Toyota Venza: Fuel Sender Open Detected (B1500)

DESCRIPTION

This DTC is output when the combination meter assembly detects a fuel sender gauge malfunction via the direct line.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B1500 |

When either of the following conditions is detected:

|

|

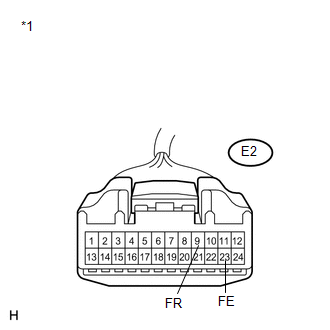

WIRING DIAGRAM

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (FUEL INPUT) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter following menus: Body Electrical / Combination Meter / Data List.

(e) Check the values by referring to the table below.

Combination Meter|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Fuel Input |

Fuel input signal/Min.: 0, Max.: 127.5 |

The current fuel level displayed |

Unit: Liter |

|

Result |

Proceed to |

|---|---|

|

Fuel level data can be displayed on the Techstream and DTC B1500 is output. |

A |

|

Fuel level data cannot be displayed on the Techstream. |

B |

| A | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

|

|

2. |

INSPECT COMBINATION METER ASSEMBLY |

|

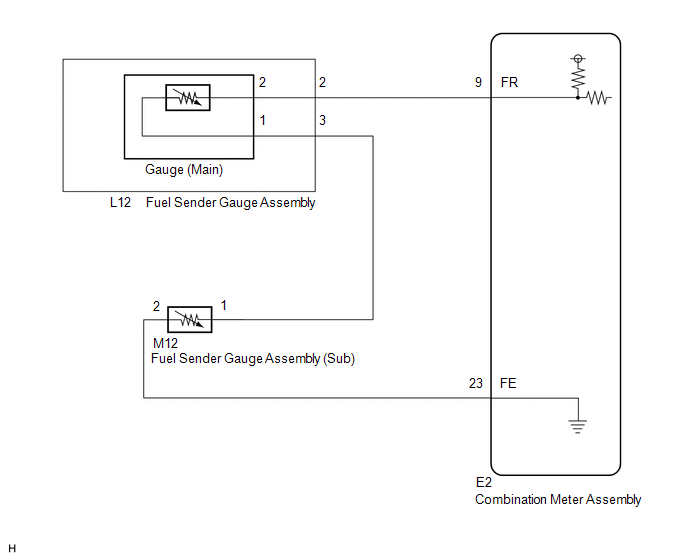

(a) Disconnect the E2 connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E2-9 (FR) - E2-23 (FE) |

Always |

6.5 to 187.2 Ω*1 |

|

E2-9 (FR) - E2-23 (FE) |

Always |

6.5 to 227.3 Ω*2 |

- *1: for Fuel Sender Gauge Assembly (Main)

- *2: for Fuel Sender Gauge Assembly (Sub)

|

*1 |

Front view of wire harness connector (to Combination Meter Assembly) |

| OK | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

|

|

3. |

CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - FUEL SENDER GAUGE ASSEMBLY) |

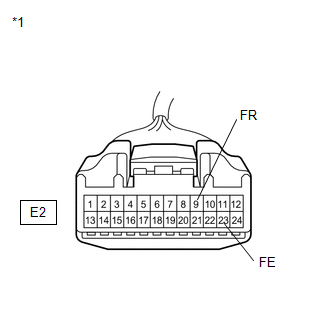

(a) Disconnect the L12 connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E2-9 (FR) - L12-2 |

Always |

Below 1 Ω |

|

E2-9 (FR) - Body ground |

Always |

10 kΩ or higher |

|

E2-23 (FE) - M12-2 |

Always |

Below 1 Ω |

|

E2-23 (FE) - Body ground |

Always |

10 kΩ or higher |

|

L12-3 - M12-1 |

Always |

Below 1 Ω |

|

M12-1 - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Combination Meter Assembly) |

|

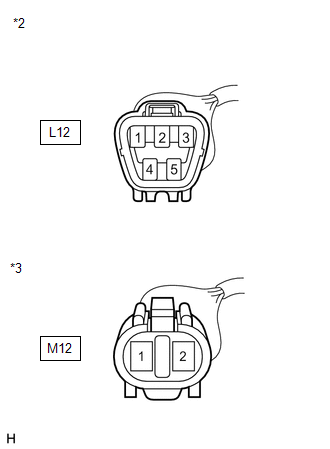

*2 |

Front view of wire harness connector (to Fuel Sender Gauge Assembly (Main)) |

|

*3 |

Front view of wire harness connector (to Fuel Sender Gauge Assembly (Sub)) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

INSPECT FUEL SENDER GAUGE ASSEMBLY |

(a) Remove the fuel sender gauge assembly (See page

.gif) (Main),

(Main), .gif)

(Sub)).

(b) Check that the float moves smoothly between E and F.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Main):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

Float level is F (upper) |

6.5 to 8.5 Ω |

|

1 - 2 |

Float level is between F (upper) and E (lower) |

6.5 to 187.2 Ω (Gradually changes) |

|

1 - 2 |

Float level is E (lower) |

183.2 to 187.2 Ω |

Standard Resistance (Sub):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

Float level is F (upper) |

6.5 to 8.5 Ω |

|

1 - 2 |

Float level is between F (upper) and E (lower) |

6.5 to 227.3 Ω (Gradually changes) |

|

1 - 2 |

Float level is E (lower) |

222.3 to 227.3 Ω |

|

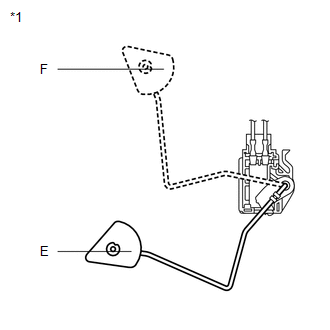

*1 |

Front view of wire harness connector (to Fuel Sender Gauge Assembly (Main)) |

|

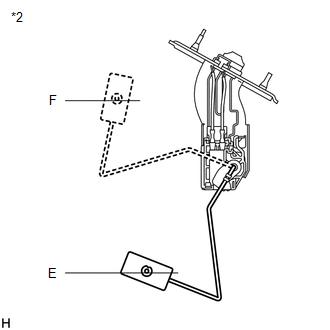

*2 |

Front view of wire harness connector (to Fuel Sender Gauge Assembly (Sub)) |

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (for 2GR-FE) |

B |

|

NG (for 1AR-FE) |

C |

| B | .gif) |

REPLACE FUEL SENDER GAUGE ASSEMBLY (for 2GR-FE) |

| C | .gif) |

REPLACE FUEL SENDER GAUGE ASSEMBLY (for 1AR-FE) |

|

|

5. |

CHECK FUEL SENDER GAUGE ASSEMBLY |

(a) Visually check for deformation on the fuel sender gauge assembly connector.

OK:

There is no deformation.

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (for 2GR-FE) |

B |

|

NG (for 1AR-FE) |

C |

| A | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

| B | .gif) |

REPLACE FUEL SENDER GAUGE ASSEMBLY (for 2GR-FE) |

| C | .gif) |

REPLACE FUEL SENDER GAUGE ASSEMBLY (for 1AR-FE) |

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT SPEEDOMETER

(a) Check the operation.

(1) Using a speedometer tester (calibrated chassis dynamometer), check the speedometer

indication according to the ...

Lost Communication with ECM / PCM "A" (U0100,U0129)

Lost Communication with ECM / PCM "A" (U0100,U0129)

DESCRIPTION

The combination meter assembly communicates with the ECM via the CAN communication

system (CAN No. 1 Bus).

DTC No.

DTC Detection Condition

Trouble Area ...

Other materials about Toyota Venza:

Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

NOTICE:

When disassembling the multiplex network door ECU, eliminate static electricity

by touching the vehicle body to prevent the components from being damaged.

PROCEDURE

1. REMOVE MULTIPLEX NETWORK DOOR ECU

...

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR DOOR COURTESY LIGHT SWITCH

(a) Using "TORX" socket wrench T30, install the rear door courtesy light

switch with the "TORX" bolt.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

...

Driver Side Door ECU Communication Stop (B2321)

DESCRIPTION

This DTC is stored when LIN communication between the power window regulator

motor assembly (for driver side) and main body ECU (driver side junction block assembly)

stops for more than 10 seconds.

DTC No.

DTC Detection ...

0.115

.gif)