Toyota Venza: Tire Pressure Warning Light Circuit

DESCRIPTION

If the tire pressure warning ECU detects a malfunction, the tire pressure warning light blinks for 1 minute then stays on and tire pressure monitor is canceled at the same time. At this time, the ECU records a DTC in the memory.

Connecting terminals TC and CG of the DLC3 allows the tire pressure warning light to blink output DTCs.

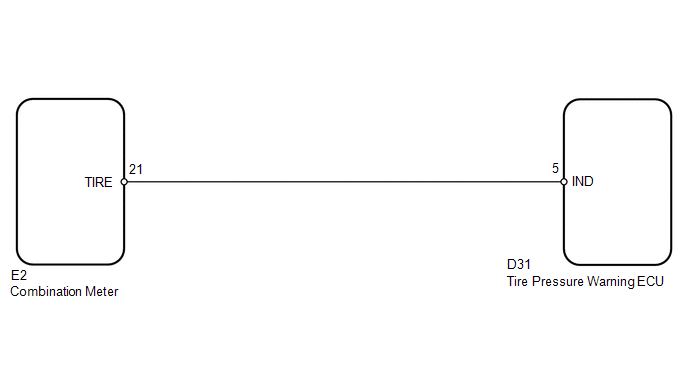

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When replacing the tire pressure warning ECU, read the transmitter IDs stored in the old ECU using the Techstream and write them down before removal.

- It is necessary to perform registration (See page

.gif) ) of the transmitter IDs into the tire

) of the transmitter IDs into the tire

pressure warning ECU if the ECU has been replaced.

PROCEDURE

|

1. |

CHECK OPERATION OF TIRE PRESSURE WARNING LIGHT (ACTIVE TEST) |

(a) Turn the ignition switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the Techstream on.

(e) Enter the following menus: Body Electrical / Combination Meter / Active Test.

(f) Check the condition of the tire pressure warning light by operating the Techstream.

Combination Meter|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Indicat. Tire Pressure Warning System |

Tire pressure warning light |

Tire pressure warning light is off or on |

Confirm that the vehicle is stopped with the engine idling |

OK:

The warning light turns on when operating the Techstream.

| NG | .gif) |

GO TO METER / GAUGE SYSTEM |

|

|

2. |

CHECK HARNESS AND CONNECTOR (COMBINATION METER - TIRE PRESSURE WARNING ECU) |

|

(a) Disconnect the E2 combination meter connector. |

|

(b) Disconnect the D31 tire pressure warning ECU connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E2-21 (TIRE) - D31-5 (IND) |

Always |

Below 1 Ω |

|

E2-21 (TIRE) - Body ground |

10 kΩ or higher |

|

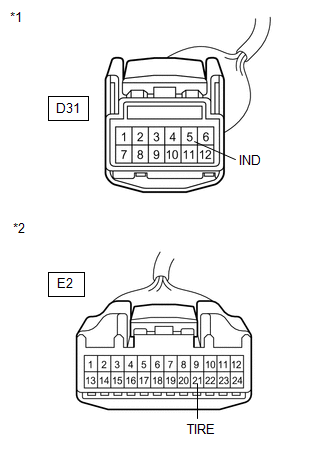

*1 |

Front view of wire harness connector (to Tire Pressure Warning ECU) |

|

*2 |

Front view of wire harness connector (to Combination Meter) |

| OK | .gif) |

REPLACE TIRE PRESSURE WARNING ECU |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

ECU Power Source Circuit

ECU Power Source Circuit

DESCRIPTION

This is the power source for the tire pressure warning ECU.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

When replacing the tire pressure warning ECU, read the transmitter ...

TC and CG Terminal Circuit

TC and CG Terminal Circuit

DESCRIPTION

DTC output mode is set by connecting terminals 13 (TC) and 4 (CG) of the DLC3.

The DTCs are indicated by the blinking pattern of the tire pressure warning light.

WIRING DIAGRAM

HINT ...

Other materials about Toyota Venza:

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE NO. 2 ANTENNA CORD SUB-ASSEMBLY (w/o Sliding Roof)

2. REMOVE NO. 2 ANTENNA CORD SUB-ASSEMBLY (w/ Sliding Roof)

3. REMOVE VANITY LIGHT ASSEMBLY

(a) Remove the vanity light assembly (See page

).

HINT:

Use the same p ...

Engine Coolant Temperature / Intake Air Temperature Correlation (P011B)

DESCRIPTION

The engine has two temperature sensors, an engine coolant temperature sensor

and an intake air temperature sensor, to detect the temperature while the engine

is in operation. A thermistor, whose resistance value varies according to the tempera ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT DRIVER SIDE SEAT BELT WARNING

(a) Turn the ignition switch to ON.

(b) When the driver side seat belt is not fastened, check that the driver side

seat belt warning light on the combination meter assembly blinks.

...

0.1347

.gif)