Toyota Venza: Inspection

INSPECTION

PROCEDURE

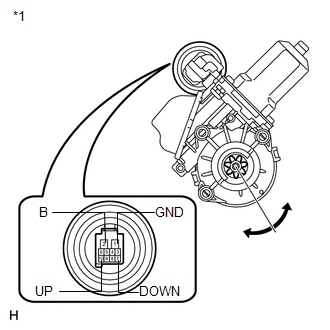

1. INSPECT FRONT POWER WINDOW REGULATOR MOTOR ASSEMBLY LH

|

(a) Apply positive (+) battery voltage to connector terminal 2 (B). NOTICE: Do not apply positive (+) battery voltage to any terminals other than terminal 2 (B) to avoid damaging the pulse sensor inside the motor. |

|

(b) Connect a ground lead to connector terminals 1 (GND) and 7 (DOWN) or 10 (UP).

(c) Check that the motor gear rotates smoothly as follows:

OK:

|

Measurement Condition |

Specified Condition |

|---|---|

|

Motor gear rotates clockwise (Up) |

|

Motor gear rotates counterclockwise (Down) |

|

*1 |

Component without harness connected (to Front Power Window Regulator Motor Assembly LH) |

- If the result is not as specified, replace the front power window regulator motor assembly LH.

CAUTION:

Reset the power window regulator motor (initialize the pulse sensor) after installing the power window regulator motor and regulator assembly onto the door.

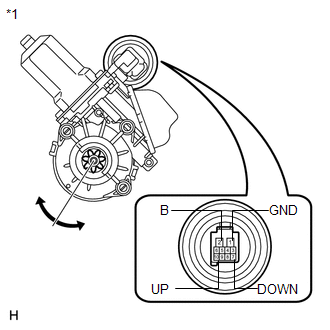

2. INSPECT FRONT POWER WINDOW REGULATOR MOTOR ASSEMBLY RH

|

(a) Apply positive (+) battery voltage to connector terminal 2 (B). NOTICE: Do not apply positive (+) battery voltage to any terminals other than terminal 2 (B) to avoid damaging the pulse sensor inside the motor. |

|

(b) Connect a ground lead to connector terminals 1 (GND) and 7 (DOWN) or 10 (UP).

(c) Check that the motor gear rotates smoothly as follows:

OK:

|

Measurement Condition |

Specified Condition |

|---|---|

|

Motor gear rotates counterclockwise (Up) |

|

Motor gear rotates clockwise (Down) |

|

*1 |

Component without harness connected (to Front Power Window Regulator Motor Assembly RH) |

- If the result is not as specified, replace the front power window regulator motor assembly RH.

CAUTION:

Reset the power window regulator motor (initialize the pulse sensor) after installing the power window regulator motor and regulator assembly onto the door.

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. DISCONNECT CABLE FROM NEGAT ...

Installation

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. INSTALL FRONT POWER WI ...

Other materials about Toyota Venza:

How To Use This Manual

General Information

GENERAL INFORMATION

1. GENERAL DESCRIPTION

(a) This manual is written in accordance with SAE J2008.

(b) Repair operations can be separated mainly into the following 3 processes:

(1) Diagnosis

(2) Removing / Installing, Replacing, Di ...

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Removal

REMOVAL

PROCEDURE

1. REMOVE FUEL SUCTION TUBE ASSEMBLY WITH PUMP AND GAUGE

(a) Remove the fuel suction tube assembly with pump and gauge (See page

).

2. REMOVE FUEL SENDER GAUGE

3. REMOVE FUEL FILTER ASSEMBLY

(a) Disconnect the fuel pump ...

0.1545