Toyota Venza: Inspection

INSPECTION

PROCEDURE

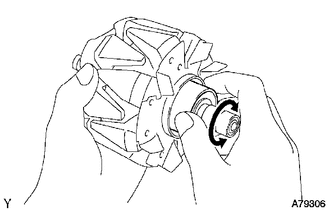

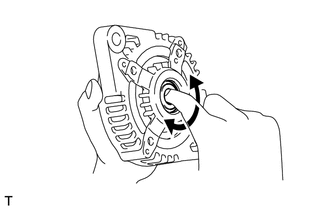

1. INSPECT GENERATOR CLUTCH PULLEY

|

(a) Hold the generator rotor using SST, and turn the clutch pulley clockwise to check that the outer ring locks. SST: 09820-63021 Text in Illustration

If the result is not as specified, replace the clutch pulley. |

|

2. INSPECT GENERATOR DRIVE END FRAME BEARING

|

(a) Check that the bearing is not rough or worn. OK: The bearing rotates smoothly. If the bearing does not rotate smoothly, replace the bearing. |

|

3. INSPECT GENERATOR BRUSH HOLDER ASSEMBLY

|

(a) Using a vernier caliper, measure the length of the exposed brushes. Text in Illustration

Standard exposed brush length: 9.5 to 11.5 mm (0.375 to 0.452 in.) Minimum exposed brush length: 4.5 mm (0.178 in.) If the exposed brush length is less than the minimum, replace the brush holder assembly. |

|

4. INSPECT GENERATOR ROTOR ASSEMBLY

|

(a) Check that the generator rotor bearing is not rough or worn. If necessary, replace the generator rotor assembly. |

|

|

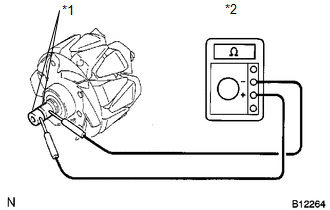

(b) Check the generator rotor for an open circuit. Text in Illustration

(1) Using an ohmmeter, measure the resistance between the slip rings. Standard Resistance:

If the result is not as specified, replace the generator rotor assembly. |

|

||||||||||||||

|

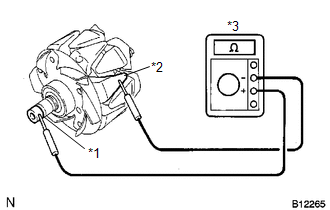

(c) Check the rotor for a short to ground. Text in Illustration

(1) Using an ohmmeter, measure the resistance between the slip ring and rotor. Standard Resistance:

If the result is not as specified, replace the generator rotor assembly. |

|

|

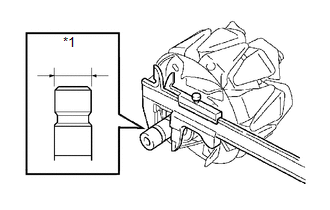

(d) Using a vernier caliper, measure the slip ring diameter. Text in Illustration

Standard diameter: 14.2 to 14.4 mm (0.560 to 0.566 in.) Minimum diameter: 14.0 mm (0.552 in.) If the diameter is less than the minimum, replace the generator rotor assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE GENERATOR REAR END COVER

(a) Remove the 3 nuts and generator rear end cover.

2. REMOVE TERMINAL INSULATOR

...

Replacement

Replacement

REPLACEMENT

PROCEDURE

1. REPLACE GENERATOR DRIVE END FRAME BEARING

(a) Remove the 4 screws and bearing retainer from the drive end frame.

...

Other materials about Toyota Venza:

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK RADIATOR CAP SUB-ASSEMBLY

(a) Measure the valve opening pressure.

(1) If there are water stains or foreign matter on rubber packings 1, 2 or 3,

clean the part(s) with water and finger scouring.

(2) Check that r ...

System Diagram

SYSTEM DIAGRAM

Communication Table

Transmitting ECU (Transmitter)

Receiving ECU

Signal

Communication Method

Main body ECU (Driver side junction block assembly)

Certification ECU (Sm ...

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

0.1379

.png)

.png)