Toyota Venza: Taillight Relay Circuit

DESCRIPTION

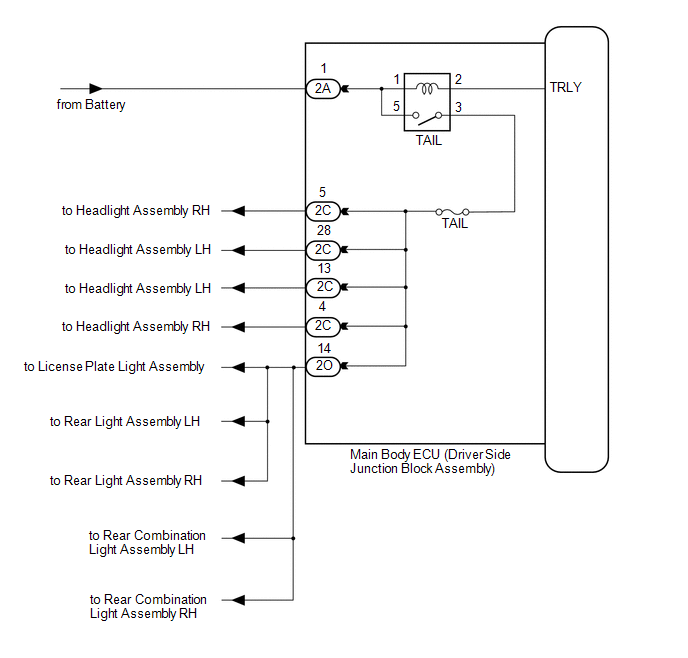

The main body ECU (driver side junction block assembly) controls the operation of the TAIL relay.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Active Test.

(e) Check that the relay operates.

Main Body|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Taillight Relay |

Taillight relay |

ON/OFF |

- |

OK:

Taillight relay operates. (Taillights illuminate.)

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

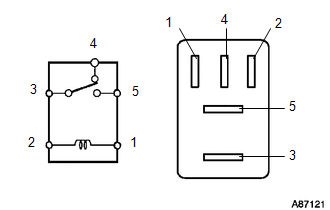

INSPECT TAILLIGHT RELAY (TAIL) |

|

(a) Remove the taillight relay from the main body ECU (driver side junction block assembly). |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3 - 5 |

Voltage is not applied between terminals 1 and 2 |

10 kΩ or higher |

|

Apply the battery voltage between terminals 1 and 2 |

Below 1 Ω |

|

|

3 - 4 |

Voltage is not applied between terminals 1 and 2 |

Below 1 Ω |

|

Apply the battery voltage between terminals 1 and 2 |

10 kΩ or higher |

| NG | .gif) |

REPLACE TAILLIGHT RELAY |

|

|

3. |

CHECK HARNESS AND CONNECTOR (BATTERY - MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

|

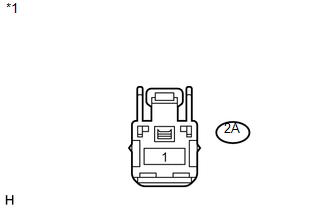

(a) Disconnect the 2A main body ECU (driver side junction block assembly) connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2A-1 - Body ground |

Always |

11 to 14 V |

|

*1 |

Front view of wire harness connector (to Main Body ECU (Driver Side Junction Block Assembly)) |

| OK | .gif) |

REPLACE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Parking Brake Switch Circuit

Parking Brake Switch Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) detects the condition

of the parking brake switch.

WIRING DIAGRAM

PROCEDURE

1.

READ VALUE USING TECHS ...

Headlight Beam Level Control Actuator Circuit

Headlight Beam Level Control Actuator Circuit

DESCRIPTION

The headlight leveling ECU assembly actuates the headlight leveling motor according

to vehicle conditions.

WIRING DIAGRAM

PROCEDURE

1.

READ VALUE USING TECHS ...

Other materials about Toyota Venza:

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

NOTICE:

After replacing the stereo component tuner assembly of vehicles subscribed to

pay-type satellite radio broadcasts, XM radio ID registration is necessary (w/ SDARS

System).

HINT:

Use the table below to help determi ...

Dtc Check / Clear

DTC CHECK / CLEAR

NOTICE:

When the diagnosis system is changed from normal mode to check mode or vice versa,

all DTCs and freeze frame data recorded in normal mode are cleared. Before changing

modes, always check and make a note of DTCs and freeze frame ...

Ambient Temperature Sensor

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT AMBIENT TEMPERATURE SENSOR

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

C ...

0.1362

.gif)