Toyota Venza: Illumination Circuit

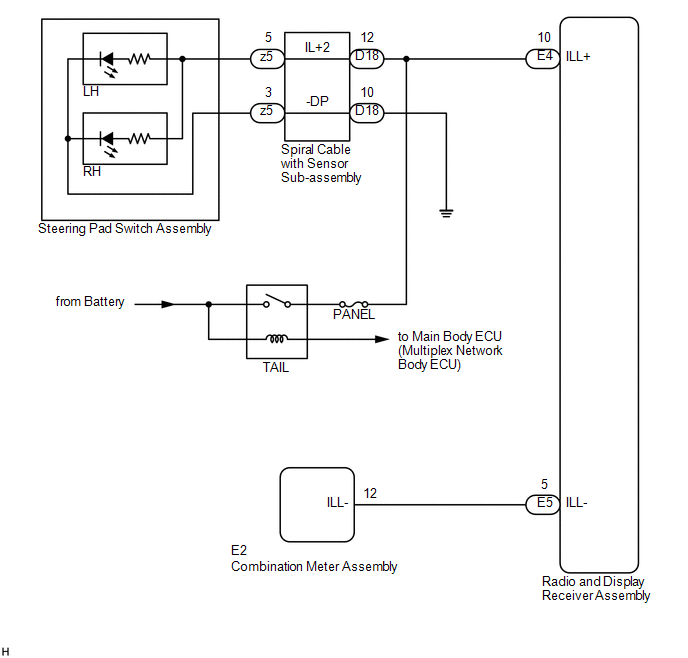

DESCRIPTION

Power is supplied to the radio and display receiver assembly and steering pad switch assembly illumination when the light control switch is in the tail or head position.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- The vehicle is equipped with a Supplemental Restraint System (SRS) which

includes components such as airbags. Before servicing (including removal

or installation of parts), be sure to read the precaution for Supplemental

Restraint System (See page

.gif) ).

). - Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK ILLUMINATION |

(a) Check if the illumination for the radio and display receiver assembly, steering pad switch assembly, heater control switch or others (hazard switch, transmission control switch, etc.) comes on when the light control switch is turned to the head or tail position.

|

Result |

Proceed to |

|---|---|

|

Illumination comes on for all components except steering pad switch assembly. |

A |

|

Illumination comes on for all components except radio and display receiver assembly. |

B |

|

Illumination comes on only for steering pad switch assembly. |

C |

|

No illumination comes on (radio and display receiver assembly, hazard switch, heater control switch, etc.). |

D |

| B | .gif) |

GO TO STEP 5 |

| C | .gif) |

GO TO METER / GAUGE SYSTEM |

| D | .gif) |

GO TO LIGHTING SYSTEM |

|

|

2. |

CHECK HARNESS AND CONNECTOR (ILLUMINATION SIGNAL) |

(a) Disconnect the D18 spiral cable with sensor sub-assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D18-12 (IL+2) - Body ground |

Light control switch in the tail or head position |

11 to 14 V |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

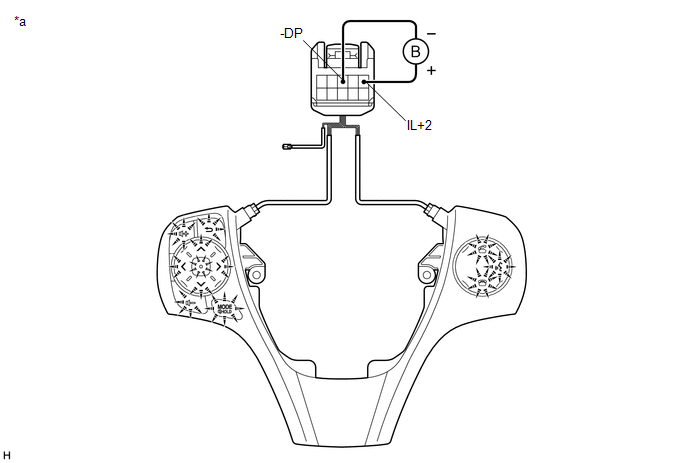

INSPECT STEERING PAD SWITCH ASSEMBLY |

(a) Remove the steering pad switch assembly (See page

.gif) ).

).

(b) Connect a battery positive (+) lead to terminal 5 (IL+2) and a negative (-) lead to terminal 3 (-DP) of the steering pad switch assembly connector.

Text in Illustration

Text in Illustration

|

*a |

Component without harness connected (Steering Pad Switch Assembly) |

- |

- |

(c) Check if the illumination for the steering pad switch assembly comes on.

OK:

Illumination for the steering pad switch assembly comes on.

| NG | .gif) |

REPLACE STEERING PAD SWITCH ASSEMBLY |

|

|

4. |

INSPECT SPIRAL CABLE WITH SENSOR SUB-ASSEMBLY |

(a) Remove the spiral cable with sensor sub-assembly (See page

.gif) ).

).

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(c) After setting the spiral cable with sensor sub-assembly to the center position, rotate the spiral cable with sensor sub-assembly 2.5 times clockwise. Then while rotating the spiral cable with sensor sub-assembly 5 times counterclockwise, measure the resistance according to the value(s) the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

z5-5 (IL+2) - D18-12 (IL+2) |

Always |

3 Ω or less |

|

z5-3 (-DP) - D18-10 (-DP) |

Always |

3 Ω or less |

NOTICE:

- The spiral cable with sensor sub-assembly is an important part of the SRS airbag system. Incorrect removal or installation of the spiral cable with sensor sub-assembly may prevent the airbag from deploying.

- As the spiral cable with sensor sub-assembly may break, do not rotate the spiral cable with sensor sub-assembly more than the specified amount.

|

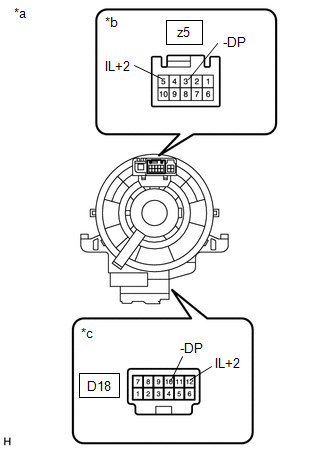

*a |

Component without harness connected (Spiral Cable with Sensor Sub-assembly) |

|

*b |

Steering Pad Switch Assembly Side |

|

*c |

Vehicle Side |

| OK | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (SPIRAL CABLE WITH SENSOR SUB-ASSEMBLY - BODY GROUND) |

| NG | .gif) |

REPLACE SPIRAL CABLE WITH SENSOR SUB-ASSEMBLY |

|

5. |

CHECK HARNESS AND CONNECTOR (ILLUMINATION SIGNAL) |

(a) Disconnect the E4 radio and display receiver assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E4-10 (ILL+) - Body ground |

Light control switch in the tail or head position |

11 to 14 V |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. |

CHECK HARNESS AND CONNECTOR (RADIO AND DISPLAY RECEIVER ASSEMBLY - COMBINATION METER ASSEMBLY) |

(a) Disconnect the E5 radio and display receiver assembly connector.

(b) Disconnect the E2 combination meter assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E5-5 (ILL-) - E2-12 (ILL-) |

Always |

Below 1 Ω |

|

E5-5 (ILL-) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Steering Pad Switch Circuit

Steering Pad Switch Circuit

DESCRIPTION

This circuit sends an operation signal from the steering pad switch assembly

to the radio and display receiver assembly.

If there is an open in the circuit, the audio system cannot be ...

Parking Brake Switch Circuit

Parking Brake Switch Circuit

DESCRIPTION

This circuit is from the parking brake switch assembly to the radio and display

receiver assembly.

WIRING DIAGRAM

PROCEDURE

1.

CHECK BRAKE WARNING LIGHT

...

Other materials about Toyota Venza:

Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. DRAIN DIFFERENTIAL OIL

2. REMOVE REAR WHEEL

3. REMOVE CENTER EXHAUST PIPE ASSE ...

Open in Rear Floor Electrical Key Oscillator Circuit (B27A6)

DESCRIPTION

The certification ECU (smart key ECU assembly) generates a request signal and

sends it to the indoor electrical key oscillator (for center floor). To detect the

key inside the cabin, the indoor electrical key oscillator (for center floor) crea ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL NO. 14 ROOF SILENCER PAD

(a) Align the markings on the roof headlining assembly with the No. 14 roof silencer

pad and install the silencer pad using hot-melt glue as shown in the illustration.

2. INSTALL NO. 1 ROOF WIRE ...

0.1305

.gif)