Toyota Venza: Disassembly

DISASSEMBLY

PROCEDURE

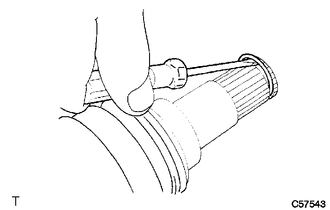

1. REMOVE FRONT DRIVE SHAFT HOLE SNAP RING (for LH Side)

|

(a) Using a screwdriver, remove the front drive shaft hole snap ring. |

|

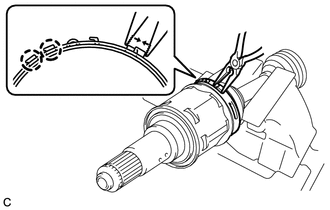

2. REMOVE NO. 2 FRONT AXLE INBOARD JOINT BOOT CLAMP (for 1AR-FE)

|

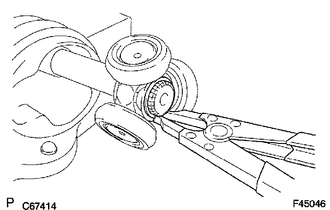

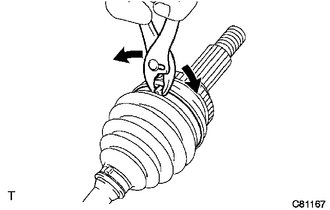

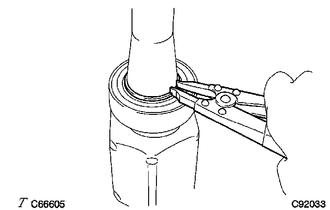

(a) Using needle-nose pliers, disengage the 2 claws to remove the No. 2 front axle inboard joint boot clamp as shown in the illustration. |

|

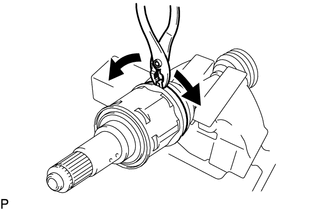

3. REMOVE NO. 2 FRONT AXLE INBOARD JOINT BOOT CLAMP (for 2GR-FE)

|

(a) Using pliers, remove the No. 2 front axle inboard joint boot clamp as shown in the illustration. |

|

4. REMOVE FRONT AXLE INBOARD JOINT BOOT CLAMP

(a) Remove the front axle inboard joint boot clamp.

HINT:

Perform the same procedure as for the No. 2 front axle inboard joint boot clamp (for 2GR-FE).

5. SEPARATE FRONT AXLE INBOARD JOINT BOOT

(a) Separate the front axle inboard joint boot from the inboard joint assembly.

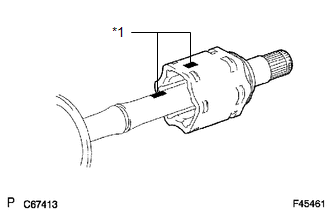

6. REMOVE FRONT DRIVE INBOARD JOINT ASSEMBLY

(a) Remove the grease from the inboard joint assembly.

|

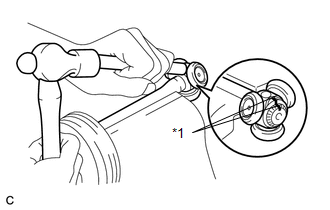

(b) Put matchmarks on the front drive inboard joint assembly and front drive outboard joint shaft assembly. Text in Illustration

NOTICE: Do not use a punch for the marks. |

|

(c) Remove the front drive inboard joint assembly from the front drive outboard joint shaft assembly.

|

(d) Using a snap ring expander, remove the shaft snap ring. |

|

|

(e) Put matchmarks on the outboard joint shaft and tripod joint. Text in Illustration

NOTICE: Do not use a punch for the marks. |

|

(f) Using a brass bar and a hammer, remove the tripod joint from the front drive outboard joint shaft assembly.

NOTICE:

Do not tap the roller.

7. REMOVE FRONT AXLE INBOARD JOINT BOOT

(a) Remove the front axle inboard joint boot from the front drive outboard joint shaft assembly.

8. REMOVE FRONT DRIVE SHAFT DAMPER (w/ 1 Clamp)

|

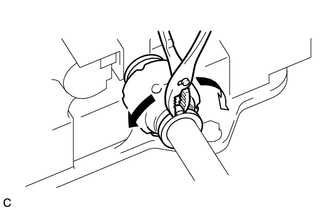

(a) Using pliers, separate the front drive shaft damper clamp as shown in the illustration. |

|

(b) Remove the front drive shaft damper and front drive shaft damper clamp.

9. REMOVE FRONT DRIVE SHAFT DAMPER (w/ 2 Clamps)

|

(a) Using needle-nose pliers, separate the 2 front drive shaft damper clamps as shown in the illustration. |

|

(b) Remove the front drive shaft damper and 2 front drive shaft damper clamps.

10. REMOVE NO. 2 FRONT AXLE OUTBOARD JOINT BOOT CLAMP

|

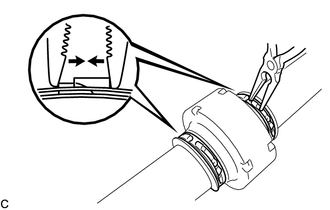

(a) Using pliers, remove the No. 2 front axle outboard joint boot clamp as shown in the illustration. |

|

11. REMOVE FRONT AXLE OUTBOARD JOINT BOOT CLAMP

(a) Remove the front axle outboard joint boot clamp.

HINT:

Perform the same procedure as for the No. 2 front axle outboard joint boot clamp.

12. REMOVE FRONT AXLE OUTBOARD JOINT BOOT

(a) Remove the front axle outboard joint boot from the front drive outboard joint shaft assembly.

(b) Remove the grease from the front drive outboard joint.

13. REMOVE FRONT DRIVE SHAFT DUST COVER LH (for LH Side)

|

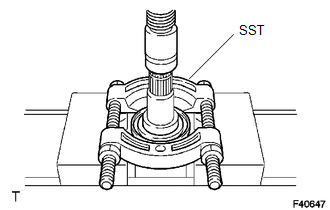

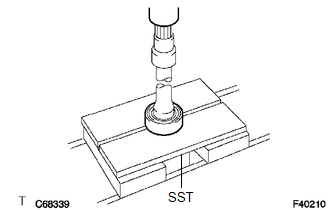

(a) Using SST and a press, remove the front drive shaft dust cover LH. SST: 09950-00020 NOTICE: Be careful not to drop the inboard joint assembly. |

|

14. REMOVE FRONT DRIVE SHAFT DUST COVER RH (for 2WD RH Side)

|

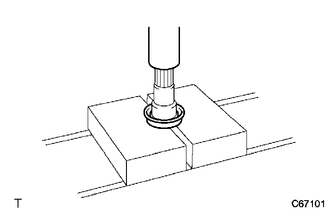

(a) Using a press, remove the front drive shaft dust cover RH. NOTICE: Be careful not to drop the inboard joint assembly. |

|

15. REMOVE FRONT DRIVE SHAFT DUST COVER (for 2WD RH Side)

|

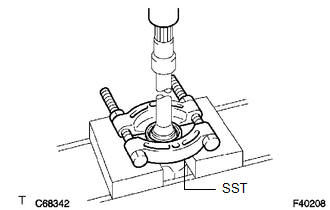

(a) Using SST and a press, remove the front drive shaft dust cover. SST: 09950-00020 NOTICE: Be careful not to drop the inboard joint assembly. |

|

16. REMOVE FRONT DRIVE SHAFT BEARING (for RH Side)

|

(a) Using a snap ring expander, remove the drive shaft hole snap ring. |

|

|

(b) Using SST and a press, remove the front drive shaft bearing. SST: 09527-10011 NOTICE: Be careful not to drop the inboard joint assembly. |

|

17. REMOVE BEARING BRACKET HOLE SNAP RING (for RH Side)

(a) Remove the bearing bracket hole snap ring.

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. PRECAUTION

HINT:

See page ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT DRIVE SHAFT ASSEMBLY

(a) Check whether the drive shaft dimensions are within the following

specifications.

Text in Illustration

...

Other materials about Toyota Venza:

Terminals Of Ecm

TERMINALS OF ECM

HINT:

The standard voltage between each pair of ECM terminals is shown in the table

below. The appropriate conditions for checking each pair of terminals are also indicated.

The result of checks should be compared with the standard vol ...

Uniform Tire Quality Grading

This information has been prepared in accordance with regulations issued by the

National Highway Traffic Safety Administration of the U.S. Department of Transportation.

It provides the purchasers and/or prospective purchasers of Toyota vehicles with

infor ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT NO. 1 ULTRASONIC SENSOR

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Condition

Specified ...

0.1705