Toyota Venza: TC and CG Terminal Circuit

DESCRIPTION

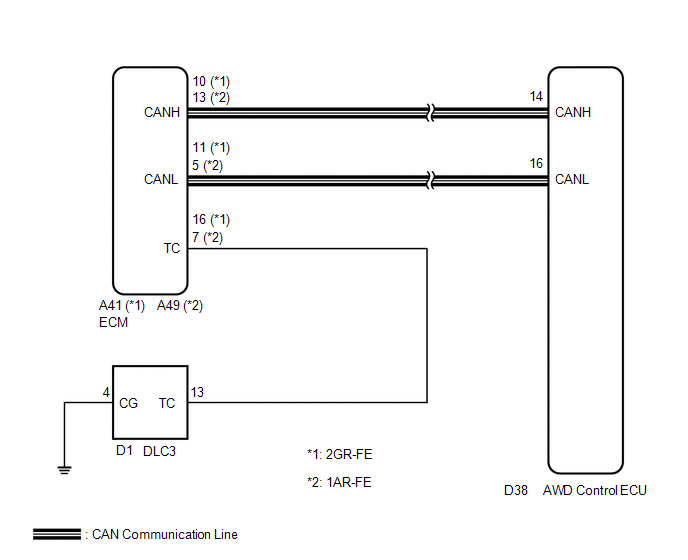

Connecting terminals TC and CG of the DLC3 causes the AWD control ECU to display 2-digit DTCs by flashing the AWD warning light.

HINT:

When each warning light remains blinking, a short to ground in the wiring of terminal TC of the DLC3 or an internal short to ground in each ECU is suspected.

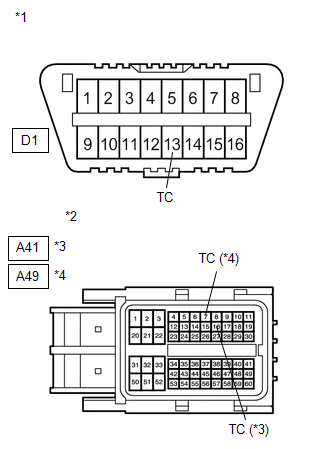

WIRING DIAGRAM

CAUTION / NOTICE / HINT

HINT:

Check the condition of each related circuit connector before troubleshooting

(See page .gif) ).

).

PROCEDURE

|

1. |

CHECK CAN COMMUNICATION SYSTEM |

(a) Check if the CAN communication DTC is output (See page

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTC is not output |

A |

|

DTC is output |

B |

| B | .gif) |

REPAIR CAN COMMUNICATION SYSTEM |

|

|

2. |

CHECK WIRE HARNESS (TC OF DLC3 - TC OF ECM AND BODY GROUND) |

|

(a) Turn the ignition switch off. |

|

(b) Disconnect the ECM connector.

(c) Measure the resistance of the wire harness side connectors.

Standard Resistance:

|

Tester Connection (DLC3 - ECM) |

Condition |

Specified Condition |

|---|---|---|

|

D1-13 (TC) - A41-16 (TC) |

Always |

Below 1 Ω |

|

D1-13 (TC) - A49-7 (TC) |

Always |

Below 1 Ω |

|

D1-13 (TC) - Body Ground |

Always |

10 kΩ or higher |

|

*1 |

DLC3 |

|

*2 |

Front view of wire harness connector (to ECM) |

|

*3 |

2GR-FE |

|

*4 |

1AR-FE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

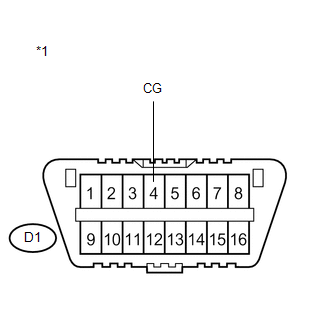

CHECK WIRE HARNESS (CG OF DLC3 - BODY GROUND) |

|

(a) Measure the resistance of the DLC3. Standard Resistance:

|

|

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

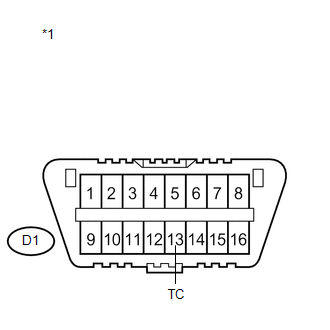

CHECK WIRE HARNESS (TC OF DLC3 - BODY GROUND) |

|

(a) Measure the resistance of the DLC3. Standard Resistance:

|

|

| OK | .gif) |

REPLACE AWD CONTROL ECU |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

AWD Warning Light Remains ON

AWD Warning Light Remains ON

DESCRIPTION

The AWD control ECU is connected to the combination meter via the CAN communication

system.

If the AWD control ECU stores any DTCs which are related to the active torque

control 4WD ...

Other materials about Toyota Venza:

System Diagram

SYSTEM DIAGRAM

Transmitting ECU (Transmitter)

Receiving ECU

Signal

Communication Method

Skid control ECU

Steering angle sensor

Steering angle sensor request signal

...

Camshaft Position Sensor

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL CAMSHAFT POSITION SENSOR (for Exhaust Side)

(a) Apply a light coat of engine oil to the O-ring of the camshaft position sensor.

NOTICE:

If reusing the camshaft pos ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FRONT BUMPER SIDE RETAINER LH

(a) Engage the claw and install the front bumper side retainer LH.

Text in Illustration

*1

Bolt

*2

S ...

0.1175

.gif)