Toyota Venza: Low Power Supply Voltage (C1241/94)

DESCRIPTION

If a malfunction in the power source circuit occurs, or a malfunction in communication with the skid control ECU or in a speed sensor occurs, the AWD control ECU will prohibit operations by the fail-safe function.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

C1241/94 |

|

|

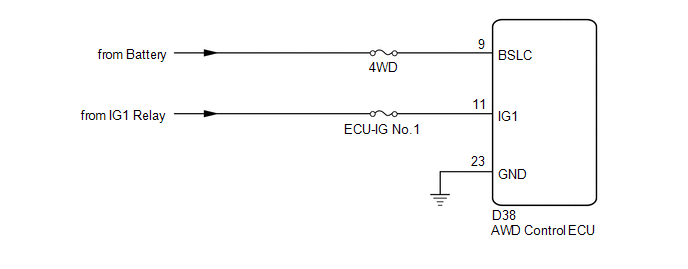

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

HINT:

Check the condition of each related circuit connector before troubleshooting

(See page .gif) ).

).

PROCEDURE

|

1. |

CHECK FOR DTC (CAN COMMUNICATION SYSTEM AND BRAKE CONTROL SYSTEM) |

(a) Check if the CAN communication system DTC is output (See page

.gif) ).

).

(b) Start the engine.

(c) Drive the vehicle, accelerate to a speed of 3 km/h (2 mph) or more, and check

if the speed sensor DTC (brake control system DTC) is output (See page

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

Neither CAN communication system DTC nor speed sensor DTC (brake control system DTC) is output |

A |

|

CAN communication system DTC is output |

B |

|

Speed sensor DTC (brake control system DTC) is output |

C |

| B | .gif) |

REPAIR CIRCUIT INDICATOR BY OUTPUT CODE (CAN COMMUNICATION SYSTEM) |

| C | .gif) |

REPAIR CIRCUIT INDICATOR BY OUTPUT CODE (BRAKE CONTROL SYSTEM) |

|

|

2. |

INSPECT BATTERY |

(a) Check the battery voltage.

Standard Voltage:

11 to 14 V

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (2GR-FE) |

B |

|

NG (1AR-FE) |

C |

| B | .gif) |

INSPECT CHARGING SYSTEM (2GR-FE) |

| C | .gif) |

INSPECT CHARGING SYSTEM (1AR-FE) |

|

|

3. |

CHECK WIRE HARNESS (AWD CONTROL ECU - BATTERY) |

(a) Disconnect the ECU connector.

(b) Measure the voltage of the wire harness side connector.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

D38-11 (IG1) - Body Ground |

Ignition switch ON |

11 to 14 V |

|

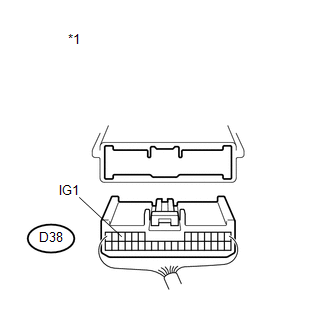

*1 |

Rear view of wire harness connector (to AWD Control ECU) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK WIRE HARNESS (AWD CONTROL ECU - BODY GROUND) |

(a) Disconnect the ECU connector.

(b) Measure the resistance of the wire harness side connector.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D38-23 (GND) - Body Ground |

Always |

Below 1 Ω |

|

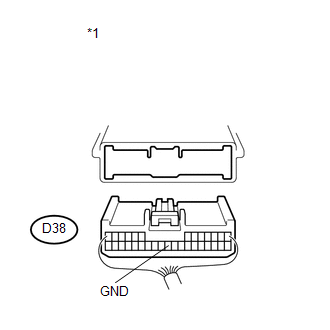

*1 |

Rear view of wire harness connector (to AWD Control ECU) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

RECONFIRM DTC |

(a) Clear the DTC (See page .gif) ).

).

(b) Start the engine.

(c) Drive the vehicle, accelerate to a speed of 3 km/h (2 mph or more, and check if the same DTC is output.

|

Result |

Proceed to |

|---|---|

|

DTC is output |

A |

|

DTC is not output |

B |

HINT:

Reinstall the sensor, connectors, etc. and restore the vehicle to its prior condition before rechecking DTCs.

| A | .gif) |

REPLACE AWD CONTROL ECU |

| B | .gif) |

CHECK INTERMITTENT PROBLEMS |

Diagnostic Trouble Code Chart

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

ACTIVE TORQUE CONTROL 4WD SYSTEM

DTC Code

Detection Item

Trouble Area

See page

C1241/94

Low Powe ...

Control Module Communication Bus OFF (U0073/86,U0100/85,U0129/83)

Control Module Communication Bus OFF (U0073/86,U0100/85,U0129/83)

DESCRIPTION

The AWD control ECU inputs the signals sent from the ECM and skid control

ECU via the CAN communication system.

When DTCs indicating a CAN communication system malfunction ...

Other materials about Toyota Venza:

Inspection

INSPECTION

PROCEDURE

1. INSPECT BRAKE VACUUM CHECK VALVE ASSEMBLY

(a) Check that there is ventilation from the booster to the engine, and

no ventilation from the engine to the booster.

If the results are not as specified, replace the brake ...

Floor mats

Use only floor mats designed specifically for vehicles of the same model and

model year as your vehicle. Fix them securely in place onto the carpet.

Insert the retaining hooks (clips) into the floor mat eyelets.

Turn the upper knob of each retaining ho ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

0.1151

.gif)