Toyota Venza: Ignition Coil And Spark Plug

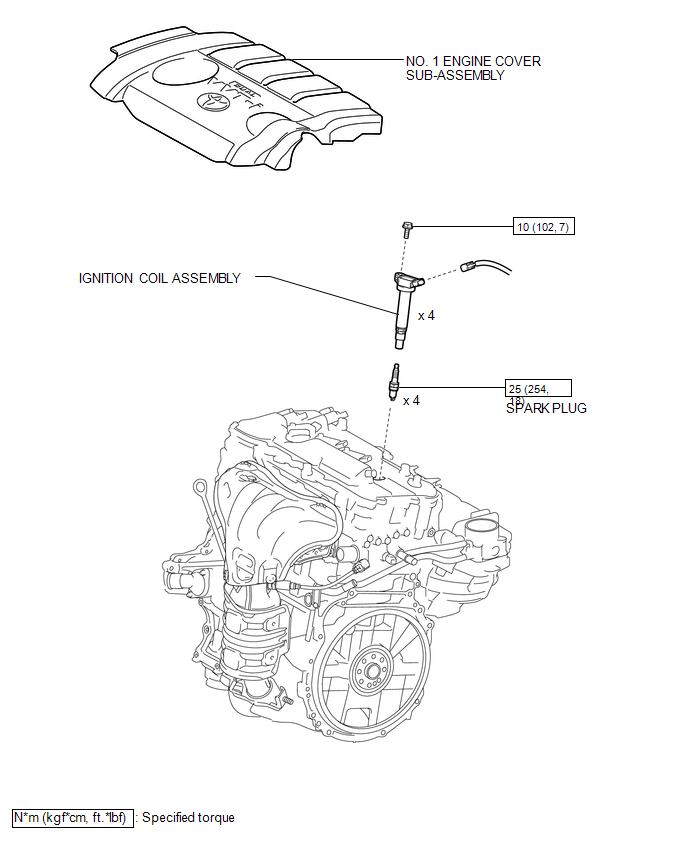

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

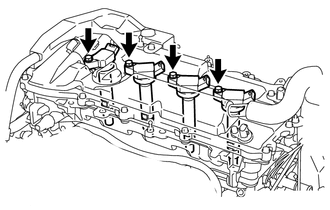

2. REMOVE IGNITION COIL ASSEMBLY

(a) Disconnect the 4 ignition coil assembly connectors.

|

(b) Remove the 4 bolts and 4 ignition coil assemblies. |

|

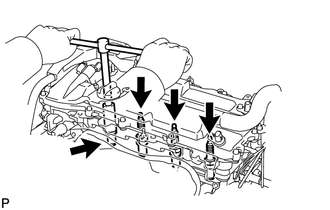

3. REMOVE SPARK PLUG

|

(a) Using a spark plug wrench, remove the 4 spark plugs. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL SPARK PLUG

|

(a) Using a spark plug wrench, install the 4 spark plugs. Torque: 25 N·m {254 kgf·cm, 18 ft·lbf} HINT: Perform "Inspection After Repair" after replacing the spark plugs (See

page |

|

2. INSTALL IGNITION COIL ASSEMBLY

|

(a) Install the 4 ignition coil assemblies with the 4 bolts. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} HINT: Perform "Inspection After Repair" after replacing an ignition coil assembly

(See page |

|

(b) Connect the 4 ignition coil assembly connectors.

3. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

Heated Oxygen Sensor

Heated Oxygen Sensor

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE UNDER COVER

2. REMOVE NO. 2 ENGINE UNDER COVER

3. REMOVE FRONT EXHAUST PIPE ASSEMBLY

4. REMOVE HEA ...

Ignition System

Ignition System

...

Other materials about Toyota Venza:

Operation Check

OPERATION CHECK

1. INSPECT ILLUMINATED ENTRY SYSTEM OPERATION

NOTICE:

Perform this inspection with the customize parameters at the initial setting.

HINT:

The interior light control illuminates the lights below.

Transponder Key Amplifier*1

Roof ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL STUD BOLT (for LH Side)

(a) Install the stud bolt.

Torque:

17 N·m {173 kgf·cm, 13 ft·lbf}

2. INSTALL STUD BOLT (for RH Side)

HINT:

Perform the same proc ...

Fuel Receiver Gauge Malfunction

DESCRIPTION

The meter CPU uses the fuel sender gauge assembly to determine the level

of the fuel in the fuel tank. The resistance of the fuel sender gauge will

vary between approximately 7.5 Ω with the float at the full position, and

185 Î ...

0.1302

.png)

.png)