Toyota Venza: TC and CG Terminal Circuit

DESCRIPTION

Connecting terminals TC and CG of the DLC3 causes the system to enter self-diagnostic mode. If a malfunction is present, the MIL will blink.

HINT:

When a particular warning light remains blinking, a ground short in the wiring of terminal TC of the DLC3 or an internal ground short in the relevant ECU is suspected.

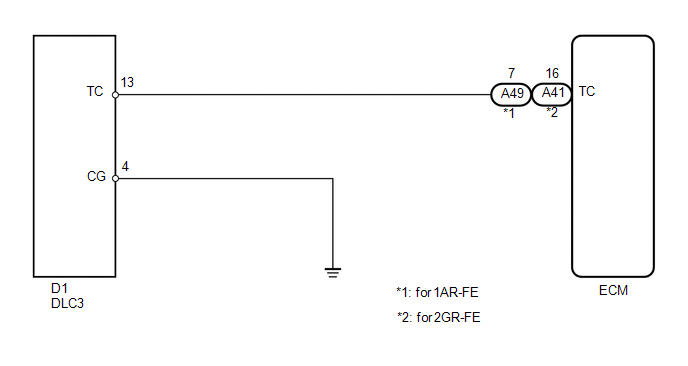

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (DLC3 - ECM) |

(a) Disconnect the ECM connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

For 1AR-FE|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D1-13 (TC) - A49-7 (TC) |

Always |

Below 1 Ω |

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D1-13 (TC) - A41-16 (TC) |

Always |

Below 1 Ω |

|

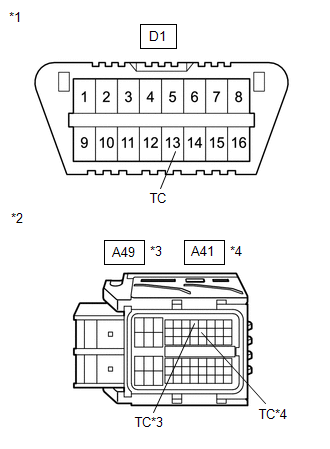

*1 |

DLC3 |

|

*2 |

Front view of wire harness connector (to ECM) |

|

*3 |

for 1AR-FE |

|

*4 |

for 2GR-FE |

(c) Reconnect the ECM connector.

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (DLC3 - ECM) |

|

|

2. |

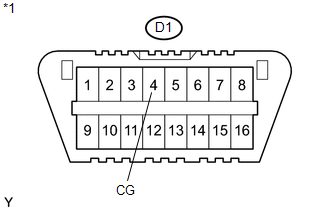

CHECK HARNESS AND CONNECTOR (DLC3 - BODY GROUND) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D1-4 (CG) - Body ground |

Always |

Below 1 Ω |

|

*1 |

DLC3 |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (DLC3 - BODY GROUND) |

|

|

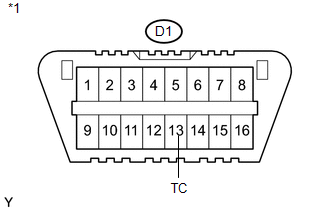

3. |

CHECK HARNESS AND CONNECTOR (DLC3 - BODY GROUND) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D1-13 (TC) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

DLC3 |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR OR EACH ECU |

Cruise SET Indicator Light Circuit

Cruise SET Indicator Light Circuit

DESCRIPTION

The ECM detects a cruise control switch signal and sends it to the combination

meter assembly through CAN. Then the SET indicator light comes on.

The SET indicator light ci ...

Other materials about Toyota Venza:

Mass or Volume Air Flow Circuit Low Input (P0102,P0103)

DESCRIPTION

The mass air flow meter is a sensor that measures the amount of air flowing through

the throttle valve. The ECM uses this information to determine the fuel injection

time and to provide the appropriate air-fuel ratio.

Inside the mass air flow ...

Front Door Courtesy Switch

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT COURTESY LIGHT SWITCH

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Switch C ...

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) Air conditioning system data and the Diagnostic Trouble Codes (DTCs) can

be read through the Data Link Connector 3 (DLC3) of the vehicle. When the system

seems to be malfunctioning, use the Techstream to check for malf ...

0.1289

.gif)