Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT PRELOAD

|

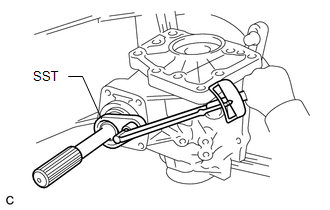

(a) Using SST and a torque wrench, measure the preload of the backlash between the driven pinion and ring gear. SST: 09326-20011 Preload (at Starting):

HINT:

|

|

(b) Using SST and a torque wrench, measure the total preload.

SST: 09326-20011

Preload (at Starting):

|

Item |

Preload |

|---|---|

|

without SST |

0.35 to 0.53 N*m (4 to 5 kgf*cm, 3 to 4 in.*lbf) + driven pinion preload |

|

with SST |

0.25 to 0.38 N*m (3 to 4 kgf*cm, 3 to 3.3 in.*lbf) + driven pinion preload |

HINT:

- Use a torque wrench with a fulcrum length of 130 mm (5.12 in.).

- Turn the driven pinion counterclockwise and clockwise several times.

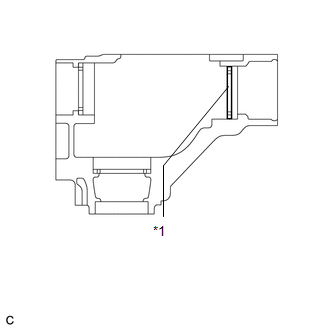

If the preload is outside the specified range, replace the No. 2 transfer ring gear mounting case washer with one that is thicker or thinner as necessary and recheck.

Text in Illustration|

*1 |

No. 2 Transfer Ring Gear Mounting Case Washer |

|

Mark |

Thickness |

Mark |

Thickness |

|---|---|---|---|

|

G7 |

2.47 (0.0972) |

M7 |

3.47 (0.1366) |

|

G8 |

2.49 (0.0980) |

M8 |

3.49 (0.1374) |

|

G9 |

2.51 (0.0988) |

M9 |

3.51 (0.1382) |

|

H0 |

2.53 (0.0996) |

N0 |

3.53 (0.1390) |

|

H1 |

2.55 (0.1004) |

N1 |

3.55 (0.1398) |

|

H2 |

2.57 (0.1012) |

N2 |

3.57 (0.1406) |

|

H3 |

2.59 (0.1020) |

N3 |

3.59 (0.1413) |

|

H4 |

2.61 (0.1028) |

N4 |

3.61 (0.1421) |

|

H5 |

2.63 (0.1035) |

N5 |

3.63 (0.1429) |

|

H6 |

2.65 (0.1043) |

N6 |

3.65 (0.1437) |

|

H7 |

2.67 (0.1051) |

N7 |

3.67 (0.1445) |

|

H8 |

2.69 (0.1059) |

N8 |

3.69 (0.1453) |

|

H9 |

2.71 (0.1067) |

N9 |

3.71 (0.1461) |

|

J0 |

2.73 (0.1075) |

P0 |

3.73 (0.1469) |

|

J1 |

2.75 (0.1083) |

P1 |

3.75 (0.1476) |

|

J2 |

2.77 (0.1091) |

P2 |

3.77 (0.1484) |

|

J3 |

2.79 (0.1098) |

P3 |

3.79 (0.1492) |

|

J4 |

2.81 (0.1106) |

P4 |

3.81 (0.1500) |

|

J5 |

2.83 (0.1114) |

P5 |

3.83 (0.1508) |

|

J6 |

2.85 (0.1122) |

P6 |

3.85 (0.1516) |

|

J7 |

2.87 (0.1130) |

P7 |

3.87 (0.1524) |

|

J8 |

2.89 (0.1138) |

P8 |

3.89 (0.1531) |

|

J9 |

2.91 (0.1146) |

P9 |

3.91 (0.1539) |

|

K0 |

2.93 (0.1154) |

Q0 |

3.93 (0.1547) |

|

K1 |

2.95 (0.1161) |

Q1 |

3.95 (0.1555) |

|

K2 |

2.97 (0.1169) |

Q2 |

3.97 (0.1563) |

|

K3 |

2.99 (0.1177) |

Q3 |

3.99 (0.1571) |

|

K4 |

3.01 (0.1185) |

Q4 |

4.01 (0.1579) |

|

K5 |

3.03 (0.1193) |

Q5 |

4.03 (0.1587) |

|

K6 |

3.05 (0.1201) |

Q6 |

4.05 (0.1594) |

|

K7 |

3.07 (0.1209) |

Q7 |

4.07 (0.1602) |

|

K8 |

3.09 (0.1217) |

Q8 |

4.09 (0.1610) |

|

K9 |

3.11 (0.1224) |

Q9 |

4.11 (0.1618) |

|

L0 |

3.13 (0.1232) |

R0 |

4.13 (0.1626) |

|

L1 |

3.15 (0.1240) |

R1 |

4.15 (0.1634) |

|

L2 |

3.17 (0.1248) |

R2 |

4.17 (0.1642) |

|

L3 |

3.19 (0.1256) |

R3 |

4.19 (0.1650) |

|

L4 |

3.21 (0.1264) |

R4 |

4.21 (0.1657) |

|

L5 |

3.23 (0.1272) |

R5 |

4.23 (0.1665) |

|

L6 |

3.25 (0.1280) |

R6 |

4.25 (0.1673) |

|

L7 |

3.27 (0.1287) |

R7 |

4.27 (0.1681) |

|

L8 |

3.29 (0.1295) |

R8 |

4.29 (0.1689) |

|

L9 |

3.31 (0.1303) |

R9 |

4.31 (0.1697) |

|

M0 |

3.33 (0.1311) |

S0 |

4.33 (0.1705) |

|

M1 |

3.35 (0.1319) |

S1 |

4.35 (0.1713) |

|

M2 |

3.37 (0.1327) |

S2 |

4.37 (0.1720) |

|

M3 |

3.39 (0.1335) |

S3 |

4.39 (0.1728) |

|

M4 |

3.41 (0.1343) |

S4 |

4.41 (0.1736) |

|

M5 |

3.43 (0.1350) |

S5 |

4.43 (0.1744) |

|

M6 |

3.45 (0.1358) |

S6 |

4.45 (0.1752) |

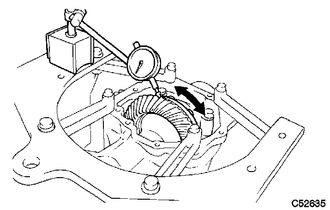

2. INSPECT RING GEAR BACKLASH

|

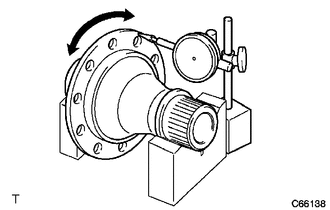

(a) Using a dial indicator, check the backlash of the ring gear. Backlash: 0.14 to 0.25 mm (0.00551 to 0.00984 in.) If the backlash is not within the specification, adjust the side bearing preload or repair as necessary. NOTICE: Check at least 3 positions on the circumference of the ring gear. |

|

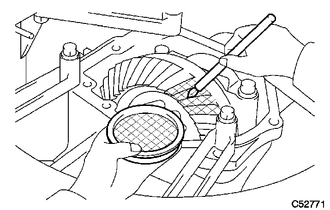

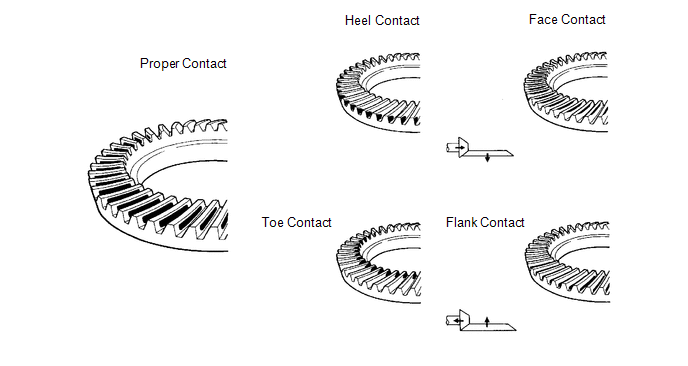

3. INSPECT TOOTH CONTACT BETWEEN RING GEAR AND DRIVE PINION

|

(a) Coat 3 or 4 teeth at 4 different positions on the ring gear with Prussian blue. |

|

(b) Turn the driven pinion to rotate the ring gear 10 times or more clockwise and 10 times or more counterclockwise.

(c) Rotate the ring gear to inspect the tooth pattern.

(d) If the tooth contact pattern is not correct, select a new transfer output shaft washer that is thicker or thinner as necessary and recheck.

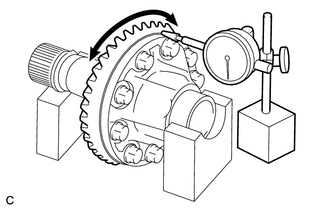

4. INSPECT RUNOUT OF RING GEAR

|

(a) Place the transfer ring gear mounting case on the V-blocks. |

|

(b) Using a dial indicator, check the runout of the ring gear.

Maximum runout:

0.06 mm (0.00236 in.)

HINT:

If the runout is more than maximum, replace the ring gear with a new one.

5. INSPECT TRANSFER RING GEAR MOUNTING CASE

|

(a) Place the transfer ring gear mounting case on the V-blocks. |

|

(b) Using a dial indicator, check the runout of the transfer ring gear mounting case.

Maximum runout:

0.04 mm (0.00157 in.)

HINT:

If the runout is more than maximum, replace the transfer ring gear mounting case with a new one.

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE TRANSFER AND TRANSAXLE SETTING STUD BOLT

(a) Remove the 4 transfer and transaxle setting stud bolts.

2. RE ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL TRANSFER DRIVEN PINION REAR BEARING

(a) Using SST and a press, press the transfer driven pinion rear bearing

(outer race) to the case.

SST: 09950-6 ...

Other materials about Toyota Venza:

Rear Occupant Classification Sensor LH Collision Detection (B1787)

DESCRIPTION

DTC B1787 is output when the occupant classification ECU receives a collision

detection signal sent by the rear occupant classification sensor LH if an accident

occurs.

DTC B1787 is also output when the front seat assembly RH is subjected to ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL FUEL PRESSURE REGULATOR ASSEMBLY

(a) Apply a light coat of gasoline to 2 new O-rings, and install them

onto the fuel pressure regulator.

Text in Illustration

*1

New O-r ...

USB Audio System Recognition/Play Error

DESCRIPTION

When a USB device or "iPod" is connected to the USB jack of the No. 1 stereo

jack adapter assembly, it must have playable files. The device must also communicate

with and be recognized by the navigation receiver assembly. This diagno ...

0.1156