Toyota Venza: Transmission Fluid Pressure Sensor / Switch "E" Circuit Low (P0989,P0990)

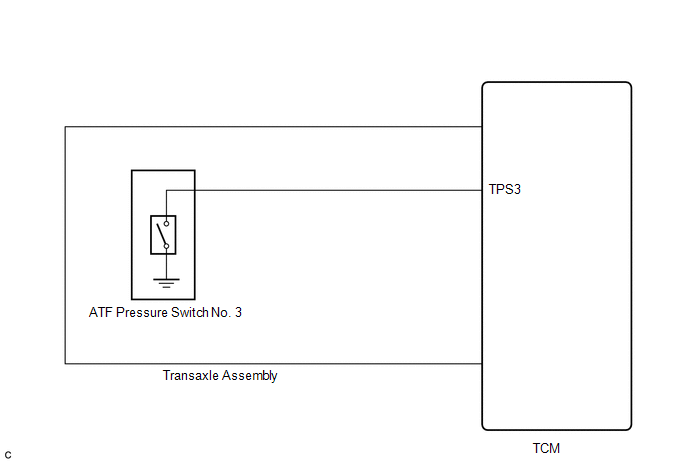

DESCRIPTION

ATF pressure switch No. 3 is installed in the lock-up solenoid ATF output passage and is used to detect a malfunction in the lock-up solenoid.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

P0989 |

Transmission fluid pressure switch No. 3 is OFF when lock-up occurs in response to a lock-up request (2 trip detection logic). |

|

|

P0990 |

When both of the following are detected (2 trip detection logic):

|

MONITOR DESCRIPTION

The TCM illuminates the MIL and stores the DTC when the TCM detects that the ATF pressure switch is OFF with the lock-up solenoid ON or when the TCM detects that the ATF pressure switch is ON with the lock-up solenoid OFF.

MONITOR STRATEGY

|

Related DTCs |

P0989: Transmission fluid pressure switch No. 3 OFF malfunction P0990: Transmission fluid pressure switch No. 3 ON malfunction |

|

Required sensors/Components |

Transmission fluid pressure switch No. 3 |

|

Frequency of operation |

Continuous |

|

Duration |

P0989: 1.8 sec. P0990 (a): 1.2 sec. P0990 (b): 0.6 sec. |

|

MIL operation |

2 driving cycles |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

ALL:|

The monitor will run whenever this DTC is not present. (Not circuit malfunction) |

P0712, P0713 (ATF temperature sensor circuit (TFT sensor)) P0115, P0117, P0118 (ECT sensor circuit) P0715, P0717 (Turbine speed sensor circuit) P0791, P0793 (Intermediate shaft speed sensor circuit) P0748 (Shift solenoid valve SL1 circuit) P0778 (Shift solenoid valve SL2 circuit) P0798 (Shift solenoid valve SL3 circuit) P2810 (Shift solenoid valve SL4 circuit) P2759 (Shift solenoid valve SLU circuit) P2769, P2770 (Shift solenoid valve SL circuit) P0327, P0328, P0332, P0333 (KCS sensor circuit) P0120, P0121, P0122, P0123, P0220, P0222, P0223, P0604, P0606, P060A, P060B, P060D, P060E, P0657, P1607, P2102, P2103, P2111, P2112, P2118, P2119, P2135 ((ETCS) Electronic throttle control system) U0100 (CAN communication system) |

|

ECT (Engine coolant temperature) |

40°C (104°F) or more |

|

Spark advance from Max. retard timing by KCS control |

0°CA or more |

|

Transmission range |

"D" |

|

TFT (Transmission fluid temperature) |

-10°C (14°F) or more |

|

TFT (Transmission fluid temperature) sensor circuit |

No circuit malfunction |

|

ECT (Engine coolant temperature) sensor circuit |

No circuit malfunction |

|

Turbine speed sensor circuit |

No circuit malfunction |

|

Intermediate shaft speed sensor circuit |

No circuit malfunction |

|

Shift solenoid valve SL1 circuit |

No circuit malfunction |

|

Shift solenoid valve SL2 circuit |

No circuit malfunction |

|

Shift solenoid valve SL3 circuit |

No circuit malfunction |

|

Shift solenoid valve SL4 circuit |

No circuit malfunction |

|

Shift solenoid valve SLU circuit |

No circuit malfunction |

|

Shift solenoid valve SL circuit |

No circuit malfunction |

|

(KCS) Knock control sensor circuit |

No circuit malfunction |

|

(ETCS) Electronic throttle control system |

Not system down |

|

CAN communication system |

Not system down |

|

Engine |

Starting |

|

TCM selected gear |

Not 1st |

|

Vehicle speed |

15.5 mph (25 km/h) or more |

|

Turbine speed/Output speed (NT/NO) with 1st |

3.304 to 7.724 |

|

Turbine speed/Output speed (NT/NO) with 2nd |

1.901 to 2.340 |

|

Turbine speed/Output speed (NT/NO) with 3rd |

1.399 to 1.649 |

|

Turbine speed/Output speed (NT/NO) with 4th |

0.998 to 1.138 |

|

Turbine speed/Output speed (NT/NO) with 5th |

0.705 to 0.836 |

|

Turbine speed/Output speed (NT/NO) with 6th |

0.568 to 0.695 |

|

TCM lock-up command |

ON |

|

Engine speed - Turbine speed |

Less than 35 rpm |

|

Throttle valve opening angle |

7% or more |

|

Vehicle speed |

Less than 62.1 mph (100 km/h) |

|

Shift solenoid valve SLU |

Not ON malfunction |

|

TCM indicated pressure valve of SLU |

Less than 4 kPa |

|

TCM lock-up command |

OFF |

|

Shift solenoid valve SLU |

Not malfunction |

|

Shift solenoid valve SL |

Not OFF malfunction |

TYPICAL MALFUNCTION THRESHOLDS

P0989:|

Transmission fluid pressure switch No. 3 |

OFF |

|

Following conditions are met |

(a) and (b) |

|

(a) Engine speed - Turbine speed |

35 rpm or more |

|

(b) Transmission fluid pressure switch No. 3 |

ON |

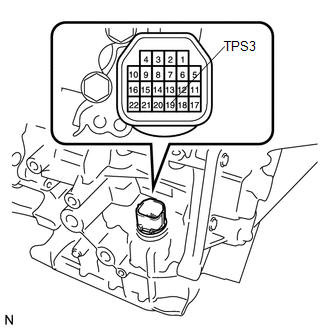

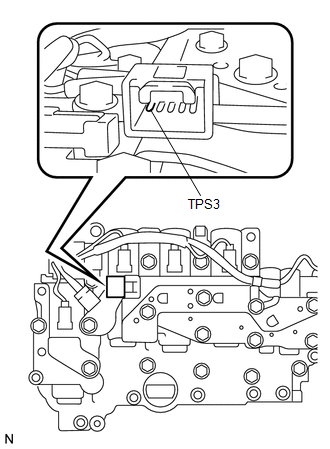

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Perform the universal trip to clear permanent DTCs (See page

.gif) ).

).

PROCEDURE

|

1. |

CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P0989 OR P0990) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / ECT / Trouble Codes.

(e) Read the DTCs using the Techstream.

|

Display (DTC Output) |

Proceed to |

|---|---|

|

Only "P0990" is output |

A |

|

Only "P0989" is output |

B |

|

"P0989 or P0990" and other DTCs are output |

C |

HINT:

If a solenoid is stuck OFF, DTCs for several solenoids including the malfunctioning solenoid will be detected.

| B | .gif) |

GO TO STEP 4 |

| C | .gif) |

GO TO DTC CHART |

|

|

2. |

CHECK TRANSMISSION WIRE (SHORT TO GROUND) |

|

(a) Remove the TCM. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

19 (TPS3) - Body ground (Valve body assembly) or other terminals |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE TCM |

|

|

3. |

CHECK ATF TEMPERATURE SENSOR ASSEMBLY (ATF PRESSURE SWITCH NO. 3) |

(a) Remove the oil strainer assembly.

|

(b) Disconnect the connector from the ATF temperature sensor assembly. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (TPS3) - Body ground (Valve body assembly) or other terminals |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE TRANSMISSION WIRE |

| NG | .gif) |

REPLACE ATF TEMPERATURE SENSOR ASSEMBLY |

|

4. |

CHECK TRANSMISSION WIRE |

(a) Remove the oil strainer assembly.

|

(b) Remove the TCM. |

|

(c) Disconnect the connector from the ATF temperature sensor assembly.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

19 (TPS3) TCM side - 1 (TPS3) sensor side |

Always |

Below 1 Ω |

|

1 (TPS3) sensor side - Body ground (Valve body assembly) or other terminals |

Always |

10 kΩ or higher |

|

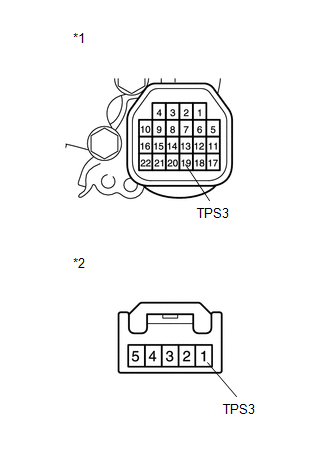

*1 |

Front view of wire harness connector (to TCM) |

|

*2 |

Front view of wire harness connector (to ATF Temperature Sensor Assembly) |

| NG | .gif) |

REPLACE TRANSMISSION WIRE |

|

|

5. |

REPLACE ATF TEMPERATURE SENSOR ASSEMBLY |

(a) (See page .gif) ).

).

|

|

6. |

CHECK IF DTC OUTPUT RECURS |

(a) Connect the Techstream to the DLC3.

(b) Start the engine and turn the Techstream on.

(c) Enter the following menus: / ECT / DTC / Clear.

HINT:

Write down the currently output DTCs before clearing them.

(d) Perform the monitor drive pattern (See page

.gif) ).

).

(e) Enter the following menus: / ECT / DTC.

(f) Read the DTCs using the Techstream.

|

Display (DTC Output) |

Proceed to |

|---|---|

|

Only "P0989" is output |

A |

|

No output |

B |

| A | .gif) |

REPLACE TCM |

| B | .gif) |

END |

Pressure Control Solenoid "C" Electrical (Shift Solenoid Valve SL3) (P0798)

Pressure Control Solenoid "C" Electrical (Shift Solenoid Valve SL3) (P0798)

DESCRIPTION

Changing from 1st to 6th is performed by the TCM turning shift solenoid valves

SL1, SL2, SL3, SL4 and SL on and off. If an open or short circuit occurs in any

of the shift solenoid va ...

Pressure Control Solenoid "C" Performance (Shift Solenoid Valve SL3) (P0796)

Pressure Control Solenoid "C" Performance (Shift Solenoid Valve SL3) (P0796)

SYSTEM DESCRIPTION

The TCM uses the vehicle speed signal and signals from the transmission speed

sensors (NC, NT) to detect the actual gear (1st, 2nd, 3rd, 4th, 5th or 6th gear).

Then the TCM comp ...

Other materials about Toyota Venza:

Fail-safe Chart

FAIL-SAFE CHART

1. Fail-safe

This function minimizes the loss of operation when any abnormality occurs in

a sensor or solenoid.

Fail-safe Control List

Malfunction Part

Function

Input Turbine Speed Sensor

...

Check Mode Procedure

CHECK MODE PROCEDURE

1. CHECK MODE (SIGNAL CHECK): DTC CHECK

(a) Turn the ignition switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the Techstream on.

(e) Enter the following menus: Body Electrical / SRS Ai ...

Tongue Plate Stopper

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. REMOVE TONGUE PLATE STOPPER

(a) Slide the tongue plate above the installation position of the tongue

plate stopper, and temporarily hold it with adhesive tape.

...

0.1198

.gif)