Toyota Venza: Disassembly

DISASSEMBLY

PROCEDURE

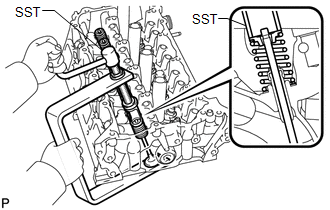

1. REMOVE INTAKE VALVE

|

(a) Using SST and wooden blocks, compress the compression spring and remove the valve spring retainer locks. SST: 09202-70020 09202-00010 |

|

(b) Remove the retainer, compression spring and valve.

HINT:

Arrange the removed parts in the correct order.

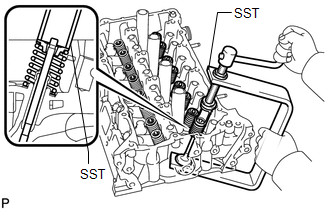

2. REMOVE EXHAUST VALVE

|

(a) Using SST and wooden blocks, compress the compression spring and remove the valve spring retainer locks. SST: 09202-70020 09202-00010 |

|

(b) Remove the retainer, compression spring and valve.

HINT:

Arrange the removed parts in the correct order.

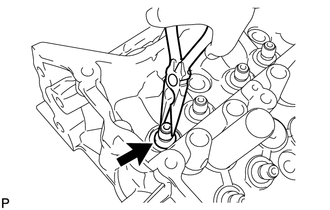

3. REMOVE VALVE STEM OIL SEAL

|

(a) Using needle-nose pliers, remove the oil seals. |

|

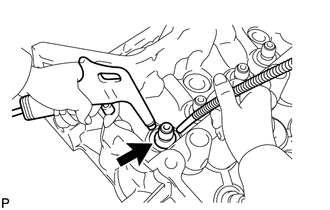

4. REMOVE VALVE SPRING SEAT

|

(a) Using compressed air and a Magnet Hand, remove the valve spring seat by blowing air onto it. |

|

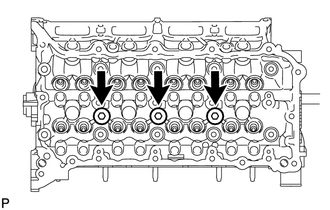

5. REMOVE NO. 1 STRAIGHT SCREW PLUG

NOTICE:

If water leaks from the No. 1 screw plug or the plug is corroded, replace it.

(a) Using a 10 mm hexagon wrench, remove the 3 screw plugs and 3 gaskets.

6. REMOVE NO. 2 STRAIGHT SCREW PLUG

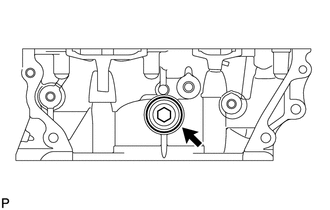

NOTICE:

If water leaks from the No. 2 screw plug or the plug is corroded, replace it.

(a) Using a 14 mm hexagon wrench, remove the screw plug and gasket.

7. REMOVE STUD BOLT

NOTICE:

If a stud bolt is deformed or its threads are damaged, replace it.

Components

Components

COMPONENTS

ILLUSTRATION

...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT CYLINDER HEAD SUB-ASSEMBLY

(a) Using a precision straightedge and feeler gauge, measure the warpage of the

contact surfaces where the cylinder head contacts the cy ...

Other materials about Toyota Venza:

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

Audio and Visual System

DTC Code

Detection Item

See page

B1532

LVDS Signal Malfunction (from Extension Module)

B1551

HD Radio ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT GENERATOR PULLEY WITH CLUTCH

(a) Hold the center of the pulley, and confirm that the outer ring turns

counterclockwise and does not turn clockwise.

Text in Illustration

*1

...

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR WHEELS

2. REMOVE CENTER EXHAUST PIPE ASSEMBLY

(a) Remove the center exhaust pipe assembly.

HINT:

Refer to the instructions for Removal of the exhaust pipe (See page

for 2GR-FE,

for 1AR-FE).

3. REMOVE LOWER NO. 1 EXH ...

2.8143