Toyota Venza: Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The procedure listed below is for the LH side.

PROCEDURE

1. PRECAUTION

HINT:

See page .gif)

2. DRAIN AUTOMATIC TRANSAXLE FLUID

HINT:

- for U660E: See page

.gif)

- for U660F: See page

.gif)

- for U760E: See page

.gif)

- for U760F: See page

.gif)

3. DRAIN TRANSFER OIL (for AWD)

.gif)

4. REMOVE FRONT WHEELS

5. REMOVE FRONT AXLE SHAFT NUT

|

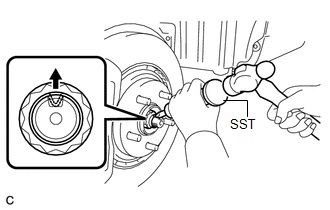

(a) Using SST and a hammer, release the staked part of the front axle shaft nut. SST: 09930-00010 NOTICE: Loosen the staked part of the nut completely, otherwise the threads of the drive shaft may be damaged. |

|

(b) While applying the brakes, remove the front axle shaft nut.

6. SEPARATE FRONT STABILIZER LINK ASSEMBLY

.gif)

7. SEPARATE FRONT SPEED SENSOR

|

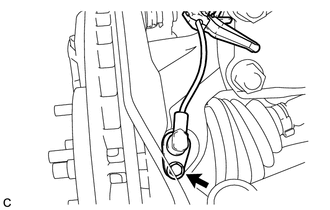

(a) Remove the bolt and separate the front speed sensor from the steering knuckle. |

|

|

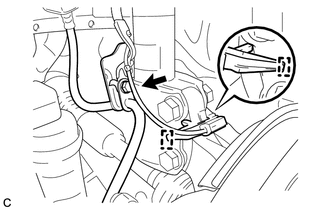

(b) Remove the bolt and clamp, and separate the front speed sensor and front flexible hose. |

|

8. SEPARATE TIE ROD ASSEMBLY

.gif)

9. SEPARATE FRONT LOWER SUSPENSION ARM

.gif)

10. SEPARATE FRONT AXLE ASSEMBLY

.gif)

11. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

|

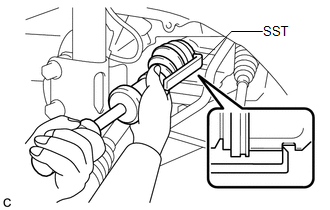

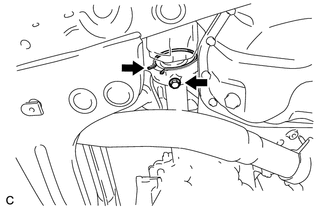

(a) Using SST, remove the front drive shaft assembly LH. SST: 09520-01010 SST: 09520-24010 09520-32040 NOTICE:

|

|

12. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH (for 2WD)

|

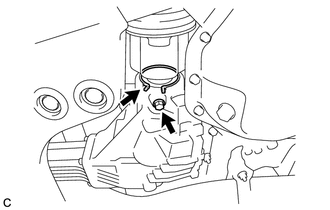

(a) Remove the bearing bracket hole snap ring from the drive shaft bearing bracket. |

|

(b) Remove the bolt and front drive shaft assembly RH from the drive shaft bearing bracket.

NOTICE:

Do not damage the boot or oil seal.

13. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH (for AWD)

|

(a) Remove the bearing bracket hole snap ring from the drive shaft bearing bracket. |

|

(b) Remove the bolt and front drive shaft assembly RH from the drive shaft bearing bracket.

NOTICE:

Do not damage the boot or oil seal.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE FRONT DRIVE SHAFT HOLE SNAP RING (for LH Side)

(a) Using a screwdriver, remove the front drive shaft hole snap ring.

...

Other materials about Toyota Venza:

Precaution

PRECAUTION

NOTICE:

When disconnecting the cable from the negative (-) battery terminal, initialize

the following system after the cable is reconnected.

System Name

See Procedure

Back Door Closer System

...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE TRANSMISSION WIRE

2. REMOVE ATF TEMPERATURE SENSOR ASSEMBLY

(a) Remove the 4 bolts, ATF temperature sensor assembly and clamp from

the valve body assembly.

Text in Illustration

*1

...

Driver Side Door Entry Lock Function does not Operate

DESCRIPTION

If the driver door entry unlock function operates normally, but its entry lock

function does not, this means that the request code from the driver door is being

output normally. In this case, a malfunction in the lock sensor circuit (from the ...

0.115