Toyota Venza: Terminals Of Ecu

TERMINALS OF ECU

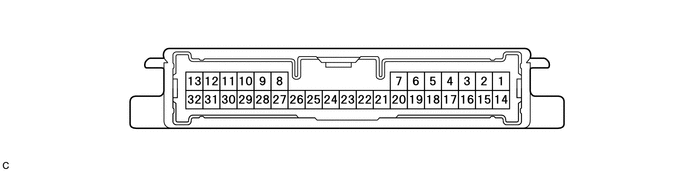

1. CHECK AWD CONTROL ECU

(a) Measure the voltage and resistance of the connector.

|

Terminal No. (Symbol) |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|

|

14 (CANH) - 16 (CANL) |

CAN communication |

Ignition switch off |

54 to 69 Ω |

|

23 (GND) - Body ground |

Ground |

Always |

Below 1 Ω |

|

11 (IG1) - 23 (GND) |

Power source voltage |

Ignition switch ON |

10 to 14 V |

|

13 (SLC+) - 32 (SLC-) |

Electromagnetic solenoid signal |

D position, Idling |

Pulse generation (See waveform 1) |

|

9 (BSLC) - 23 (GND) |

Power source voltage |

Always |

10 to 14 V |

If the result is not as specified, the AWD control ECU may have a malfunction.

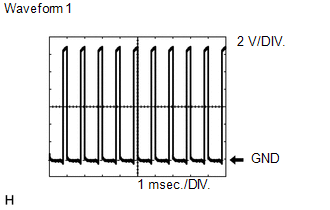

(b) Using an oscilloscope, check the waveform 1.

Waveform 1 (Reference)

Waveform 1 (Reference)

|

Terminal Name |

Content |

|---|---|

|

Tester Range |

2 V/DIV., 1 msec./DIV. |

|

Condition |

D position, Idling |

Test Mode Procedure

Test Mode Procedure

TEST MODE PROCEDURE

1. DESCRIPTION

HINT:

When using a chassis dynamometer, brake tester, etc. to perform a vehicle test,

activate test mode to avoid a "different tire diameter installed" ...

Diagnosis System

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

Active torque control 4WD system data can be read in the Data Link Connector

3 (DLC3) of the vehicle. When the system seems to be malfunctioning, use the Techstream ...

Other materials about Toyota Venza:

Front Wiper Rubber

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. REMOVE FRONT WIPER BLADE

(a) Remove the holder of the front wiper blade.

(b) Remove the front wiper blade from the f ...

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. REMOVE REAR DOOR INSIDE HANDLE BEZEL PLUG

3. REMOVE REAR P ...

Power Source Mode does not Change to ON (IG and ACC)

DESCRIPTION

When the engine switch is pushed with the electrical key in the cabin, the power

management control ECU receives signals to change the power source mode.

HINT:

To allow use of the Techstream to inspect the push-button start function when

the ...

0.1313