Toyota Venza: Removal

REMOVAL

PROCEDURE

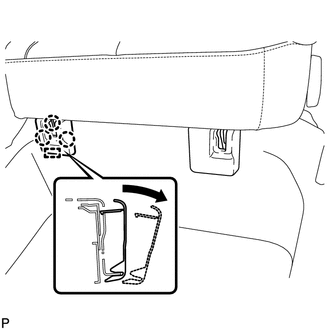

1. REMOVE REAR SEAT HEADREST ASSEMBLY

|

(a) Press the headrest support button and pull up the headrest as shown in the illustration to remove it. |

|

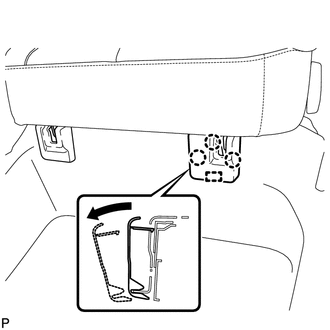

2. REMOVE REAR SEAT INNER TRACK BRACKET COVER

|

(a) Disengage the 3 claws and guide, and remove the rear seat inner track bracket cover as shown in the illustration. |

|

3. REMOVE REAR SEAT OUTER TRACK BRACKET COVER

|

(a) Disengage the 3 claws and guide, and remove the rear seat outer track bracket cover as shown in the illustration. |

|

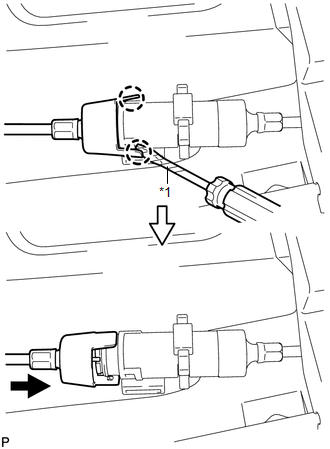

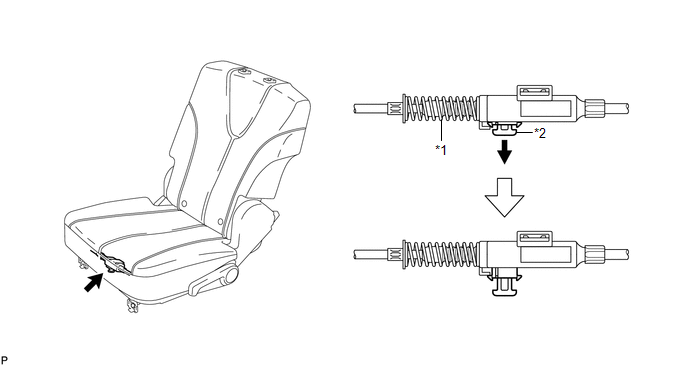

4. DISCONNECT REAR SEAT NO. 2 RECLINING CONTROL CABLE SUB-ASSEMBLY

(a) Pull down the adjuster's lock piece to release the lock as shown in the illustration.

Text in Illustration

Text in Illustration

|

*1 |

Adjuster Spring |

*2 |

Lock Piece |

|

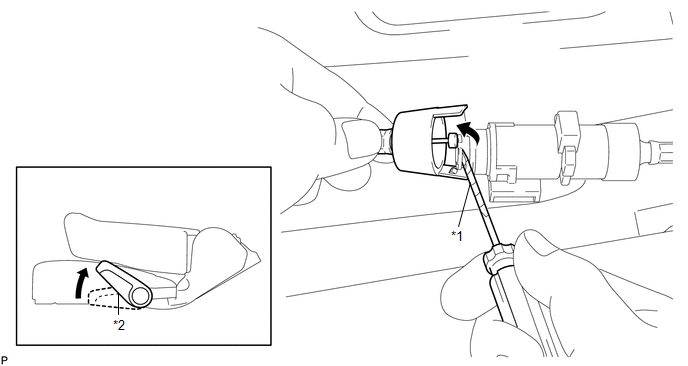

(b) Using a screwdriver wrapped with protective tape, disengage the 2 claws as shown in the illustration. Text in Illustration

|

|

(c) Lift up the seat track adjusting handle to the uppermost position and hold the handle in this position as shown in the illustration.

Text in Illustration

Text in Illustration

|

*1 |

Seat Track Adjusting Handle |

*2 |

Protective Tap |

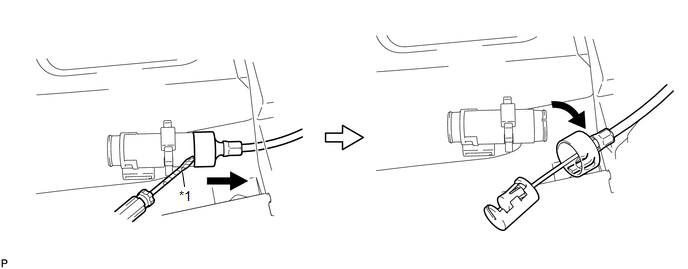

(d) Using a screwdriver wrapped with protective tape, disconnect the rear seat reclining control cable sub-assembly as shown in the illustration.

Text in Illustration

Text in Illustration

|

*1 |

Protective Tape |

(e) Secure the rear seat No. 2 reclining control cable sub-assembly with the carpet hole as shown in the illustration.

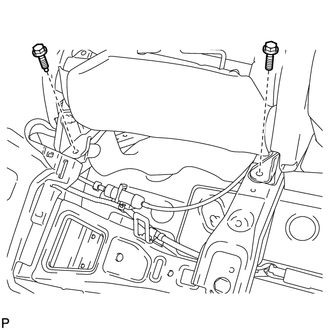

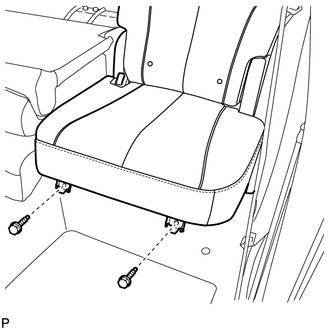

5. REMOVE REAR SEAT ASSEMBLY LH

|

(a) Remove the 2 bolts on the rear side of the seat. |

|

|

(b) Remove the 2 bolts on the front side of the seat. |

|

(c) Remove the rear seat assembly LH.

NOTICE:

Be careful not to damage the vehicle body.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE SEAT ADJUSTER COVER CAP LH

(a) Using a screwdriver wrapped with protective tape, disengage the 3

claws and remove the seat adjuster cover cap LH.

T ...

Other materials about Toyota Venza:

Inspection

INSPECTION

PROCEDURE

1. INSPECT GENERATOR PULLEY WITH CLUTCH

(a) Hold the center of the pulley, and confirm that the outer ring turns

counterclockwise and does not turn clockwise.

Text in Illustration

*1

...

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. REMOVE COOL AIR INTAKE DUCT SEAL

3. REMOVE NO. 1 ENGINE CO ...

Stop Light Switch

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE STOP LIGHT SWITCH ASSEMBLY

(a) Disconnect the connector.

(b) Turn the stop light switch assembly countercl ...

0.1368