Toyota Venza: Tachometer Malfunction

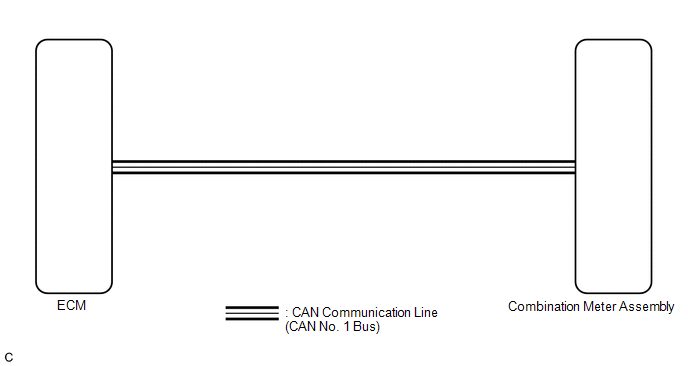

DESCRIPTION

In this circuit, the meter CPU receives engine speed signals from the ECM using the CAN communication system (CAN No. 1 Bus). The meter CPU displays the engine speed calculated based on the data received from the ECM.

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK CAN COMMUNICATION SYSTEM |

(a) Check if a CAN communication DTC is output (See page

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

CAN communication DTC is not output. |

A |

|

CAN communication DTC is output. |

B |

| B | .gif) |

GO TO CAN COMMUNICATION SYSTEM |

|

|

2. |

PERFORM ACTIVE TEST USING TECHSTREAM (TACHO METER OPERATION) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Combination Meter / Active Test.

(e) Check the operation by referring to the table below.

Combination Meter|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Tacho Meter Operation |

Tachometer |

0, 1000, 2000, 3000, 4000, 5000, 6000, 7000 (rpm) |

Confirm that the vehicle is stopped with the engine idling |

OK:

Tachometer indication is normal.

| NG | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

|

|

3. |

READ VALUE USING TECHSTREAM (ENGINE RPM) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Combination Meter / Data List.

(e) Check the values by referring to the table below.

Combination Meter|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Engine Rpm |

Engine speed/Min.: 0 rpm, Max.: 12750 rpm |

650 to 750 rpm (When idling) |

If data received from the ECM exceeds the range that can be displayed on the meter, the meter continues to display the maximum value of the range. |

OK:

Engine speed displayed on the Techstream is almost the same as the tachometer indication.

| NG | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

|

|

4. |

READ VALUE USING TECHSTREAM (ENGINE SPEED) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Data List.

(e) Check the values by referring to the table below.

Engine and ECT|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Engine Speed |

Engine speed/Min.: 0 rpm, Max.: 16383.75 rpm |

650 to 750 rpm (When idling) |

- |

OK:

Engine speed displayed on the Techstream is almost the same as the Techstream indication (Body Electrical / Combination Meter / Data List).

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (for 2GR-FE) |

B |

|

NG (for 1AR-FE) |

C |

| B | .gif) |

GO TO SFI SYSTEM (for 2GR-FE) |

| C | .gif) |

GO TO SFI SYSTEM (for 1AR-FE) |

|

|

5. |

REPLACE ECM |

(a) Replace the ECM with a new or a known good one (See page

.gif) for 2GR-FE,

for 2GR-FE,

.gif) for 1AR-FE).

for 1AR-FE).

OK:

The operation of the tachometer returns to normal.

| OK | .gif) |

END |

| NG | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

Speedometer Malfunction

Speedometer Malfunction

DESCRIPTION

The meter CPU receives vehicle speed signals from the skid control ECU via the

CAN communication system (CAN No. 1 Bus). The speed sensor detects the wheel speed

and sends the appropr ...

Engine Coolant Temperature Receiver Gauge Malfunction

Engine Coolant Temperature Receiver Gauge Malfunction

DESCRIPTION

In this circuit, the meter CPU receives engine coolant temperature signals from

the ECM using the CAN communication system (CAN No. 1 Bus). The meter CPU displays

engine coolant tempe ...

Other materials about Toyota Venza:

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

When troubleshooting OBD II (On-Board Diagnostics) vehicles, an OBD

II scan tool (complying with SAE J1987) must be connected to the DLC3 (Data

Link Connector 3) of the vehicle. Various data in the vehicle ECM ( ...

Checking Monitor Status

CHECKING MONITOR STATUS

The purpose of the monitor result (mode 06) is to allow access to the results

of on-board diagnostic monitoring tests of specific components/systems that are

not continuously monitored. Examples are catalysts and evaporative emissi ...

Stereo Component Amplifier Disconnected (B15D3)

DESCRIPTION

The navigation receiver assembly and stereo component amplifier assembly are

connected via AVC-LAN communication.

This DTC is stored when an AVC-LAN communication error occurs between the navigation

receiver assembly and stereo component ampl ...

0.1582

.gif)