Toyota Venza: Entire Combination Meter does not Operate

DESCRIPTION

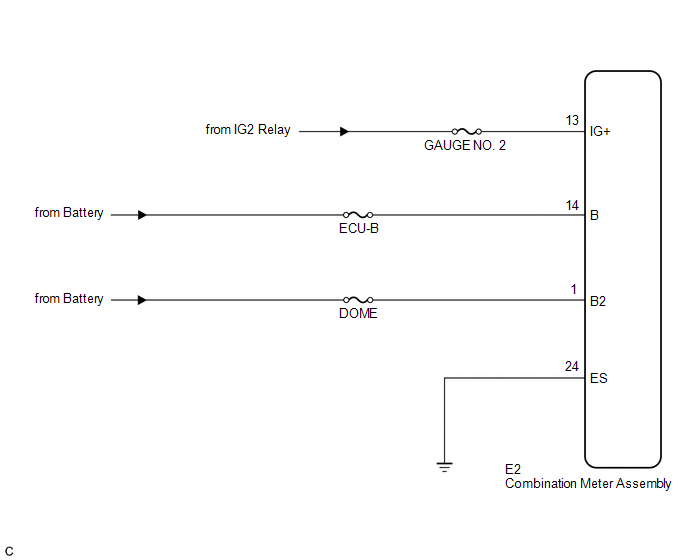

This circuit is the power source circuit for the meter. This circuit provides two types of power sources; one is a constant power source mainly used as a backup power source, and the other is an IG power source mainly used for signal transmission. The constant power source is mainly used as a backup power source for the meter CPU, however, it is also used for CAN communication. If a voltage of 12 V is not applied to terminal IG2 when the ignition switch is turned to ON, the indicator will not operate.

WIRING DIAGRAM

PROCEDURE

|

1. |

INSPECT COMBINATION METER ASSEMBLY |

|

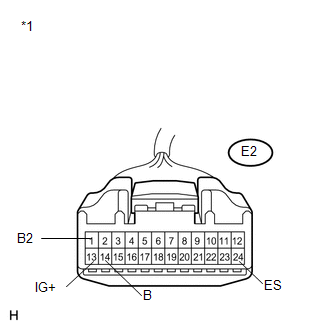

(a) Disconnect the E2 connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E2-24 (ES) - Body ground |

Always |

Below 1 Ω |

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E2-13 (IG+) - Body ground |

Ignition switch ON |

11 to 14 V |

|

E2-1 (B2) - Body ground |

Always |

11 to 14 V |

|

E2-14 (B) - Body ground |

Always |

11 to 14 V |

|

*1 |

Front view of wire harness connector (to Combination Meter Assembly) |

| OK | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Lost Communication with ECM / PCM "A" (U0100,U0129)

Lost Communication with ECM / PCM "A" (U0100,U0129)

DESCRIPTION

The combination meter assembly communicates with the ECM via the CAN communication

system (CAN No. 1 Bus).

DTC No.

DTC Detection Condition

Trouble Area ...

Speedometer Malfunction

Speedometer Malfunction

DESCRIPTION

The meter CPU receives vehicle speed signals from the skid control ECU via the

CAN communication system (CAN No. 1 Bus). The speed sensor detects the wheel speed

and sends the appropr ...

Other materials about Toyota Venza:

Driver Side Power Window does not Operate with Power Window Master Switch

DESCRIPTION

When the engine is running or the ignition switch is ON, the power window regulator

motor assembly (for driver side) is operated by the power window regulator master

switch assembly. The power window regulator motor assembly (for driver side) ...

Automatic transmission

Select a shift position appropriate for the driving conditions.

- Shifting the shift lever

Vehicles with smart key system:

While the “ENGINE START STOP” switch is in IGNITION ON mode, depress the brake

pedal and move the shift lever.

Vehicles ...

Lost Communication with TCM (U0101)

DESCRIPTION

The Transmission Control Module (TCM) and ECM perform 2-way communication with

each other via the Controller Area Network (CAN). The TCM sends signals to the ECM

concerning required engine speed, required engine torque, warning indicators in

...

0.1457