulse signal and outputs it to the TCM via the combination meter. The TCM deter ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT SHIFT SOLENOID VALVE SL

(a) Measure the resistance according to the value(s) in the table below.

Text in Illustration

*1

Shift Solenoid Valve SL

Standard Re ...

Drive Shaft System

Precaution

PRECAUTION

1. NOTICE OF REMOVING AND INSTALLING FRONT DRIVE SHAFT ASSEMBLY RH

(a) When removing and installing the front drive shaft assembly RH in a AWD vehicle,

be sure to first drain all the transaxle oil and transfer oil. If removal and i ...

0.1296