Toyota Venza: Disassembly

DISASSEMBLY

PROCEDURE

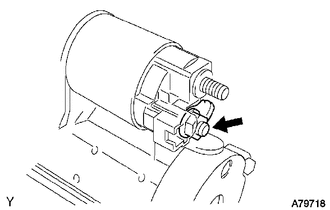

1. REMOVE MAGNETIC SWITCH ASSEMBLY

|

(a) Remove the nut and disconnect the lead wire from the magnetic switch. |

|

|

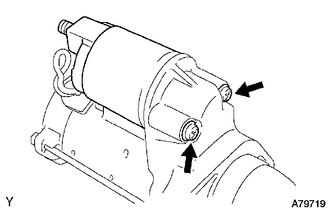

(b) Remove the 2 screws holding the magnetic switch to the starter drive housing. |

|

(c) Remove the magnetic switch.

(d) Remove the return spring and plunger from the starter drive housing.

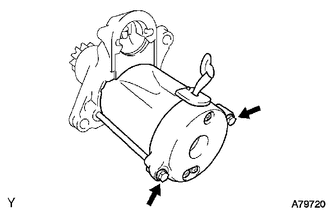

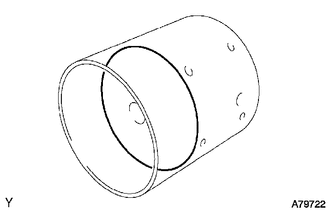

2. REMOVE STARTER YOKE ASSEMBLY

|

(a) Remove the 2 through-bolts, and pull out the starter yoke together with the commutator end frame. |

|

|

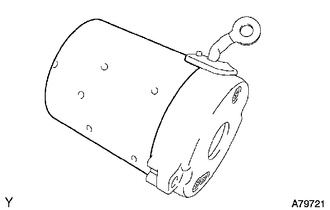

(b) Remove the starter yoke from the commutator end frame. |

|

3. REMOVE STARTER ARMATURE PLATE

|

(a) Remove the armature plate from the starter yoke. |

|

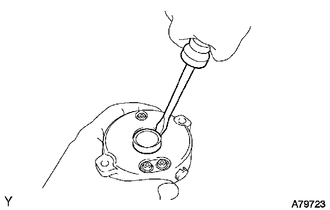

4. REMOVE STARTER COMMUTATOR END FRAME COVER

|

(a) Using a screwdriver, pry out the commutator end frame cover. |

|

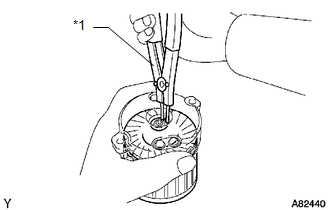

5. REMOVE STARTER ARMATURE ASSEMBLY

|

(a) Using snap ring pliers, remove the snap ring and plate washer. NOTICE: Do not drop the starter armature assembly. Text in Illustration

|

|

(b) Remove the armature from the commutator end frame.

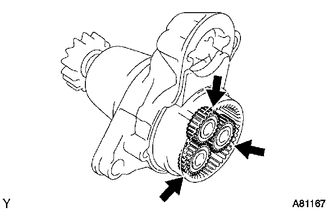

6. REMOVE PLANETARY GEAR

|

(a) Remove the 3 planetary gears from the starter drive housing. |

|

Removal

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. RE ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT STARTER ASSEMBLY

NOTICE:

These tests must be performed within 3 to 5 seconds to avoid burning out the

coil.

(a) Perform a pull-in test.

(1) Remove the nut and d ...

Other materials about Toyota Venza:

Precaution

PRECAUTION

1. NOTICE FOR INITIALIZATION

CAUTION:

When disconnecting the cable from the negative (-) battery terminal, initialize

the following system after the cable is reconnected.

System Name

See Procedure

Back Do ...

4wd Control Ecu

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT DOOR SCUFF PLATE RH

2. REMOVE COWL SIDE TRIM SUB-ASSEMBLY RH

3. REMOVE NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

4. REMOVE LOWER INSTRUMENT PANEL SUB-ASSEMBLY

...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

0.1409