Toyota Venza: On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. SEPARATE REAR FLEXIBLE HOSE

.gif)

3. SEPARATE REAR DISC BRAKE CALIPER ASSEMBLY

.gif)

4. REMOVE REAR DISC

.gif)

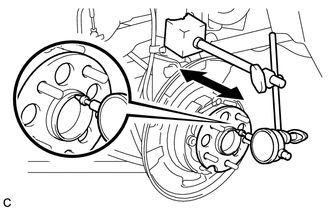

5. INSPECT REAR AXLE HUB BEARING LOOSENESS

|

(a) Using a dial indicator, check for looseness near the center of the axle hub. Maximum looseness: 0.05 mm (0.00196 in.) NOTICE: Ensure that the dial indicator is set perpendicular to the measurement surface. If the looseness exceeds the maximum, replace the rear axle hub and bearing assembly. |

|

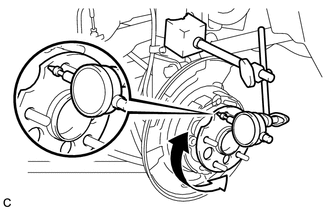

6. INSPECT REAR AXLE HUB RUNOUT

|

(a) Using a dial indicator, check for runout on the surface of the axle hub outside the hub bolt. Maximum runout: 0.08 mm (0.00314 in.) NOTICE: Ensure that the dial indicator is set perpendicular to the measurement surface. If the runout exceeds the maximum, replace the rear axle hub and bearing assembly. |

|

7. INSTALL REAR DISC

.gif)

8. INSTALL REAR DISC BRAKE CALIPER ASSEMBLY

.gif)

9. INSTALL REAR FLEXIBLE HOSE

.gif)

10. INSTALL REAR WHEEL

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

Components

Components

COMPONENTS

ILLUSTRATION

...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. SEPAR ...

Other materials about Toyota Venza:

Power Window Motor Malfunction (B2311)

DESCRIPTION

The power window regulator motor is operated by the power window regulator master

switch assembly or power window regulator switch assembly. The power window regulator

motor assembly has motor, regulator and ECU functions.

This DTC is output ...

Starting System

Parts Location

PARTS LOCATION

ILLUSTRATION

ILLUSTRATION

System Diagram

SYSTEM DIAGRAM

...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL NO. 2 STEERING RACK BOOT

(a) Apply lithium soap base glycol grease to the inside of the small

opening of a new No. 2 steering rack boot.

(b) Install the No. 2 ste ...

0.1626