Toyota Venza: Disassembly

DISASSEMBLY

PROCEDURE

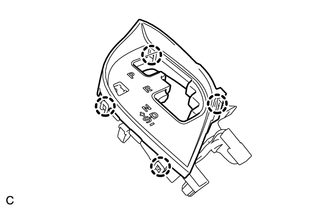

1. REMOVE POSITION INDICATOR HOUSING SUB-ASSEMBLY

(a) Remove the shift lever cap from the position indicator housing sub-assembly.

|

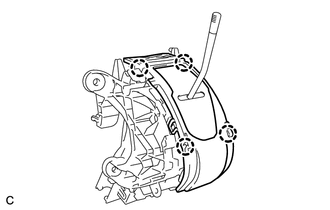

(b) Disengage the 4 claws and remove the position indicator housing sub-assembly. |

|

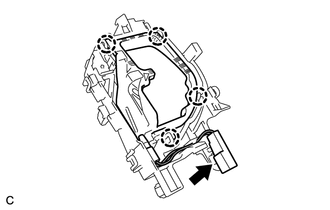

2. REMOVE POSITION INDICATOR LIGHT GUIDE

|

(a) Disengage the 4 claws and remove the position indicator connector and position indicator light guide. |

|

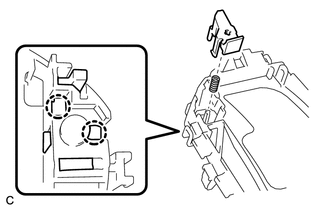

3. REMOVE SHIFT LOCK RELEASE BUTTON

|

(a) Disengage the 2 claws to remove the shift lock release button and compression spring. |

|

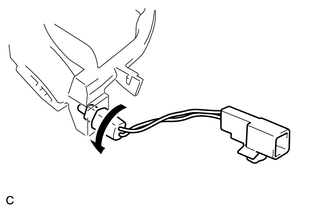

4. REMOVE INDICATOR LIGHT WIRE SUB-ASSEMBLY

|

(a) Remove the indicator light wire sub-assembly from the position indicator light guide. |

|

5. REMOVE POSITION INDICATOR LIGHT BULB

(a) Remove the position indicator light cap from the position indicator light bulb.

(b) Remove the position indicator light bulb from the indicator light wire sub-assembly.

6. REMOVE UPPER POSITION INDICATOR HOUSING

|

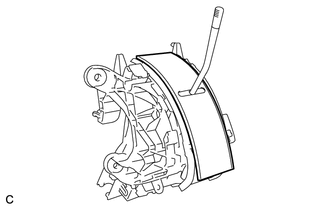

(a) Detach the 4 claws and remove the upper position indicator housing from the lower position indicator housing. |

|

7. REMOVE POSITION INDICATOR SLIDE COVER

|

(a) Remove the position indicator slide cover from the lower position indicator housing. |

|

8. REMOVE NO. 2 POSITION INDICATOR SLIDE COVER

(a) Remove the No. 2 position indicator slide cover from the position indicator slide cover.

9. REMOVE LOWER POSITION INDICATOR HOUSING

|

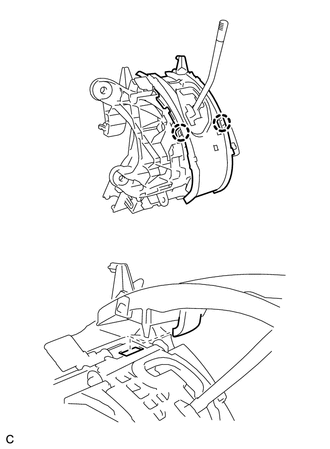

(a) Detach the 2 claws and remove the lower position indicator housing from the shift lock control unit assembly. |

|

10. REMOVE SHIFT LOCK CONTROL COMPUTER SUB-ASSEMBLY

|

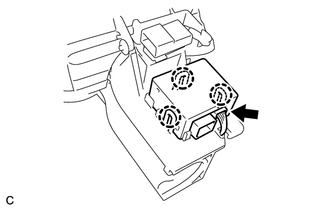

(a) Disconnect the connector from the shift lock control computer sub-assembly. |

|

(b) Detach the 3 claws and remove the shift lock control computer sub-assembly.

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY

(a) Inspect the shift lock operation.

(1) Move the shift lever to P.

(2) Turn the ignition switch off.

(3) Check that ...

Removal

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. RE ...

Other materials about Toyota Venza:

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT WINDSHIELD WIPER MOTOR ASSEMBLY

(a) for RH Side

(1) Operate the windshield wiper motor assembly.

(2) Stop the windshield wiper motor assembly operation.

...

Dtc Check / Clear

DTC CHECK / CLEAR

1. CHECK FOR TRANSPONDER KEY ECU DTC

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Immobiliser / Trouble Codes.

(e) Check the det ...

Rear Airbag Sensor RH Circuit Malfunction (B1630/23)

DESCRIPTION

The side collision sensor RH circuit (to determine deployment of the front seat

side airbag assembly RH and curtain shield airbag assembly RH) is composed of the

center airbag sensor assembly, rear airbag sensor RH and side airbag sensor RH.

...

0.1499