Toyota Venza: Window Defogger Wire

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK REAR WINDOW DEFOGGER SYSTEM OPERATION

(a) When the ignition switch is turned to ON and the rear window defogger switch is pressed, check that the rear window defogger system operates.

2. INSPECT BACK DOOR GLASS (REAR WINDOW DEFOGGER WIRE)

NOTICE:

- When cleaning the glass, wipe the glass along the wire using a soft and dry cloth. Take care not to damage the wires.

- Do not use detergents or glass cleaners that have abrasive ingredients.

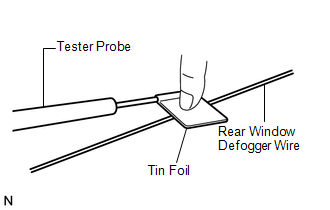

- When measuring voltage, wrap a piece of tin foil around the tip of the

negative tester probe and press the foil against the wire with your finger,

as shown in the illustration.

(a) Turn the ignition switch to ON.

(b) Turn the rear window defogger switch on.

|

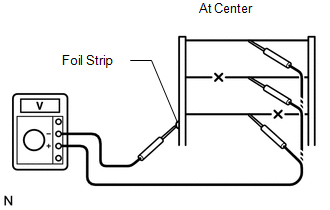

(c) Measure the voltage at the center of each rear window defogger wire to check the wire, as shown in the illustration. Result:

HINT: If the voltage is 11 to 14 V, the wire may be faulty between the center of the wire and the wire end on the battery side. If the voltage is below 1 V, the wire may be faulty between the center of the wire and the wire end on the ground side. |

|

|

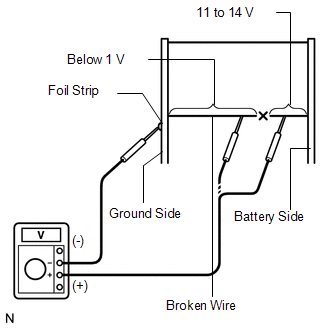

(d) Place a positive (+) lead of the voltmeter against the rear window defogger wire on the battery side. |

|

(e) Place a negative (-) lead of the voltmeter with the foil strip against the wire on the ground side.

(f) Slide the positive (+) lead from the battery side to the ground side. The point where the voltage drops to below 1 V from 11 to 14 V is the place where the rear window defogger wire is broken.

HINT:

If the rear window defogger wire is not broken, the voltmeter should indicate 11 to 14 V at the battery side. When the positive (+) lead slides to the ground side, the voltage gradually decreases to below 1 V.

Repair

REPAIR

PROCEDURE

1. REPAIR REAR WINDOW DEFOGGER WIRE

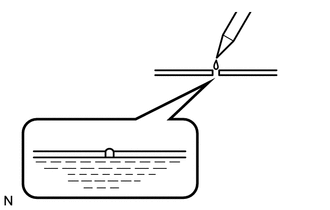

(a) Clean the broken wire tips with a grease, wax and silicone remover.

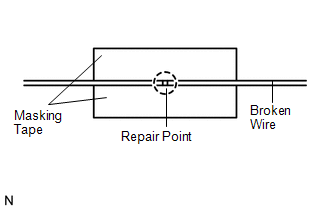

(b) Place masking tape along both sides of the wire.

|

(c) Thoroughly mix the repair agent (Dupont paste No. 4817 or equivalent). |

|

(d) Using a fine tip brush, apply a small amount of the agent to the wire.

(e) After a few minutes, remove the masking tape.

NOTICE:

Do not repair the rear window defogger wire again for at least 24 hours.

Rear Window Defogger System does not Operate

Rear Window Defogger System does not Operate

DESCRIPTION

When the rear window defogger switch on the air conditioning control assembly

is pressed, the operation signal is transmitted to the air conditioning amplifier

assembly through the LI ...

Other materials about Toyota Venza:

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Daytime Running Light Relay Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) controls the daytime

running lights.

WIRING DIAGRAM

1. for Halogen Headlight

2. for HID Headlight

PROCEDURE

1.

PERFORM ACTIVE TEST USING TECHSTREAM

...

Lost Communication with Front Satellite Sensor Bus (B161A/8A)

DESCRIPTION

The front collision sensor circuit (front airbag sensor RH circuit and front

airbag sensor LH circuit) is composed of the center airbag sensor assembly, front

airbag sensor RH and front airbag sensor LH.

The front airbag sensor RH or front ai ...

0.1505