Toyota Venza: Inspection

INSPECTION

PROCEDURE

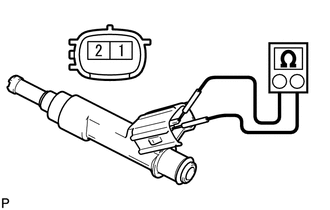

1. INSPECT FUEL INJECTOR ASSEMBLY

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the fuel injector assembly. |

|

(b) Inspect the injector injection.

CAUTION:

Keep the injector away from sparks during the test.

|

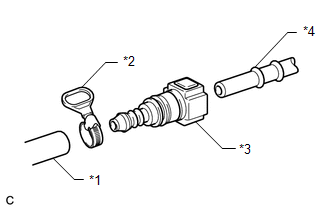

(1) Connect SST (fuel tube connector) to SST (hose) with SST (hose band), and then connect them to the fuel pipe (vehicle side). Text in Illustration

SST: 09268-31014 09268-41500 09268-41700 95336-08070 |

|

(2) Install a new O-ring to the fuel injector assembly.

|

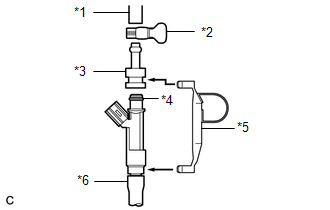

(3) Connect SST (adapter and hose) to the fuel injector assembly, and hold the fuel injector assembly and union with SST (clamp). Text in Illustration

SST: 09268-31014 09268-41110 09268-41300 09268-41700 95336-08070 |

|

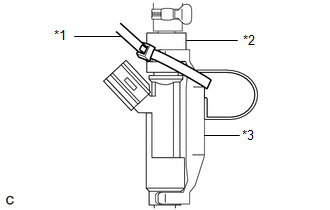

(4) Install a vinyl tube onto the fuel injector assembly.

CAUTION:

Install a suitable vinyl tube onto the injector to contain any gasoline spray.

|

(5) Tie the clamp and adapter together with SST (tie band) as shown in the illustration. Text in Illustration

SST: 09268-31014 09268-41110 09268-41300 09268-41800 |

|

(6) Put the fuel injector assembly into a graduated cylinder.

(7) Operate the fuel pump (See page .gif) ).

).

|

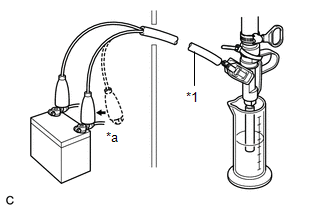

(8) Connect SST (wire) to the fuel injector assembly and the battery for 15 seconds, and measure the injection volume with the graduated cylinder. Test each fuel injector assembly 2 or 3 times. Text in Illustration

SST: 09842-30080 Standard Injection Volume:

Standard difference between each fuel injector assembly: 18 cc (1.1 cu. in.) or less If the result is not as specified, replace the fuel injector assembly. |

|

(c) Check for fuel drop.

(1) In the condition above, disconnect the tester probes of SST (wire) from the battery and check for fuel drop from the fuel injector assembly.

Standard fuel drop:

1 drop or less per 20 minutes

If fuel drop is not as specified, replace the fuel injector assembly.

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the fuel injector assembly

(See page ).

PROCEDURE

1. DISCHARGE FUEL SYSTEM PRESSURE

(a) Disch ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL FUEL INJECTOR ASSEMBLY

HINT:

Perform "Inspection After Repair" after replacing the fuel injector assembly

(See page ).

(a) Apply a light ...

Other materials about Toyota Venza:

Front Wiper Rubber

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. REMOVE FRONT WIPER BLADE

(a) Remove the holder of the front wiper blade.

(b) Remove the front wiper blade from the f ...

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR DOOR SCUFF PLATE LH

2. DISCONNECT REAR DOOR OPENING TRIM WEATHERSTRIP LH

3. REMOVE TONNEAU COVER ASSEMBLY (w/ Tonneau Cover)

4. REMOVE DECK BOARD ASSEMBLY

5. REMOVE NO. 3 DECK BOARD SUB-ASSEMBLY

6. REMOVE ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL AIR CONDITIONING UNIT ASSEMBLY

(a) Install the air conditioning unit assembly with the 3 nuts.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

NOTICE:

Tighten the nuts in the order shown in the illustration to install the ...

0.1571