Toyota Venza: Heated Oxygen Sensor

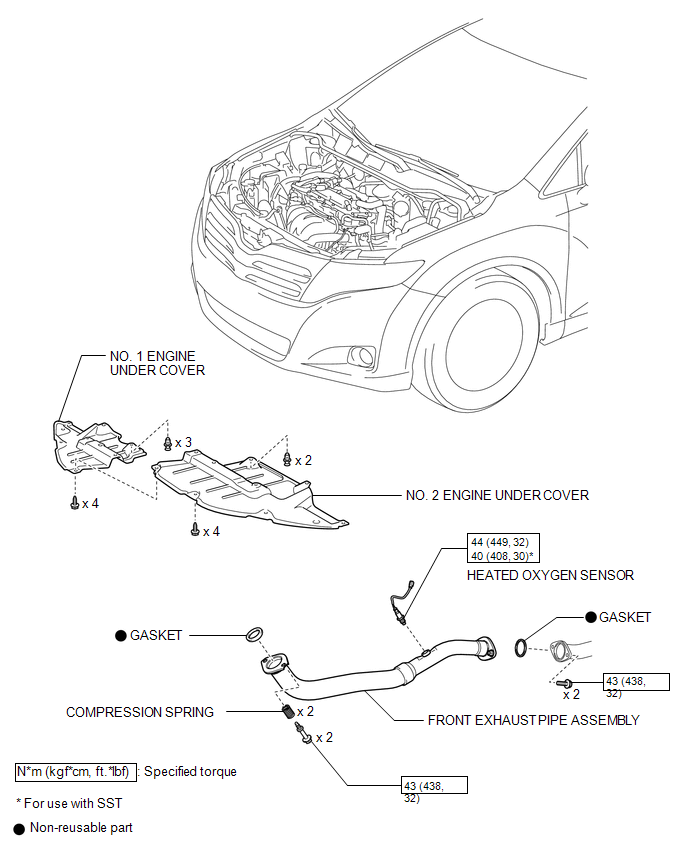

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE UNDER COVER

2. REMOVE NO. 2 ENGINE UNDER COVER

3. REMOVE FRONT EXHAUST PIPE ASSEMBLY

.gif)

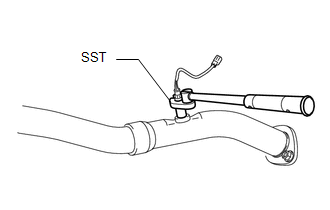

4. REMOVE HEATED OXYGEN SENSOR

|

(a) Using SST, remove the heated oxygen sensor from the front exhaust pipe assembly. SST: 09224-00011 |

|

Inspection

INSPECTION

PROCEDURE

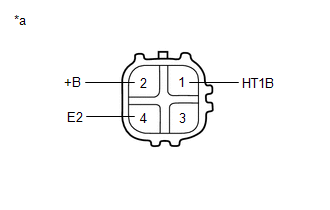

1. INSPECT HEATED OXYGEN SENSOR

|

(a) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

If the result is not as specified, replace the heated oxygen sensor. |

|

Installation

INSTALLATION

PROCEDURE

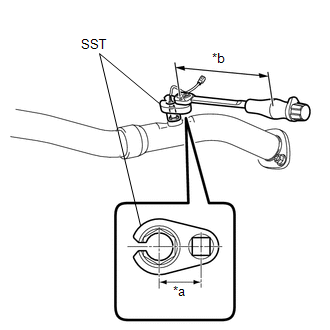

1. INSTALL HEATED OXYGEN SENSOR

HINT:

Perform "Inspection After Repair" after replacing the heated oxygen sensor (See

page .gif) ).

).

|

(a) Using SST, install the heated oxygen sensor to the front exhaust pipe assembly. Text in Illustration

SST: 09224-00011 Torque: without SST [Torque (N*m (kgf*cm, ft.*lbf))] : 44 N·m {449 kgf·cm, 32 ft·lbf} with SST [Reading of Torque wrench (N*m (kgf*cm, ft.*lbf))] : 40 N·m {408 kgf·cm, 30 ft·lbf} NOTICE: If the heated oxygen sensor has been struck or dropped, replace it. HINT:

|

|

2. INSTALL FRONT EXHAUST PIPE ASSEMBLY

.gif)

3. INSPECT FOR EXHAUST GAS LEAK

4. INSTALL NO. 2 ENGINE UNDER COVER

5. INSTALL NO. 1 ENGINE UNDER COVER

6. PERFORM INITIALIZATION

(a) Perform "Inspection After Repair" after replacing the heated oxygen sensor

(See page .gif) ).

).

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL ENGINE COOLANT TEMPERATURE SENSOR

(a) Install a new gasket to the sensor.

Text in Illustration

*1

New Gasket

...

Ignition Coil And Spark Plug

Ignition Coil And Spark Plug

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

2. REMOVE IGNITION COIL ASSEMBLY

(a) Disconnect the 4 ignition coil assembly con ...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL HOOD LOCK CONTROL CABLE ASSEMBLY

(a) Pass the hood lock control cable assembly into the engine compartment.

(b) Pass the cable through the upper radiator support.

(c) Engage the each clamp shown in the illustration.

2. I ...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure to troubleshoot the audio and visual system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

...

Receiver Error (C2176/76)

DESCRIPTION

The signals are transmitted to the tire pressure warning antenna and receiver

on the body as radio waves and then sent to the tire pressure warning ECU.

DTC No.

DTC Detection Condition

Trouble Area

...

0.1509