Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT CHARCOAL CANISTER ASSEMBLY

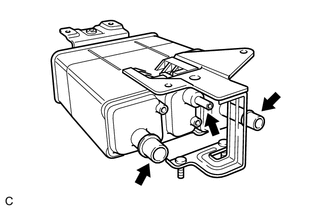

(a) Visually check the charcoal canister assembly.

|

(1) Visually check the charcoal canister assembly for cracks or damage. If cracks or damage are found, replace the charcoal canister assembly. |

|

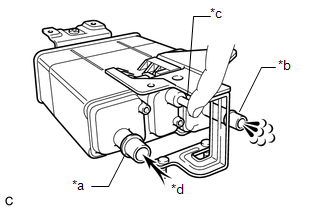

(b) Check canister operation.

|

(1) With the purge line port closed, blow 0.5 kPa (0.005 kgf/cm2, 0.1 psi) of air into the vent line port, and check that air flows from the air line port. Text in Illustration

If the result is not as specified, replace the charcoal canister assembly. |

|

|

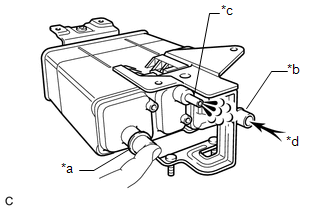

(2) With the vent line port closed, blow 0.5 kPa (0.005 kgf/cm2, 0.1 psi) of air into the air line port, and check that air flows from the purge line port. Text in Illustration

If the result is not as specified, replace the charcoal canister assembly. |

|

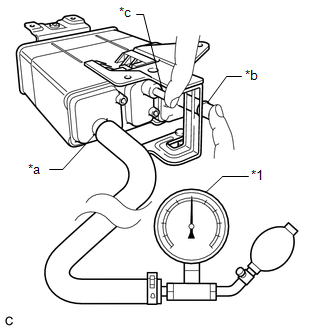

(c) Check for air leaks.

|

(1) Connect a pressure gauge to the vent line port of the charcoal canister assembly. Text in Illustration

|

|

(2) With the purge line port and the air line port closed, apply 20 kPa (150 mmHg, 5.91 in.Hg) of pressurized air into the vent line port, then confirm that pressure is retained for 1 minute.

If the result is not as specified, replace the charcoal canister assembly.

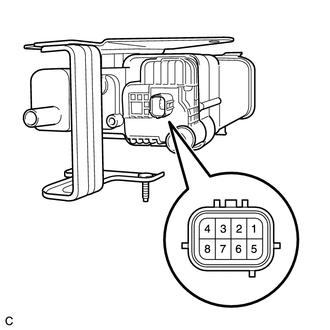

(d) Check the charcoal canister leak detection pump sub-assembly.

|

(1) Connect a positive (+) lead from the battery to terminal 5 and a negative (-) lead to terminal 1. |

|

(2) Check that a clicking sound is heard from the charcoal canister leak detection pump sub-assembly.

If the result is not as specified, replace the charcoal canister leak detection pump sub-assembly.

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 FLOOR UNDER COVER

(a) Disengage the 4 nuts and clip, and remove the No. 1 floor under cover.

Text in Illustration

Nut (attached to under cov ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL CHARCOAL CANISTER LEAK DETECTION PUMP SUB-ASSEMBLY

(a) Engage the 2 claws to install a new charcoal canister leak detection

pump sub-assembly to the ...

Other materials about Toyota Venza:

Front Passenger Side Door Entry Lock and Unlock Functions do not Operate

DESCRIPTION

When the entry lock and unlock functions do not operate only for the front passenger

door, an error in output request codes from the front passenger door or malfunction

in the front door outside handle assembly is suspected. If the entry funct ...

Air Conditioning Panel

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL AIR CONDITIONING CONTROL ASSEMBLY

(a) Connect the connector.

(b) Engage the 2 clips and 4 guides.

(c) Rem ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

0.1626