Toyota Venza: Inspection

INSPECTION

PROCEDURE

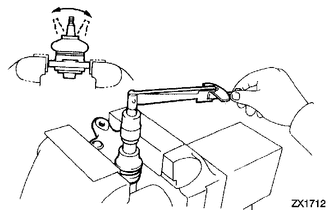

1. INSPECT FRONT LOWER BALL JOINT

|

(a) Inspect the turning torque of the ball joint. (1) Secure the front lower ball joint in a vise using aluminum plates. (2) Install the nut to the front lower ball joint stud. (3) Using a torque wrench, turn the nut continuously at a rate of 3 to 5 seconds per turn and take the torque reading on the 5th turn. Turning torque: 0.7 to 4.5 N*m (7 to 46 kgf*cm, 6.2 to 40 in.*lbf) If the turning torque is not within the specified range, replace the front lower ball joint with a new one. |

|

(b) Inspect the dust cover.

(1) Check that the dust cover is not cracked and that there is no grease on it.

Components

Components

COMPONENTS

ILLUSTRATION

...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the LH side and RH side.

The following procedure listed is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. ...

Other materials about Toyota Venza:

Terminals Of Ecm

TERMINALS OF ECM

1. CHECK ECM

Terminal No. (Symbol)

Wiring Color

Terminal Description

Condition

Specified Condition

A49-7 (TC) - B58-104 (E1)

V - BR

Terminal TC o ...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE MAGNETIC CLUTCH ASSEMBLY

(a) Place the compressor and magnetic clutch in a vise.

(b) Using SST, hold the magnetic clutch hub.

SST: 09985-00270

(c) Remove the bolt, ...

Front Door Courtesy Switch

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT COURTESY LIGHT SWITCH

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Switch C ...

0.1328