Toyota Venza: Torque Converter And Drive Plate

Inspection

INSPECTION

PROCEDURE

1. INSPECT TORQUE CONVERTER ASSEMBLY

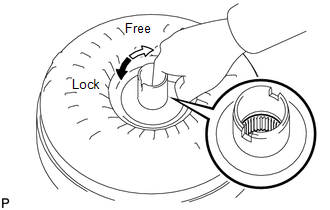

(a) Inspect the one-way clutch.

|

(1) Press on the serrations of the stator with a finger and rotate it. Check that it rotates smoothly when turned clockwise and locks when turned counterclockwise. If necessary, clean the converter and recheck the one-way clutch. Replace the converter if the one-way clutch still fails the check. |

|

|

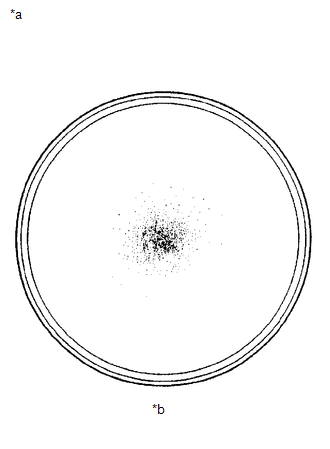

(b) Determine the condition of the torque converter assembly. Text in Illustration

(1) Check that the following conditions are met:

If the results are not as specified, replace the torque converter assembly. HINT: The sample illustration shows approximately 0.25 liters (0.26 US qts, 0.22 Imp. qts) of ATF taken from a removed torque converter. |

|

(c) Replace the ATF in the torque converter.

(1) If the ATF is discolored and/or has foul odor, stir the ATF in the torque converter thoroughly and drain it.

|

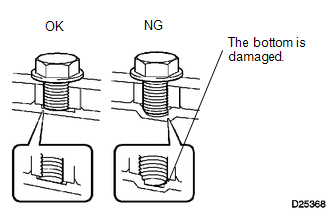

(d) Avoid damaging the torque converter and the oil pump gear. (1) When any marks due to interference are found on the end of a bolt for the torque converter or on the bottom of a bolt hole, replace the bolt and torque converter. (2) All of the bolts should be the same length. (3) Make sure that no spring washers are missing. |

|

2. INSPECT DRIVE PLATE

|

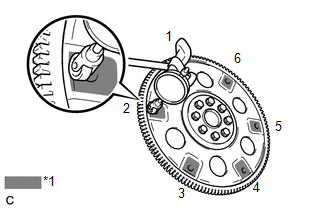

(a) Set up a dial indicator and measure the runout of the 6 portions around the torque converter contact surfaces. Text in Illustration

Maximum runout: 0.30 mm (0.0118 in.) |

|

(b) Check the drive plate damage.

If the runout is not within the specification or the drive plate is damaged, replace the drive plate.

Tcm

Tcm

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

If automatic transmission parts are replaced, refer to Parts Replacement Compensation

Table to determi ...

Other materials about Toyota Venza:

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure to troubleshoot.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

2.

CUSTOMER PR ...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use these procedure to troubleshoot the sliding roof system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

...

Precaution

PRECAUTION

1. PRECAUTION FOR DISCONNECTING THE BATTERY CABLE

NOTICE:

When disconnecting the cable from the negative (-) battery terminal, initialize

the following systems after the cable is reconnected:

System

See Procedure

...

0.128