Toyota Venza: Differential Oil Seal

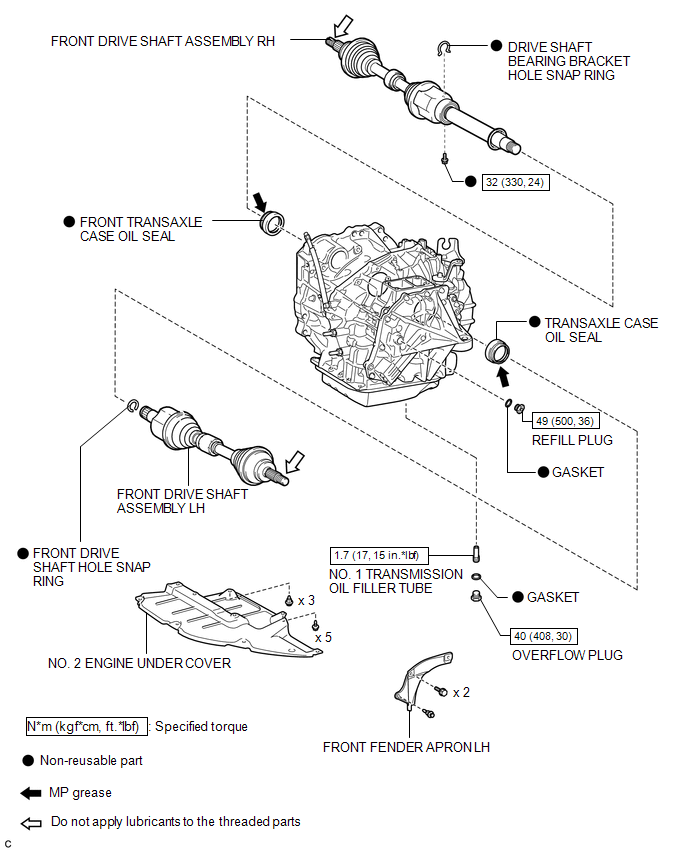

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. DRAIN AUTOMATIC TRANSAXLE FLUID

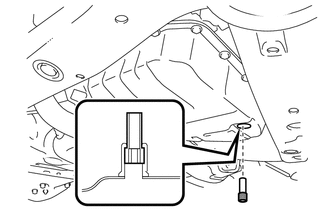

(a) Remove the No. 2 engine under cover and front fender apron LH.

|

(b) Using a 6 mm socket hexagon wrench, remove the overflow plug and gasket from the automatic transaxle. |

|

|

(c) Remove the refill plug and gasket from the automatic transaxle. |

|

|

(d) Using a 6 mm socket hexagon wrench, remove the No. 1 transmission oil filler tube from the automatic transaxle. |

|

(e) Drain automatic transaxle fluid from the automatic transaxle.

|

(f) Using a 6 mm socket hexagon wrench, install the No. 1 transmission oil filler tube to the automatic transaxle. Torque: 1.7 N·m {17 kgf·cm, 15 in·lbf} |

|

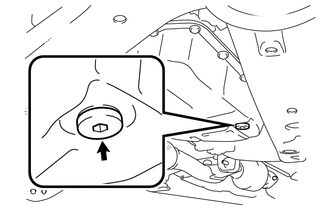

|

(g) Using a 6 mm socket hexagon wrench, install a new gasket and the overflow plug to the automatic transaxle. Torque: 40 N·m {408 kgf·cm, 30 ft·lbf} |

|

|

(h) Install a new gasket and the refill plug to the automatic transaxle. Torque: 49 N·m {500 kgf·cm, 36 ft·lbf} |

|

2. REMOVE FRONT DRIVE SHAFT ASSEMBLY

HINT:

See page .gif)

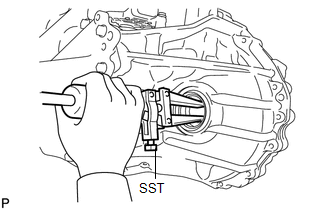

3. REMOVE TRANSAXLE CASE OIL SEAL

|

(a) Using SST, tap out the transaxle case oil seal. SST: 09308-00010 |

|

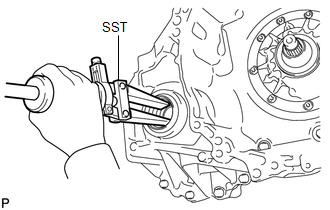

4. REMOVE FRONT TRANSAXLE CASE OIL SEAL

|

(a) Using SST, tap out the front transaxle case oil seal. SST: 09308-00010 |

|

5. INSTALL TRANSAXLE CASE OIL SEAL

|

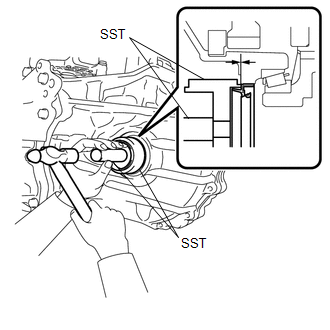

(a) Using SST and a hammer, tap in a new transaxle case oil seal. SST: 09316-10010 SST: 09950-70010 09951-07100 Oil seal driven in depth: -0.5 to 0.5 mm (-0.0197 to 0.0197 in.) NOTICE: Check that the oil seal is installed in the correct direction. |

|

(b) Coat the lip of the transaxle case oil seal with MP grease.

6. INSTALL FRONT TRANSAXLE CASE OIL SEAL

|

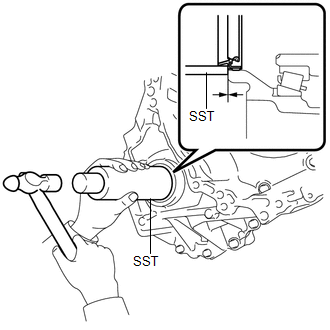

(a) Using SST and a hammer, tap in a new front transaxle case oil seal. SST: 09316-60011 09316-00011 Oil seal driven in depth: -0.5 to 0.5 mm (-0.0197 to 0.0197 in.) NOTICE: Check that the oil seal is installed in the correct direction. |

|

(b) Coat the lip of the front transaxle case oil seal with MP grease.

7. INSTALL FRONT DRIVE SHAFT ASSEMBLY

HINT:

See page .gif)

8. ADD AUTOMATIC TRANSAXLE FLUID

HINT:

See page .gif)

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FRONT DIFFERENTIAL CASE REAR TAPERED ROLLER BEARING

(a) Using SST and a press, install a new front differential case rear

tapered roller bearing (inne ...

Oil Pump

Oil Pump

...

Other materials about Toyota Venza:

Mass Air Flow Meter

Components

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

NOTICE:

Perform the mass air flow meter inspection according to the procedure

below.

Only replace the mass air flow meter when t ...

Speaker Output Short (B15C3)

DESCRIPTION

This DTC is stored when a malfunction occurs in the speakers.

DTC No.

DTC Detection Condition

Trouble Area

B15C3

A short is detected in the speaker output circuit.

...

Dtc Check / Clear

DTC CHECK / CLEAR

1. CHECK DTC

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Navigation System / Trouble

Codes.

(e) Check for DTCs (See page ).

...

0.1604

.png)

.png)