Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL FUEL INJECTOR ASSEMBLY

HINT:

Perform "Inspection After Repair" after replacing the fuel injector assembly

(See page .gif) ).

).

|

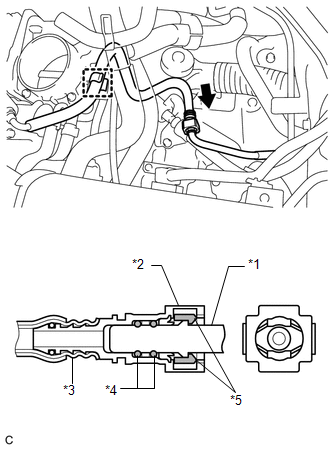

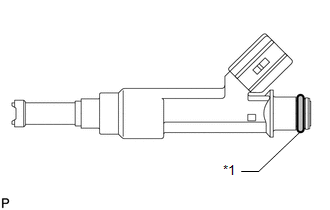

(a) Apply a light coat of gasoline or spindle oil to new O-rings, and then install one onto each fuel injector assembly. Text in Illustration

|

|

(b) Apply a light coat of gasoline or spindle oil to the contact surfaces of the new O-ring on each fuel injector assembly.

|

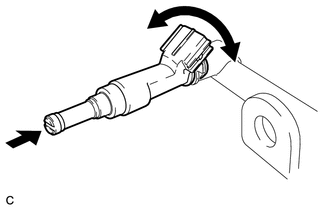

(c) While turning the fuel injector assembly left and right, install it onto the fuel delivery pipe sub-assembly. NOTICE: Make sure that the O-ring is not cracked or jammed when installing the

injector (See page |

|

(d) Check that the fuel injector rotates smoothly. If the fuel injector does not rotate, replace the O-ring.

2. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY

|

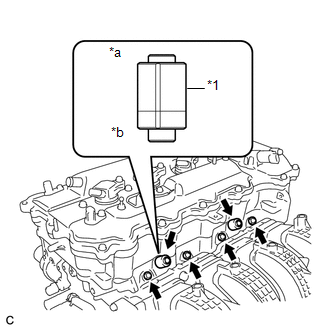

(a) Install 4 new injector vibration insulators to the cylinder head. Text in Illustration

|

|

(b) Install the 2 fuel delivery spacers onto the cylinder head.

HINT:

Install the fuel delivery spacer so that the longer protrusion is on the cylinder head side.

(c) Install the fuel delivery pipe sub-assembly together with the 4 fuel injectors to the cylinder head, and then temporarily install the 2 bolts.

NOTICE:

Be careful not to drop the fuel injectors when installing the fuel delivery pipe sub-assembly.

(d) Tighten the 2 bolts to the specified torque.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

NOTICE:

- Do not drop the fuel injectors when installing the fuel delivery pipe sub-assembly.

- Check that the fuel injector assemblies rotate smoothly after installing the fuel delivery pipe sub-assembly.

3. CONNECT WIRE HARNESS

|

(a) Install the 2 wire harness brackets with the 2 bolts. Torque: 8.4 N·m {85 kgf·cm, 74 in·lbf} |

|

(b) Connect the 2 connectors.

(c) Connect the 4 fuel injector connectors.

(d) Engage the clamp to connect the wire harness.

4. INSTALL VACUUM SWITCHING VALVE ASSEMBLY (for ACIS)

.gif)

5. CONNECT FUEL TUBE SUB-ASSEMBLY

(a) Push the fuel tube connector to the fuel pipe until the fuel tube connector makes a "click" sound.

Text in Illustration

Text in Illustration

|

*1 |

Fuel Pipe |

|

*2 |

Fuel Tube Connector |

|

*3 |

Nylon Tube |

|

*4 |

O-ring |

|

*5 |

Retainer |

.png) |

Push |

NOTICE:

- Before connecting the fuel tube connector and fuel pipe, check that there is no damage or foreign matter on the connecting part of the fuel pipe.

- After connecting the fuel tube connector and fuel pipe, check that they are securely connected by trying to pull them apart.

(b) Install the No. 1 fuel pipe clamp.

(c) Install the fuel tube sub-assembly to the fuel hose clamp.

6. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

.gif)

7. INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

.gif)

8. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

9. INSTALL OUTER COWL TOP PANEL

.gif)

10. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

(a) Install the windshield wiper motor and link assembly (See page

.gif) ).

).

11. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

12. INSPECT FOR FUEL LEAK

.gif)

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL INJECTOR ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connec ...

Other materials about Toyota Venza:

ACIS Control Circuit

DESCRIPTION

This circuit opens and closes the Intake Air Control Valve (IACV) in response

to the engine load in order to increase the intake efficiency (ACIS: Acoustic Control

Induction System).

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspe ...

Poor Sound Quality in All Modes (Low Volume)

PROCEDURE

1.

CHECK AUDIO SETTINGS

(a) Set treble, middle and bass to the initial values and check that the sound

is normal.

OK:

The sound returns to normal.

HINT:

Sound quality adjustment measures vary according to the ...

Speedometer Malfunction

DESCRIPTION

The meter CPU receives vehicle speed signals from the skid control ECU via the

CAN communication system (CAN No. 1 Bus). The speed sensor detects the wheel speed

and sends the appropriate signals to the skid control ECU. The skid control ECU

...

0.1544

.png)