Toyota Venza: Diagnosis System

DIAGNOSIS SYSTEM

1. CHECK BATTERY VOLTAGE

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge the battery before proceeding to the next step.

2. CHECK DLC3

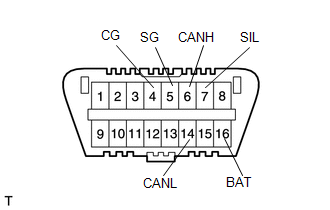

(a) The ECU uses ISO 15765-4 for communication. The terminal arrangement of the DLC3 complies with SAE J1962 and matches the ISO 15765-4 format.

|

Symbol (Terminal No.) |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|

|

SIL (7) - SG (5) |

Bus "+" line |

During transmission |

Pulse generation |

|

CG (4) - Body ground |

Chassis ground |

Always |

Below 1 Ω |

|

SG (5) - Body ground |

Signal ground |

Always |

Below 1 Ω |

|

BAT (16) - Body ground |

Battery positive |

Always |

11 to 14 V |

|

CANH (6) - CANL (14) |

CAN bus line |

Ignition switch off* |

54 to 69 Ω |

|

CANH (6) - CG (4) |

HIGH-level CAN bus line |

Ignition switch off* |

200 Ω or higher |

|

CANL (14) - CG (4) |

LOW-level CAN bus line |

Ignition switch off* |

200 Ω or higher |

|

CANH (6) - BAT (16) |

HIGH-level CAN bus line |

Ignition switch off* |

6 kΩ or higher |

|

CANL (14) - BAT (16) |

LOW-level CAN bus line |

Ignition switch off* |

6 kΩ or higher |

NOTICE:

*: Before measuring the resistance, leave the vehicle as is for at least 1 minute and do not operate the ignition switch or any other switches or the doors.

(b) If the result is not as specified, the DLC3 may have a malfunction. Repair or replace the harness and connector.

HINT:

Connect the Techstream cable to the DLC3, turn the ignition switch on (IG) and attempt to use the Techstream. If the display indicates that a communication error has occurred, there is a problem either with the vehicle or with the Techstream.

- If communication is normal when the Techstream is connected to another vehicle, inspect the DLC3 of the original vehicle.

- If communication is still not possible when the Techstream is connected to another vehicle, the problem may be in the Techstream itself. Consult the Service Department listed in the Techstream instruction manual.

3. DIAGNOSIS SYSTEM

(a) Warning light

.png)

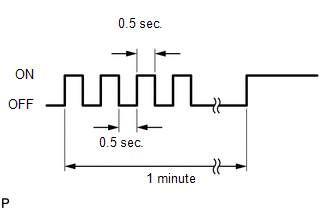

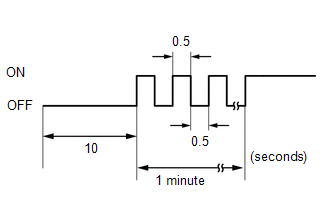

(1) When there is a problem with the tire pressure warning system, the tire pressure warning light blinks at 0.5 second intervals and comes on after 1 minute.

NOTICE:

When the malfunction has been corrected, the tire pressure warning light does not come on.

(b) DTCs (Normal mode)

(1) DTCs are memorized in the tire pressure warning ECU and read by the blinks

of the tire pressure warning light or by using the Techstream (See page

.gif) ).

).

(c) Test mode

(1) By switching from normal mode into test mode (input signal check), you can

inspect the tire pressure warning antenna and receiver, each tire pressure warning

valve and transmitter, engine speed signal and vehicle speed sensor (See page

.gif) ).

).

4. CHECK TIRE PRESSURE WARNING LIGHT

(a) Turn the ignition switch to ON.

.png)

(b) Check that the tire pressure warning light comes on for 3 seconds.

If the warning check result is not normal, proceed to the troubleshooting for

the tire pressure warning light circuit (See page

.gif) ).

).

5. TIRE PRESSURE WARNING LIGHT CHART

HINT:

The table below indicates the tire pressure warning system status according to the tire pressure warning light after the ignition switch is turned to ON.

|

System Status |

Immediately after turning the ignition switch to ON |

Always |

|||||

|---|---|---|---|---|---|---|---|

|

Warning light output pattern |

|||||||

|

Comes on for 3 sec. |

Goes off |

Comes on |

Blinks for 1 minute and then illuminates*1 |

Blinks*2 |

Blinks*3 |

Outputs DTC |

|

|

Normal |

○ |

○ |

- |

- |

- |

- |

- |

|

Low tire pressure |

○ |

- |

○ |

- |

- |

- |

- |

|

System fail |

○ |

- |

- |

○ |

- |

- |

- |

|

Test mode |

○ |

- |

- |

- |

○ |

- |

- |

|

ECU connector poorly connected |

- |

- |

- |

○*4 |

- |

- |

- |

|

TC ground (DTC is output) |

○ |

- |

- |

- |

- |

- |

○ |

|

TC ground (DTC is not output) |

○ |

- |

- |

- |

- |

○ |

- |

- *1: Comes on and goes off repeatedly at 0.5 second intervals, and stays

on after 1 minute.

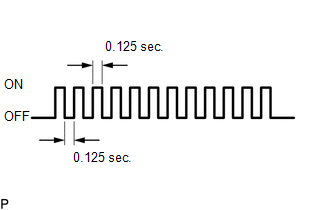

- *2: Comes on and goes off repeatedly at 0.125 second intervals.

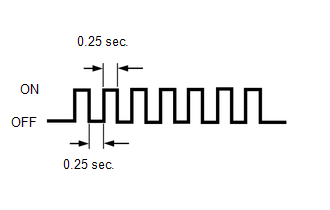

- *3: Comes on and goes off repeatedly at 0.25 second intervals.

- *4: If it is determined that there is a short circuit, the light will

remain off for 10 seconds. It will then blink at 0.5 second intervals and

stay on after 1 minute.

Test Mode Procedure

Test Mode Procedure

TEST MODE PROCEDURE

1. ENTER TEST MODE (SIGNAL CHECK MODE)

(a) Turn the ignition switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Check that the tire pr ...

Terminals Of Ecu

Terminals Of Ecu

TERMINALS OF ECU

1. CHECK TIRE PRESSURE WARNING ECU

HINT:

Inspect the connectors from the back side while the connectors are connected.

(a) Disconnect the L14 tire pressure warning antenna and r ...

Other materials about Toyota Venza:

Trailer towing

Your vehicle is designed primarily as a passenger-and-load-carrying vehicle.

Towing a trailer can have an adverse impact on handling, performance, braking, durability,

and fuel consumption. For your safety and the safety of others, you must not overload

...

Engine Switch Illumination Circuit

DESCRIPTION

The illuminated entry system controls the engine switch illumination.

WIRING DIAGRAM

PROCEDURE

1.

PERFORM ACTIVE TEST USING TECHSTREAM

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to O ...

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the fuel pump assembly (See

page ).

PROCEDURE

1. DISCHARGE FUEL SYSTEM PRESSURE

(a) Discharge fuel system pressure (See page

).

2. DISCONNECT CABLE FR ...

0.1392