Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT ENGINE SWITCH

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

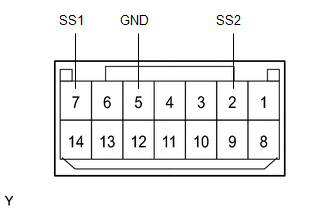

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

7 (SS1) - 5 (GND) |

Not pushed |

10 kΩ or higher |

|

2 (SS2) - 5 (GND) |

Not pushed |

10 kΩ or higher |

|

7 (SS1) - 5 (GND) |

Pushed |

15 Ω |

|

2 (SS2) - 5 (GND) |

Pushed |

15 Ω |

If the result is not as specified, replace the engine switch.

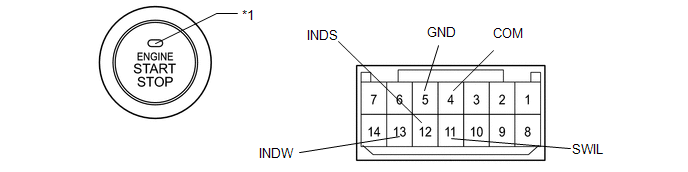

(b) Apply battery voltage between the terminals of the switch, and check the illumination condition of the engine switch.

HINT:

- If a positive (+) battery lead and a negative (-) battery lead are incorrectly connected, the engine switch indicator light will not illuminate.

- If the voltage is too low, the indicator light will not illuminate.

OK:

|

Measurement Condition |

Specified Condition |

|---|---|

|

Battery positive (+) → Terminal 11 (SWIL) Battery negative (-) → Terminal 4 (COM) or 5 (GND) |

Illuminates |

|

Battery positive (+) → Terminal 12 (INDS) Battery negative (-) → Terminal 4 (COM) or 5 (GND) |

Illuminates |

|

Battery positive (+) → Terminal 13 (INDW) Battery negative (-) → Terminal 4 (COM) or 5 (GND) |

Illuminates |

Text in Illustration

Text in Illustration

|

*1 |

Indicator Light |

If the result is not as specified, replace the engine switch.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. RE ...

Other materials about Toyota Venza:

Vehicle Speed Sensor "A" Intermittent / Erratic / High (P0503)

DESCRIPTION

If a malfunction (a rapid change in vehicle speed) in the vehicle speed signal

being output from the skid control ECU is detected while the cruise control is in

operation, the ECM determines that there is a momentary interruption or noise, and ...

Back Door Support

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR STAY ASSEMBLY

NOTICE:

Avoid touching the piston rod as much as possible to prevent foreign

matter from attaching to it. Be sure to hold the cylinder whil ...

Back Door Opener Switch

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

2. REMOVE REAR LIGHT ASSEMBLY LH

3. REMOVE REAR LIGHT ASSEMBLY RH

HINT:

Use the same procedure for the RH side and LH side.

4. REMOVE BA ...

0.1523