Toyota Venza: Monitor Drive Pattern

MONITOR DRIVE PATTERN

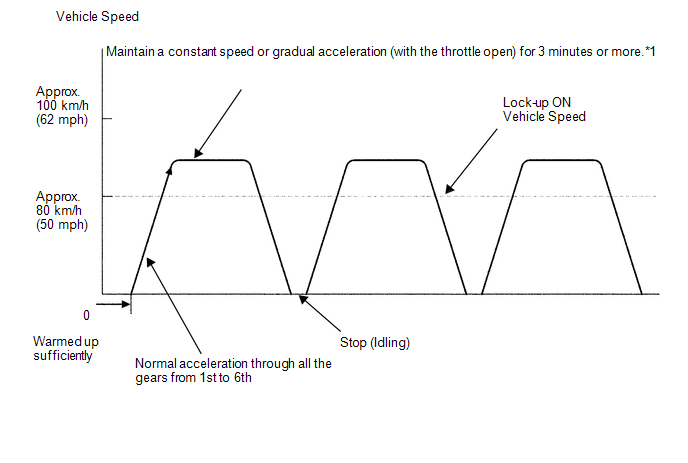

1. TEST MONITOR DRIVE PATTERN FOR ECT

CAUTION:

Perform this drive pattern on a level surface and strictly observe the posted speed limits and traffic laws while driving.

HINT:

Performing this drive pattern is one method to simulate the TCM (ECT) malfunction detection conditions.

Some DTCs may not be detected through ordinary, everyday driving. Also, DTCs may not be detected through this drive pattern.

(a) Preparation for driving

(1) Warm up the engine sufficiently (engine coolant temperature is 60°C (140°F) or higher).

(2) Drive the vehicle when the atmospheric temperature is -10°C (14°F) or higher.

Some malfunctions are not detected when the atmospheric temperature is less than -10°C (14°F).

(b) Drive pattern

(1) Drive the vehicle through all the gears.

Stop → 1st → 2nd → 3rd → 4th → 5th → 6th → 6th (lock-up ON).

(2) Confirm engine braking using the S position. While driving with S6 range selected and 6th gear operating with lock-up on, move the shift lever toward "-" to downshift from 6 to 5, 5 to 4, 4 to 3, 3 to 2, 2 to 1.

(3) Repeat the above drive pattern three times or more.

NOTICE:

- When using the Techstream, the monitor status can be checked in the

Data List (See page

.gif) ).

). - In the event that the drive pattern must be interrupted (due to traffic conditions or other factors), the drive pattern can be resumed and, in most cases, the monitor can be completed.

HINT:

*1: Drive the vehicle at a speed in top gear that will cause lock-up to engage. The vehicle can be driven at a speed lower than that in the above diagram under the lock-up condition.

NOTICE:

It is necessary to drive the vehicle for approximately 30 minutes to detect DTC P0711 (ATF temperature sensor malfunction).

Initialization

Initialization

INITIALIZATION

1. RESET TRANSAXLE COMPENSATION CODE

NOTICE:

If the following parts have been replaced, initialize the TCM and perform

the following "Reset Memory" and "Pe ...

Problem Symptoms Table

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are lis ...

Other materials about Toyota Venza:

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK RADIATOR CAP SUB-ASSEMBLY

(a) Measure the valve opening pressure.

(1) If there are water stains or foreign matter on rubber packings 1, 2 or 3,

clean the part(s) with water and finger scouring.

(2) Check that r ...

Removal

REMOVAL

PROCEDURE

1. REMOVE PARKING BRAKE PEDAL ASSEMBLY

HINT:

Refer to the instructions for Removal of the parking brake pedal assembly (See

page ).

2. REMOVE NO. 1 PARKING BRAKE CABLE ASSEMBLY

(a) Remove the clip.

...

Inspection

INSPECTION

PROCEDURE

1. INSPECT POWER WINDOW REGULATOR SWITCH ASSEMBLY (for Rear LH)

(a) Check the switch function.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Co ...

0.1226