Toyota Venza: Installation

INSTALLATION

PROCEDURE

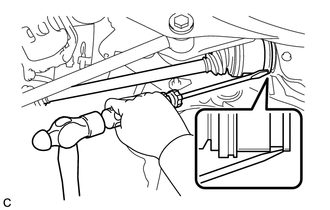

1. INSTALL REAR DRIVE SHAFT ASSEMBLY

|

(a) Align the shaft splines and install the rear drive shaft assembly using a screwdriver and hammer. NOTICE:

|

|

2. INSTALL REAR AXLE CARRIER SUB-ASSEMBLY

.gif)

3. INSPECT REAR STRUT ROD ASSEMBLY

.gif)

4. INSTALL NO. 3 PARKING BRAKE CABLE ASSEMBLY

.gif)

5. INSTALL REAR AXLE HUB AND BEARING ASSEMBLY

.gif)

6. INSTALL REAR SPEED SENSOR

.gif)

7. INSTALL REAR DISC

.gif)

8. INSTALL REAR DISC BRAKE CALIPER ASSEMBLY

.gif)

9. INSTALL REAR AXLE SHAFT NUT

(a) Clean the threaded parts on the drive shaft and axle shaft nut using a non-residue solvent.

NOTICE:

- Be sure to perform this work for a new drive shaft.

- Keep the threaded parts free of oil and foreign objects.

|

(b) Install a new rear axle shaft nut. Torque: 294 N·m {2998 kgf·cm, 217 ft·lbf} |

|

(c) Using a chisel and hammer, stake the rear axle shaft nut.

10. INSTALL REAR WHEEL

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

11. STABILIZE SUSPENSION

.gif)

12. INSPECT AND ADJUST DIFFERENTIAL OIL

.gif)

13. INSPECT AND ADJUST REAR WHEEL ALIGNMENT

HINT:

(See page .gif) )

)

14. CHECK ABS SPEED SENSOR SIGNAL

HINT:

(See page .gif) )

)

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL REAR DRIVE SHAFT DUST COVER

(a) Using SST and a steel plate, install a new rear drive shaft dust

cover to the rear drive shaft inboard joint assembly. ...

Other materials about Toyota Venza:

Terminals Of Ecu

TERMINALS OF ECU

1. CHECK TRANSPONDER KEY AMPLIFIER

(a) Disconnect the D21 transponder key amplifier connector.

(b) Measure the resistance according to the value(s) in the table below.

HINT:

Measure the values on the wire harness side with connector dis ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL SHIFT SOLENOID VALVE SL4

(a) Coat the shift solenoid valve SL4 and bolt with ATF.

Text in Illustration

*1

Lock Plate

*2

Solenoid V ...

System Diagram

SYSTEM DIAGRAM

Communication Table

Transmitting ECU

(Transmitter)

Receiving ECU

(Receiver)

Signal

Communication Method

Combination meter

Power management control ECU

...

0.1142

.png)