Toyota Venza: Reassembly

REASSEMBLY

PROCEDURE

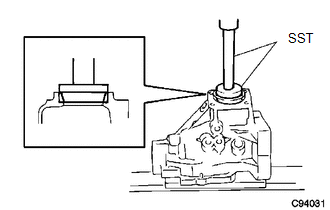

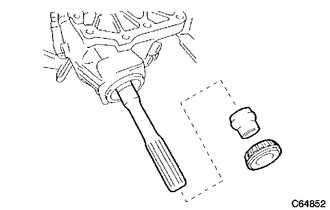

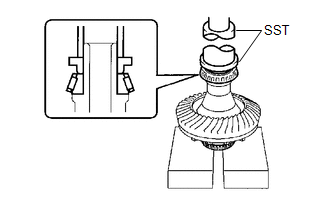

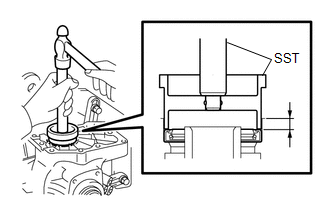

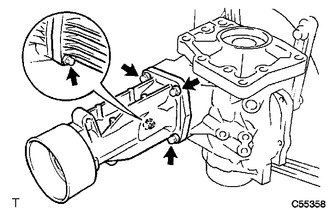

1. INSTALL TRANSFER DRIVEN PINION REAR BEARING

|

(a) Using SST and a press, press the transfer driven pinion rear bearing (outer race) to the case. SST: 09950-60010 09951-00620 SST: 09950-70010 09951-07150 NOTICE: Keep the transfer case horizontal using wooden blocks, etc. |

|

(b) Apply gear oil to the transfer driven pinion rear bearing (outer race).

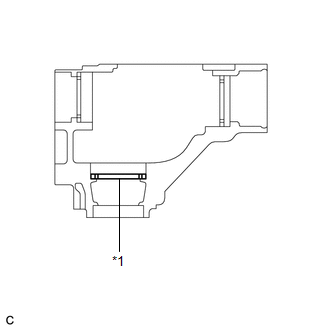

2. INSTALL TRANSFER OUTPUT SHAFT WASHER

(a) Install the transfer output shaft washer to the transfer case.

HINT:

Install the same transfer output shaft washer as the one removed.

(b) Apply gear oil to the transfer output shaft washer.

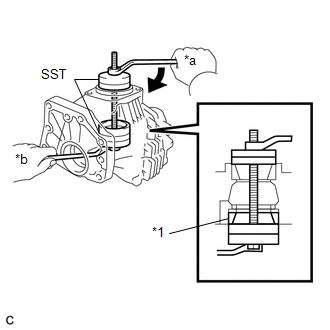

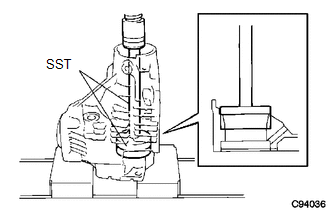

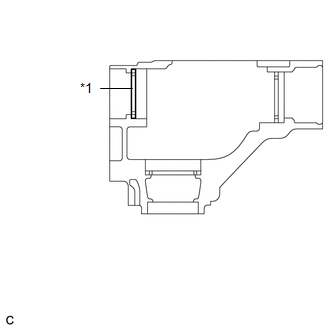

3. INSTALL TRANSFER DRIVEN PINION FRONT BEARING

|

(a) Apply gear oil to the inner surface of the transfer case. |

|

(b) Using SST, install the transfer driven pinion front bearing (outer race) to the transfer case.

SST: 09950-60010

09951-00610

09951-00620

09951-00650

SST: 09950-60020

09951-00680

Text in Illustration|

*1 |

Transfer Driven Pinion Front Bearing (Outer Race) |

|

*a |

Turn |

|

*b |

Hold |

|

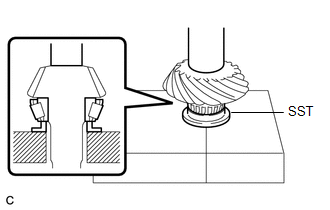

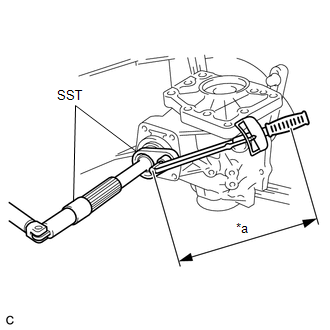

(c) Using SST and a press, press the transfer driven pinion front bearing (inner race) into the driven pinion. SST: 09506-30012 |

|

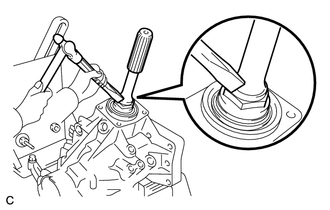

4. INSTALL DRIVEN PINION

|

(a) Install the driven pinion to the transfer case. |

|

|

(b) Install a new transfer pinion bearing spacer and the transfer driven pinion rear bearing (inner race) to the driven pinion. HINT: Install the transfer pinion bearing spacer with the larger inner diameter facing forward as shown in the illustration. |

|

|

(c) Using SST, install a new gear nut. SST: 09326-20011 SST: 09556-16030 Torque: Specified tightening torque : 270-420 N·m {2753-4283 kgf·cm, 199-310 ft·lbf} Text in Illustration

NOTICE: Do not stake the gear nut until the final preload, tooth contact and backlash adjustments are completed. HINT:

|

|

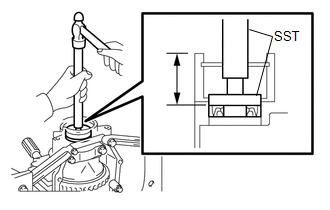

5. ADJUST DRIVEN PINION PRELOAD

|

(a) Using SST and a torque wrench, measure the driven pinion preload. SST: 09326-20011 Text in Illustration

Specified Preload (at Starting):

NOTICE:

HINT:

|

|

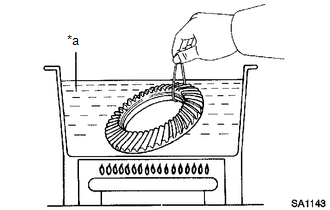

6. INSTALL RING GEAR

(a) Clean the contact surfaces of the ring gear and transfer ring gear mounting case.

|

(b) Heat the ring gear in boiling water. Text in Illustration

|

|

(c) Carefully remove the ring gear from the boiling water.

(d) Secure the transfer ring gear mounting case in a vise using aluminum plates.

NOTICE:

Be careful not to damage the transfer ring gear mounting case in the vise.

|

(e) After the moisture on the ring gear has completely evaporated, quickly align the matchmarks and set the ring gear to the transfer ring gear mounting case. Text in Illustration

|

|

(f) Apply adhesive to the 12 new bolts.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

(g) Install the 12 bolts.

Torque:

99 N·m {1005 kgf·cm, 73 ft·lbf}

NOTICE:

- Tighten the bolts evenly in a diagonal pattern using several steps.

- Tighten the bolts after the ring gear has cooled down sufficiently.

- In order to ensure proper sealing of the bolts, apply adhesive to the bolts and install them within 10 minutes of adhesive application.

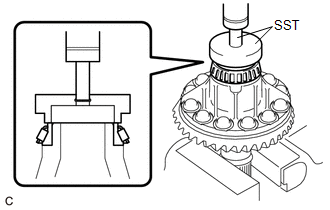

7. INSTALL RING GEAR MOUNTING CASE BEARING

|

(a) Using SST and a press, press the ring gear mounting case bearing (inner race) to the transfer ring gear mounting case. SST: 09387-00010 SST: 09950-70010 09951-07100 |

|

(b) Install the ring gear mounting case bearing (outer race) to the transfer ring gear mounting case.

(c) Apply gear oil to the ring gear mounting case bearing.

|

(d) Using SST and a press, press the ring gear mounting case bearing (inner race) to the transfer ring gear mounting case. SST: 09223-00010 SST: 09726-40010 |

|

(e) Install the ring gear mounting case plate washer to the case.

HINT:

If replacing the case plate washer, use one with the same thickness as the one removed.

|

(f) Using SST and a press, press the ring gear mounting case bearing (outer race) into the transfer case. SST: 09950-60010 09951-00680 SST: 09950-70010 09951-07200 |

|

(g) Apply gear oil to the ring gear mounting case bearing.

8. INSTALL TRANSFER RING GEAR MOUNTING CASE

|

(a) Apply gear oil to the transfer ring gear mounting case. |

|

(b) Install the transfer ring gear mounting case to the transfer case.

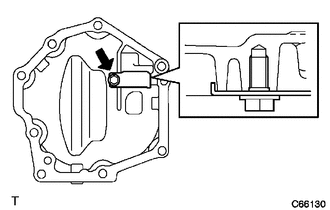

9. INSTALL NO. 1 TRANSFER OUTPUT SHAFT SPACER

|

(a) Align the cutout on the No. 1 transfer output shaft spacer with the transfer case hole to install it as shown in the illustration. Text in Illustration

|

|

10. INSTALL NO. 2 TRANSFER RING GEAR MOUNTING CASE WASHER

|

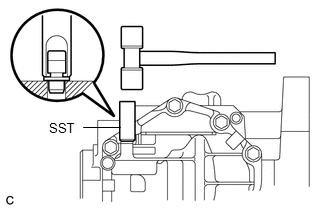

(a) Using a brass bar and a hammer, install the No. 2 transfer ring gear mounting case washer. HINT: Use a No. 2 transfer ring gear mounting case washer with the same thickness as the one removed. |

|

11. INSTALL BEARING CAP

|

(a) Install the bearing cap with the 2 bolts. Torque: 63 N·m {644 kgf·cm, 47 ft·lbf} |

|

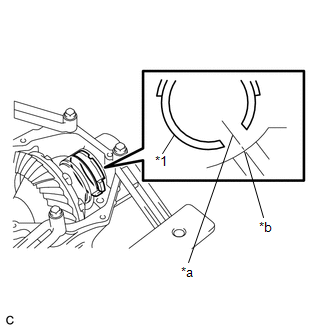

12. INSPECT RING GEAR BACKLASH

|

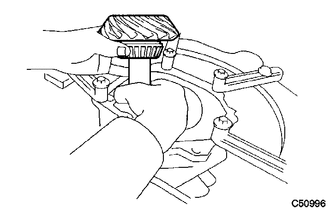

(a) Set a dial indicator perpendicular to a ring gear tooth tip. Secure the driven pinion in place and move the ring gear back and forth to measure the backlash. Backlash: 0.14 to 0.25 mm (0.00551 to 0.00984 in.) NOTICE: Check at least 3 positions on the circumference of the ring gear. |

|

|

(b) If the backlash is outside the specified range, select a ring gear mounting case washer from the table and install it to meet the specified range. Text in Illustration

|

|

13. INSPECT TOOTH CONTACT BETWEEN RING GEAR AND DRIVEN PINION

|

(a) Coat 3 or 4 teeth at 4 different positions on the ring gear with Prussian blue. |

|

(b) Rotate the ring gear 10 times or more.

(c) Rotate the ring gear to inspect the tooth contact pattern.

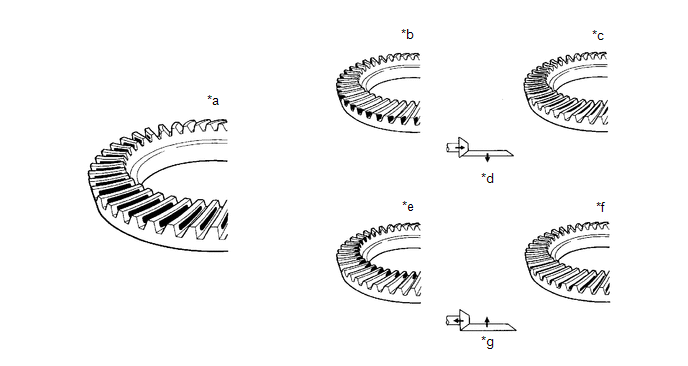

Text in Illustration

Text in Illustration

|

*a |

Proper Contact |

*b |

Heel Contact |

|

*c |

Face Contact |

*d |

Select a washer that will bring the driven pinion closer to the ring gear |

|

*e |

Toe Contact |

*f |

Flank Contact |

|

*g |

Select a washer that will shift the driven pinion away from the ring gear |

- |

- |

|

(d) If the tooth contact pattern is not correct, select a new transfer output shaft washer that is thicker or thinner as necessary and recheck. Text in Illustration

NOTICE: When the washer thickness is changed, readjust the backlash (See page

|

|

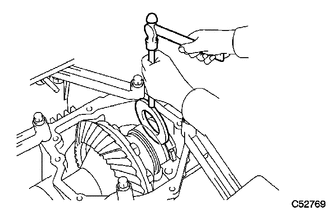

14. INSPECT AND ADJUST TOTAL PRELOAD

(a) Using SST and a torque wrench, measure the total preload.

SST: 09326-20011

Text in Illustration

Text in Illustration

|

*a |

Torque Wrench Fulcrum Length |

Specified Total Preload (at Starting):

|

Item |

Preload |

|---|---|

|

New bearing |

0.48 to 0.70 N*m (5 to 7 kgf*cm, 5 to 6 in.*lbf) + Driven pinion preload |

|

Reused bearing |

0.35 to 0.53 N*m (4 to 5 kgf*cm, 4 to 4.6 in.*lbf) + Driven pinion preload |

NOTICE:

Turn the driven pinion counterclockwise and clockwise several times.

HINT:

- Calculate the torque wrench reading when changing the fulcrum length

of the torque wrench (See page

.gif) ).

).

- When using SST (fulcrum length of 50 mm (1.97 in.)) + torque wrench

(fulcrum length of 130 mm (5.12 ft.)):

Total Preload (at Starting):

Item

Preload

New bearing

0.35 to 0.50 N*m (4 to 5 kgf*cm, 4 to 4.4 in.*lbf) + Driven pinion preload

Reused bearing

0.25 to 0.38 N*m (3 to 3.8 kgf*cm, 3 to 3.3 in.*lbf) + Driven pinion preload

If the preload is outside the specified range, replace the No. 2 transfer ring gear mounting case washer with one that is thicker or thinner as necessary and recheck.

.png) Text in Illustration

Text in Illustration

|

*1 |

No. 2 Transfer Ring Gear Mounting Case Washer |

|

Mark |

Thickness (mm (in.)) |

Mark |

Thickness (mm (in.)) |

|---|---|---|---|

|

G7 |

2.47 (0.0972) |

M7 |

3.47 (0.1366) |

|

G8 |

2.49 (0.0980) |

M8 |

3.49 (0.1374) |

|

G9 |

2.51 (0.0988) |

M9 |

3.51 (0.1382) |

|

H0 |

2.53 (0.0996) |

N0 |

3.53 (0.1390) |

|

H1 |

2.55 (0.1004) |

N1 |

3.55 (0.1398) |

|

H2 |

2.57 (0.1012) |

N2 |

3.57 (0.1406) |

|

H3 |

2.59 (0.1020) |

N3 |

3.59 (0.1413) |

|

H4 |

2.61 (0.1028) |

N4 |

3.61 (0.1421) |

|

H5 |

2.63 (0.1035) |

N5 |

3.63 (0.1429) |

|

H6 |

2.65 (0.1043) |

N6 |

3.65 (0.1437) |

|

H7 |

2.67 (0.1051) |

N7 |

3.67 (0.1445) |

|

H8 |

2.69 (0.1059) |

N8 |

3.69 (0.1453) |

|

H9 |

2.71 (0.1067) |

N9 |

3.71 (0.1461) |

|

J0 |

2.73 (0.1075) |

P0 |

3.73 (0.1469) |

|

J1 |

2.75 (0.1083) |

P1 |

3.75 (0.1476) |

|

J2 |

2.77 (0.1091) |

P2 |

3.77 (0.1484) |

|

J3 |

2.79 (0.1098) |

P3 |

3.79 (0.1492) |

|

J4 |

2.81 (0.1106) |

P4 |

3.81 (0.1500) |

|

J5 |

2.83 (0.1114) |

P5 |

3.83 (0.1508) |

|

J6 |

2.85 (0.1122) |

P6 |

3.85 (0.1516) |

|

J7 |

2.87 (0.1130) |

P7 |

3.87 (0.1524) |

|

J8 |

2.89 (0.1138) |

P8 |

3.89 (0.1531) |

|

J9 |

2.91 (0.1146) |

P9 |

3.91 (0.1539) |

|

K0 |

2.93 (0.1154) |

Q0 |

3.93 (0.1547) |

|

K1 |

2.95 (0.1161) |

Q1 |

3.95 (0.1555) |

|

K2 |

2.97 (0.1169) |

Q2 |

3.97 (0.1563) |

|

K3 |

2.99 (0.1177) |

Q3 |

3.99 (0.1571) |

|

K4 |

3.01 (0.1185) |

Q4 |

4.01 (0.1579) |

|

K5 |

3.03 (0.1193) |

Q5 |

4.03 (0.1587) |

|

K6 |

3.05 (0.1201) |

Q6 |

4.05 (0.1594) |

|

K7 |

3.07 (0.1209) |

Q7 |

4.07 (0.1602) |

|

K8 |

3.09 (0.1217) |

Q8 |

4.09 (0.1610) |

|

K9 |

3.11 (0.1224) |

Q9 |

4.11 (0.1618) |

|

L0 |

3.13 (0.1232) |

R0 |

4.13 (0.1626) |

|

L1 |

3.15 (0.1240) |

R1 |

4.15 (0.1634) |

|

L2 |

3.17 (0.1248) |

R2 |

4.17 (0.1642) |

|

L3 |

3.19 (0.1256) |

R3 |

4.19 (0.1650) |

|

L4 |

3.21 (0.1264) |

R4 |

4.21 (0.1657) |

|

L5 |

3.23 (0.1272) |

R5 |

4.23 (0.1665) |

|

L6 |

3.25 (0.1280) |

R6 |

4.25 (0.1673) |

|

L7 |

3.27 (0.1287) |

R7 |

4.27 (0.1681) |

|

L8 |

3.29 (0.1295) |

R8 |

4.29 (0.1689) |

|

L9 |

3.31 (0.1303) |

R9 |

4.31 (0.1697) |

|

M0 |

3.33 (0.1311) |

S0 |

4.33 (0.1705) |

|

M1 |

3.35 (0.1319) |

S1 |

4.35 (0.1713) |

|

M2 |

3.37 (0.1327) |

S2 |

4.37 (0.1720) |

|

M3 |

3.39 (0.1335) |

S3 |

4.39 (0.1728) |

|

M4 |

3.41 (0.1343) |

S4 |

4.41 (0.1736) |

|

M5 |

3.43 (0.1350) |

S5 |

4.43 (0.1744) |

|

M6 |

3.45 (0.1358) |

S6 |

4.45 (0.1752) |

|

(b) Using a chisel and a hammer, stake the gear nut. |

|

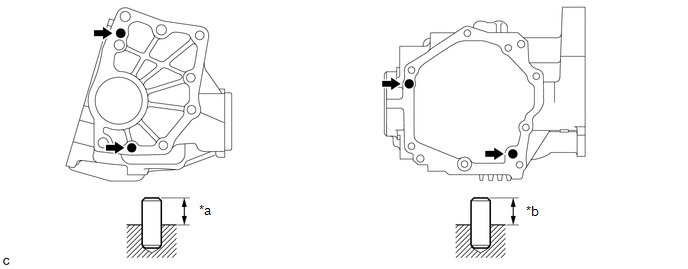

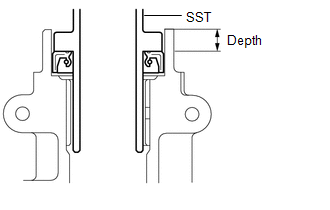

15. INSTALL TRANSFER CASE FRONT OIL SEAL (for RH Side)

|

(a) Using SST and a hammer, drive a new transfer case front oil seal into the case until it reaches the position shown in the illustration. SST: 09950-60010 09951-00350 09951-00580 09952-06010 SST: 09950-70010 09951-07150 Drive in depth: 33.5 to 34.5 mm (1.319 to 1.358 in.) NOTICE: Make sure that the transfer case front oil seal is not tilted. |

|

(b) Apply a small amount of MP grease to the lip of the transfer case front oil seal.

16. INSTALL TRANSFER CASE FRONT OIL SEAL

|

(a) Using SST and a hammer, drive a new transfer case front oil seal into the transfer case until it reaches the position in the illustration. SST: 09608-10010 SST: 09950-70010 09951-07150 Drive in depth: 9.5 to 10.5 mm (0.374 to 0.413 in.) |

|

(b) Apply a small amount of MP grease to the lip of the transfer case front oil seal.

17. INSTALL TRANSFER CASE REAR OIL SEAL

|

(a) Using SST and a hammer, drive a new transfer case rear oil seal into the extension housing until it reaches the position shown in the illustration. SST: 09325-20010 Drive in depth: 9.8 to 10.6 mm (0.386 to 0.417 in.) |

|

(b) Apply a small amount of MP grease to the lip of the transfer case rear oil seal.

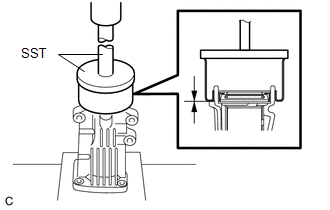

18. INSTALL TRANSFER EXTENSION HOUSING DUST DEFLECTOR

|

(a) Using SST and a press, press in a new transfer extension housing dust deflector until it contacts the installation surface as shown in the illustration. SST: 09950-60020 09951-01030 SST: 09950-70010 09951-07150 |

|

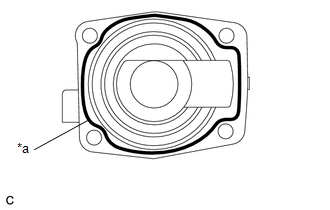

19. INSTALL TRANSFER EXTENSION HOUSING SUB-ASSEMBLY

|

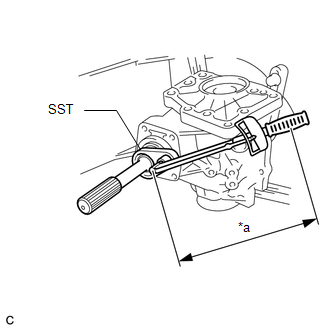

(a) Remove any FIPG material and be careful not to drop oil on the contact surfaces of the transfer extension housing sub-assembly and the transfer case. Text in Illustration

|

|

(b) Degrease the surfaces with a non-residue solvent.

(c) Apply FIPG to the transfer extension housing sub-assembly.

FIPG:

Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

|

(d) Install the transfer extension housing sub-assembly with the 4 bolts to the transfer case. Torque: 26 N·m {260 kgf·cm, 19 ft·lbf} NOTICE: Assemble the transfer extension housing sub-assembly within 10 minutes of FIPG application. |

|

20. SEPARATE TRANSFER ASSEMBLY

(a) Remove the transfer assembly from the overhaul attachment.

21. INSTALL TRANSFER CASE STRAIGHT PIN

(a) Using a plastic hammer, drive the 4 transfer case straight pins into the transfer case positions shown in the illustration.

Text in Illustration

Text in Illustration

|

*a |

10.8 to 11.8 mm (0.425 to 0.465 in.) |

*b |

5.7 to 6.7 mm (0.224 to 0.264 in.) |

22. INSTALL TRANSFER DYNAMIC DAMPER (for 1AR-FE)

|

(a) Install the transfer dynamic damper with the 3 bolts to the transfer extension housing sub-assembly. Torque: 26 N·m {260 kgf·cm, 19 ft·lbf} |

|

23. INSTALL TRANSFER CASE BREATHER PLUG

|

(a) Using SST and a hammer, tap in a new transfer case breather plug. SST: 09820-00031 |

|

24. INSTALL BREATHER OIL DEFLECTOR

|

(a) Install the breather oil deflector with the bolt. Torque: 6.5 N·m {66 kgf·cm, 58 in·lbf} |

|

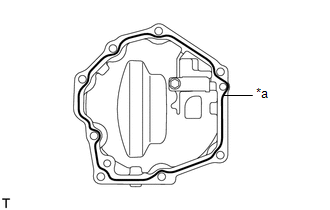

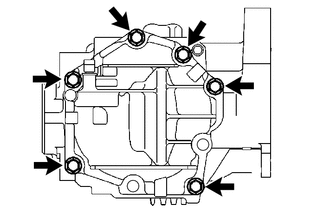

25. INSTALL NO. 1 TRANSFER CASE COVER

|

(a) Remove any FIPG material and be careful not to drop oil on the contact surfaces of the No. 1 transfer case cover and the transfer case. Text in Illustration

|

|

(b) Degrease the surfaces with a non-residue solvent.

(c) Apply FIPG to the No. 1 transfer case cover.

FIPG:

Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

|

(d) Install the No. 1 transfer case cover with the 6 bolts. Torque: 20 N·m {200 kgf·cm, 14 ft·lbf} NOTICE:

|

|

|

(e) Install the No. 1 transfer case cover with 2 new bolts. Torque: 20 N·m {200 kgf·cm, 14 ft·lbf} |

|

26. INSTALL TRANSFER DRAIN PLUG

|

(a) Install a new gasket to the transfer drain plug. |

|

(b) Install the transfer drain plug to the transfer assembly.

Torque:

49 N·m {500 kgf·cm, 36 ft·lbf}

27. INSTALL NO. 1 TRANSFER CASE PLUG

|

(a) Install a new gasket to the No. 1 transfer case plug. |

|

(b) Install the No. 1 transfer case plug to the transfer assembly.

Torque:

49 N·m {500 kgf·cm, 36 ft·lbf}

28. INSTALL NO. 2 TRANSFER CASE PLUG

|

(a) Install a new gasket to the No. 2 transfer case plug. |

|

(b) Install the No. 2 transfer case plug to the transfer assembly.

Torque:

49 N·m {500 kgf·cm, 36 ft·lbf}

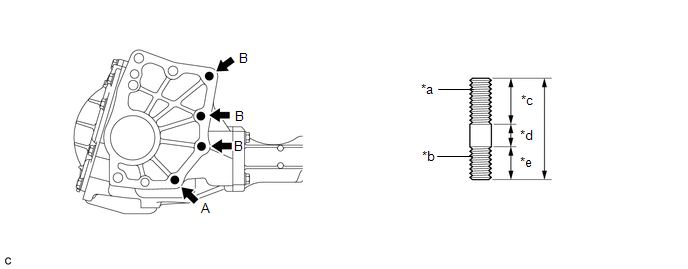

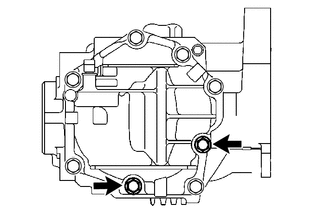

29. INSTALL TRANSFER AND TRANSAXLE SETTING STUD BOLT

(a) Install 4 new transfer and transaxle setting stud bolts to the transfer case positions shown in the illustration.

Torque:

Stud Bolt (A) :

39.2 N·m {400 kgf·cm, 29 ft·lbf}

Stud Bolt (B) :

25 N·m {255 kgf·cm, 18 ft·lbf}

HINT:

Install the shorter end of the stud bolts to the transfer assembly.

Text in Illustration

Text in Illustration

|

*a |

Transaxle Side |

*b |

Transfer Side |

|

*c |

30 mm (1.1811 in.) |

*d |

12 mm (0.4724 in.) |

|

*e |

22 mm (0.8661 in.) |

- |

- |

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT PRELOAD

(a) Using SST and a torque wrench, measure the preload of the backlash

between the driven pinion and ring gear.

SST: 09326-20011

Preload ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSFER ASSEMBLY

(a) Install the transfer assembly to the transaxle assembly with 2 new

bolts and the 6 nuts.

Torque:

69 N·m {700 kgf·cm, ...

Other materials about Toyota Venza:

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Precaution

PRECAUTION

1. PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

After the ignition switch is turned off, the navigation receiver assembly

records various types of memory and settings. As a result, after turning

the ig ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK STEERING EFFORT (TORQUE)

NOTICE:

Some of these service operations may affect the SRS airbags. Read the precautionary

notices concerning the SRS airbag system before servicing.

(a) Stop the vehicle on a level, pav ...

0.1306

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)