Toyota Venza: Transfer Case Rear Oil Seal

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

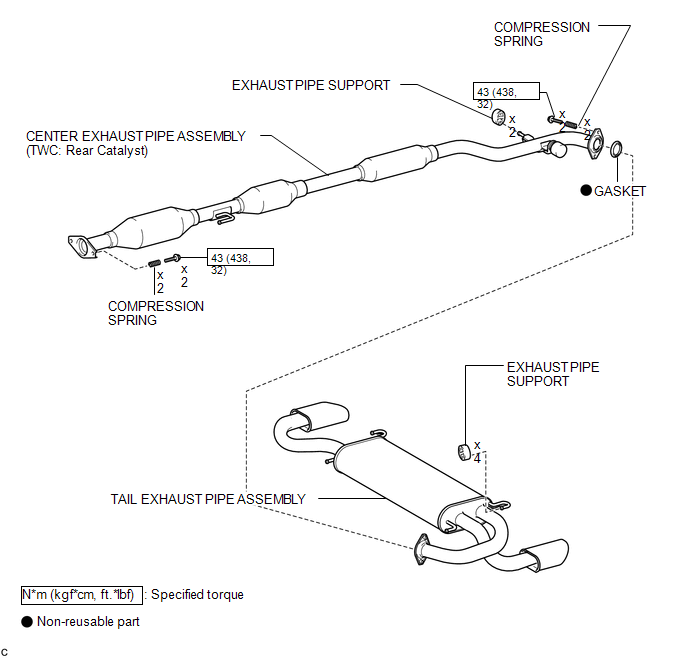

1. REMOVE TAIL EXHAUST PIPE ASSEMBLY

.gif)

2. REMOVE CENTER EXHAUST PIPE ASSEMBLY

.gif)

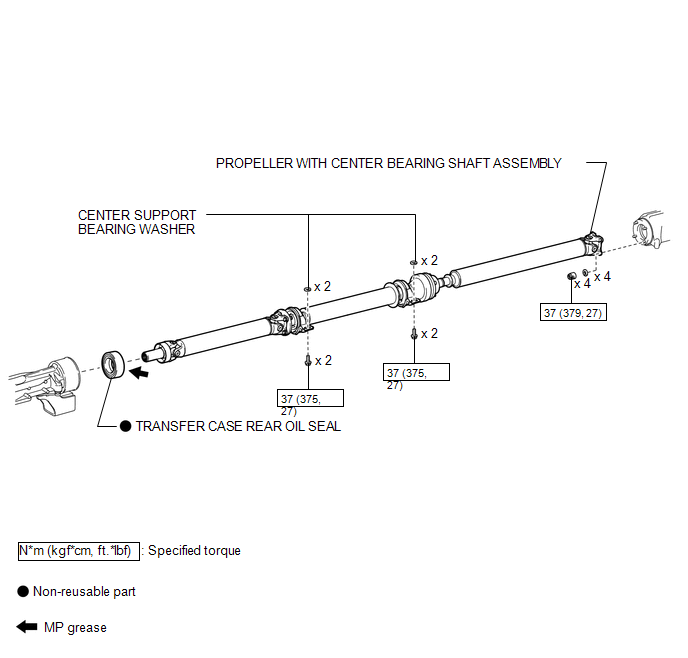

3. REMOVE PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

.gif)

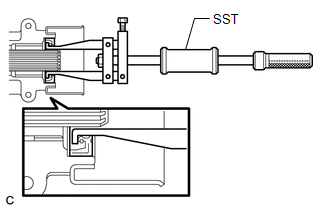

4. REMOVE TRANSFER CASE REAR OIL SEAL

|

(a) Using SST, remove the transfer case rear oil seal from the transfer extension housing sub-assembly. SST: 09308-00010 NOTICE: Be careful not to damage the oil seal contact surface or the inside surface of the oil seal. |

|

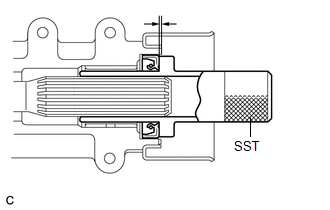

5. INSTALL TRANSFER CASE REAR OIL SEAL

|

(a) Using SST and a hammer, drive in a new transfer case rear oil seal into the transfer extension housing sub-assembly until it reaches the position shown in the illustration. SST: 09325-20010 Drive in depth: 1.1 to 1.9 mm (0.0433 to 0.0748 in.) NOTICE: Do not tilt the oil seal during installation. |

|

(b) Apply a small amount of MP grease to the lip of the oil seal.

6. TEMPORARILY TIGHTEN PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

.gif)

7. FULLY TIGHTEN PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

.gif)

8. INSTALL CENTER EXHAUST PIPE ASSEMBLY

.gif)

9. INSTALL TAIL EXHAUST PIPE ASSEMBLY

.gif)

10. INSPECT TRANSFER OIL

.gif)

11. INSPECT EXHAUST GAS LEAK

Transfer Case Front Oil Seal(for Rh Side)

Transfer Case Front Oil Seal(for Rh Side)

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. DRAIN TRANSFER OIL

(a) Remove the transfer drain plug and gasket to drain the transfer oil.

(b) Install a new gask ...

Transfer Oil

Transfer Oil

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT TRANSFER OIL

(a) Remove the No. 1 transfer case plug and gasket.

...

Other materials about Toyota Venza:

Oxygen (A/F) Sensor Signal Stuck Lean (Bank 1 Sensor 1) (P2195,P2196)

DESCRIPTION

HINT:

Although the DTC titles say oxygen sensor, these DTCs relate to the

air fuel ratio sensor.

Sensor 1 refers to the sensor mounted in front of the three-way catalytic

converter and located near the engine assembly.

...

Check For Intermittent Problems

CHECK FOR INTERMITTENT PROBLEMS

1. CHECK FOR INTERMITTENT PROBLEMS

HINT:

A momentary interruption (open circuit) in the connectors and/or wire harness

between the sensors and ECUs can be detected using the ECU Data List function of

the Techstream.

(a) ...

Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the piston or piston ring (See

page ).

PROCEDURE

1. INSTALL STUD BOLT

NOTICE:

If a stud bolt is deformed or the threads are damaged, replace it.

(a) ...

0.1197