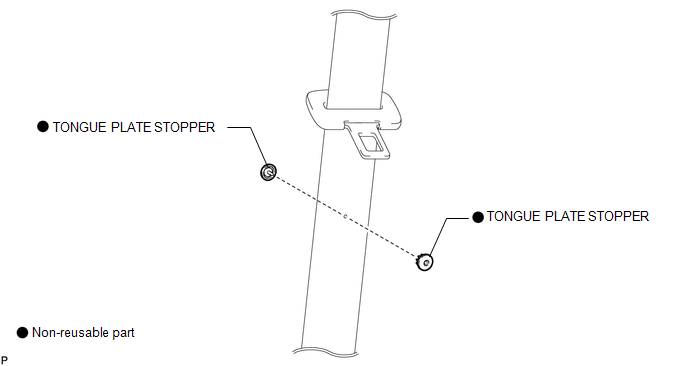

Toyota Venza: Tongue Plate Stopper

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. REMOVE TONGUE PLATE STOPPER

|

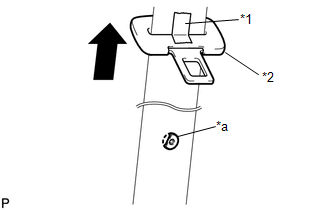

(a) Slide the tongue plate above the installation position of the tongue plate stopper, and temporarily hold it with adhesive tape. |

|

(b) Remove any pieces of the original tongue plate stopper in the belt webbing with a pair of pliers.

NOTICE:

Be careful not to damage the belt webbing during repair.

Text in Illustration|

*1 |

Adhesive Tape |

|

*2 |

Tongue Plate |

|

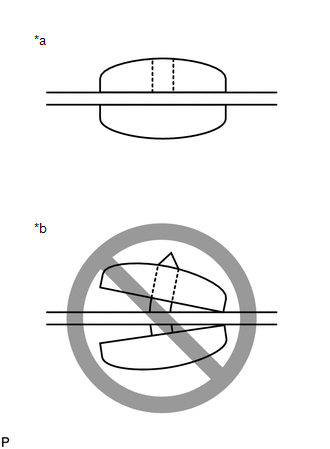

*a |

Broken Tongue Plate Stopper |

2. INSTALL TONGUE PLATE STOPPER

|

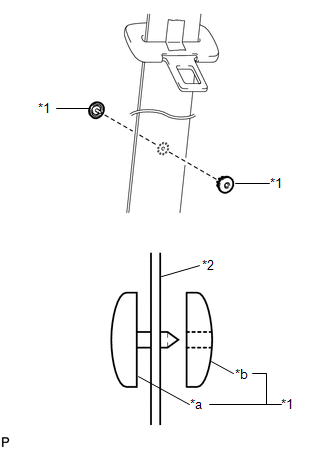

(a) Position a new tongue plate stopper in the hole of the belt webbing. Text in Illustration

HINT: Make sure that the installation direction of the tongue plate stopper is as shown in the illustration. |

|

|

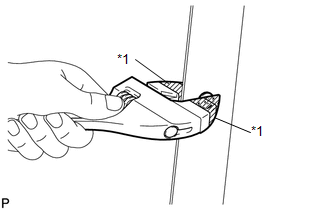

(b) Hold the tongue plate stopper in the hole of the belt webbing using an adjustable wrench, and turn the adjustment screw of the adjustable wrench by hand to compress the tongue plate stopper. Text in Illustration

NOTICE:

HINT: Tape the jaws of the adjustable wrench before use. |

|

|

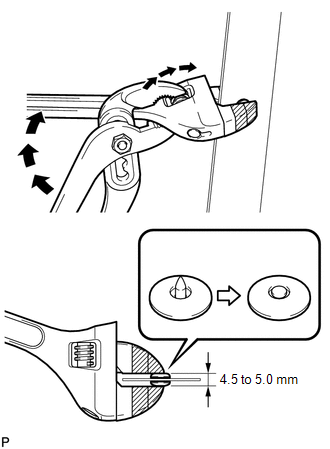

(c) When the adjustment screw of the adjustable wrench cannot be turned by hand, tighten the adjustment screw using a pair of adjustable joint pliers until the tongue plate stopper thickness is 4.5 to 5.0 mm (0.177 to 0.197 in.). (Refer to the illustrations.) |

|

|

(d) Make sure that the male pin of the tongue plate stopper has expanded evenly in the hole of the female part and is firmly held to the belt webbing. (Refer to the illustrations.) Text in Illustration

|

|

Front Passenger Side Seat Belt Warning Light Malfunction

Front Passenger Side Seat Belt Warning Light Malfunction

DESCRIPTION

The occupant classification ECU detects the state of the front seat inner belt

assembly RH and load sensor when the front passenger side seat is occupied with

the ignition switch ON. ...

Other materials about Toyota Venza:

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure to troubleshoot the smart key system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

...

How To Proceed With Troubleshooting

PROCEDURE

1.

CHECK TIRE AND WHEEL SYSTEM

DIAGNOSIS OF IRREGULAR TIRE WEAR

GO TO STEP 11

DIAGNOSIS OF TIRE VIBRATION

2.

...

Dtc Check / Clear

DTC CHECK / CLEAR

1. CHECK DTC

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Driver Seat / Trouble Codes.

(e) Check for DTCs (See page ).

2. CLEA ...

0.1194