Toyota Venza: Voice Recognition Microphone Disconnected (B1579)

DESCRIPTION

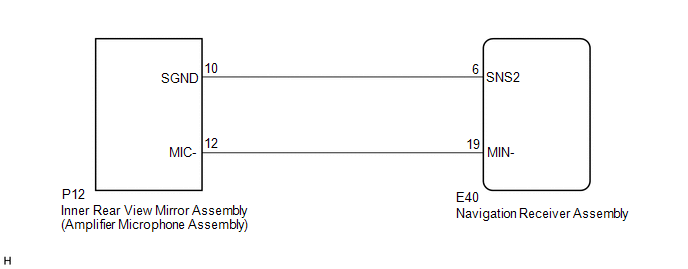

The navigation receiver assembly and inner rear view mirror assembly (amplifier microphone assembly) are connected to each other using the microphone connection detection signal lines.

This DTC is stored when a microphone connection detection signal line is disconnected.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B1579 |

Telephone microphone signal is lost. |

|

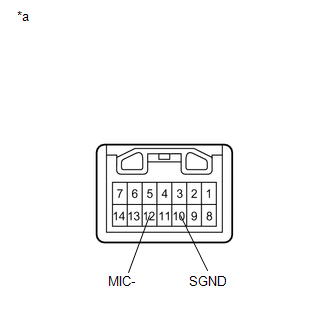

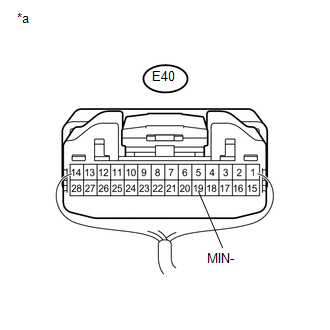

WIRING DIAGRAM

PROCEDURE

|

1. |

INSPECT NAVIGATION RECEIVER ASSEMBLY |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG | .gif) |

REPLACE NAVIGATION RECEIVER ASSEMBLY |

|

|

2. |

CHECK HARNESS AND CONNECTOR (NAVIGATION RECEIVER ASSEMBLY - INNER REAR VIEW MIRROR ASSEMBLY (AMPLIFIER MICROPHONE ASSEMBLY)) |

(a) Disconnect the E40 navigation receiver assembly connector.

(b) Disconnect the P12 inner rear view mirror assembly (amplifier microphone assembly) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E40-6 (SNS2) - P12-10 (SGND) |

Always |

Below 1 Ω |

|

E40-19 (MIN-) - P12-12 (MIC-) |

Always |

Below 1 Ω |

|

E40-6 (SNS2) - Body ground |

Always |

10 kΩ or higher |

|

E40-19 (MIN-) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

INSPECT INNER REAR VIEW MIRROR ASSEMBLY (AMPLIFIER MICROPHONE ASSEMBLY) |

(a) Remove the inner rear view mirror assembly (amplifier microphone assembly)

(See page .gif) ).

).

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK | .gif) |

REPLACE NAVIGATION RECEIVER ASSEMBLY |

| NG | .gif) |

REPLACE INNER REAR VIEW MIRROR ASSEMBLY (AMPLIFIER MICROPHONE ASSEMBLY) |

LVDS Signal Malfunction (from Extension Module) (B1532)

LVDS Signal Malfunction (from Extension Module) (B1532)

DESCRIPTION

The stereo component tuner assembly and the navigation receiver assembly are

connected by the LVDS communication line.

This DTC is stored when an LVDS communication error occurs betwee ...

Sending Malfunction (Navigation to APGS) (U0073,U0100,U0140,U0155)

Sending Malfunction (Navigation to APGS) (U0073,U0100,U0140,U0155)

DESCRIPTION

These DTCs are stored when a malfunction occurs in the CAN communication circuit.

DTC No.

DTC Detection Condition

Trouble Area

U0073

...

Other materials about Toyota Venza:

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT SEAT HEADREST ASSEMBLY

2. REMOVE FRONT SEAT REAR OUTER TRACK COVER

3. REMOVE FRONT SEAT REAR INNER TRACK COVER

4. REMOVE FRONT SEAT ASSEMBLY

5. REMOVE RECLINING POWER SEAT SWITCH KNOB

6. REMOVE SLIDE AND VER ...

LIN Communication Bus Malfunction (B2325)

DESCRIPTION

The main body ECU (driver side junction block assembly) monitors communication

between all the ECUs connected to the door bus lines. When the main body ECU (driver

side junction block assembly) detects errors in communication with all the ECUs ...

Differential Oil Seal

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Remove the No. 2 engine under cover and front fender apron LH.

(b) Using a 6 mm socket hexagon wrench, remove the overflow plug ...

0.1198

.gif)