Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL CHARCOAL CANISTER LEAK DETECTION PUMP SUB-ASSEMBLY

|

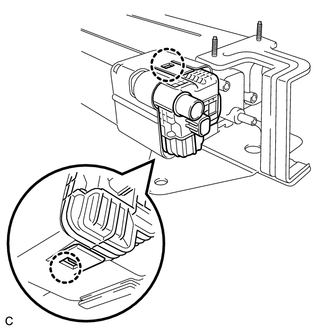

(a) Engage the 2 claws to install a new charcoal canister leak detection pump sub-assembly to the charcoal canister assembly. NOTICE:

|

|

2. INSTALL CHARCOAL CANISTER ASSEMBLY

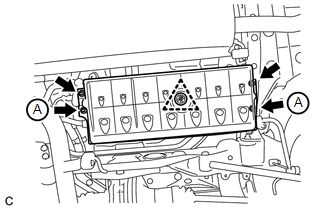

(a) Connect the 2 clips to install the charcoal canister assembly.

(b) Install the 4 nuts.

Torque:

5.5 N·m {56 kgf·cm, 49 in·lbf}

(c) Connect the air line tube to the charcoal canister leak detection pump sub-assembly.

NOTICE:

- Check that there are no scratches or foreign matter around the connecting parts of the tube connector and pipe before performing this work.

- After connecting the air line tube, check that the air line tube is securely connected by pulling on the tube connector and the charcoal canister.

(d) Connect the purge line hose to the charcoal canister assembly.

(e) Connect the connector to the charcoal canister leak detection pump sub-assembly.

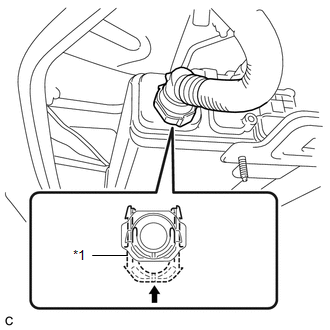

(f) Push in the tube connector to the pipe and push up the retainer to connect the vent line tube.

Text in Illustration

Text in Illustration

|

*1 |

Retainer |

.png) |

Push Up |

NOTICE:

- Check that there are no scratches or foreign matter around the connecting parts of the tube connector and pipe before performing this work.

- After connecting the vent line tube, check that the vent line tube is securely connected by pulling on the tube connector and the charcoal canister.

3. INSTALL NO. 1 FLOOR UNDER COVER

|

(a) Install the No. 1 floor under cover with the 4 nuts and clip. Torque: Nut A : 2.2 N·m {22 kgf·cm, 19 in·lbf} HINT: The 4 nuts and clip are attached to the No. 1 floor under cover. |

|

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT CHARCOAL CANISTER ASSEMBLY

(a) Visually check the charcoal canister assembly.

(1) Visually check the charcoal canister assembly for cracks or damage.

...

Emission Control System

Emission Control System

Parts Location

PARTS LOCATION

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT FUEL CUT-OFF RPM

(a) Increase the engine speed to at least 3500 rpm.

...

Other materials about Toyota Venza:

System Diagram

SYSTEM DIAGRAM

Input and Output Signal of Each ECU

Transmitting ECU (transmitter)

Receiving ECU

Signal

Communication Method

Power management Control ECU

Steering Lock ECU (Steering Lock ...

Front Passenger Side Door Entry Lock and Unlock Functions do not Operate

DESCRIPTION

When the entry lock and unlock functions do not operate only for the front passenger

door, an error in output request codes from the front passenger door or malfunction

in the front door outside handle assembly is suspected. If the entry funct ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT BRAKE DISC INSIDE DIAMETER

(a) Using a brake drum gauge or an equivalent tool, measure the inside

diameter of the disc.

Standard inside diameter of a new disc:

190 mm (7.48 in.)

Maximum inside diamete ...

0.1339