Toyota Venza: Sliding Roof does not Move by Operating Sliding Roof Control Switch

DESCRIPTION

The sliding roof ECU (sliding roof drive gear sub-assembly) receives switch slide and tilt signals and drives its built-in motor.

WIRING DIAGRAM

.png)

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

- When the sliding roof ECU (sliding roof drive gear sub-assembly) is

reinstalled or replaced, the sliding roof drive gear sub-assembly must be

initialized (See page

.gif) ).

). - Since the sliding roof system uses LIN communication, first confirm

that there is no malfunction in the communication system by inspecting the

LIN communication functions in accordance with the How to Proceed with Troubleshooting

procedure (See page

.gif) ). Then, conduct

). Then, conduct

the following inspection procedure.

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM (SLIDING ROOF OPERATION) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Sliding Roof / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Sliding Roof (Sliding Roof ECU (Sliding Roof Drive Gear Sub-assembly))|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Slide Roof |

Operate sliding roof |

CLOS/UP / OFF |

- |

|

Slide Roof |

Operate sliding roof |

OPN/DWN / OFF |

- |

OK:

Sliding roof operates normally.

| NG | .gif) |

GO TO STEP 3 |

|

|

2. |

READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Sliding Roof / Data List.

(e) Read the Data List according to the display on the Techstream.

Sliding Roof (Sliding Roof ECU (Sliding Roof Drive Gear Sub-assembly))|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Open SW |

SLIDE OPEN switch signal/ON or OFF |

ON: SLIDE OPEN switch pressed OFF: SLIDE OPEN switch not pressed |

- |

|

Close SW |

SLIDE CLOSE switch signal/ON or OFF |

ON: SLIDE CLOSE switch pressed OFF: SLIDE CLOSE switch not pressed |

- |

|

Up SW |

TILT UP switch signal/ON or OFF |

ON: TILT UP switch pressed OFF: TILT UP switch not pressed |

- |

|

Down SW |

TILT DOWN switch signal/ON or OFF |

ON: TILT DOWN switch pressed OFF: TILT DOWN switch not pressed |

- |

OK:

The Techstream display changes according to switch operation as shown in the table.

| OK | .gif) |

REPLACE SLIDING ROOF ECU (SLIDING ROOF DRIVE GEAR SUB-ASSEMBLY) |

| NG | .gif) |

GO TO STEP 4 |

|

3. |

CHECK HARNESS AND CONNECTOR (SLIDING ROOF ECU - BATTERY, BODY GROUND) |

|

(a) Disconnect the P4 ECU connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

P4-1 (B) - Body ground |

Always |

11 to 14 V |

|

P4-5 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

|

P4-5 (IG) - Body ground |

Ignition switch off |

Below 1 V |

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

P4-2 (E) - Body ground |

Always |

Below 1 Ω |

|

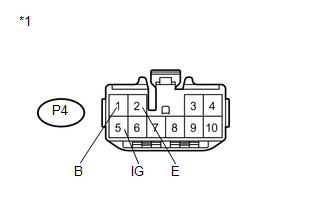

*1 |

Front view of wire harness connector (to Sliding Roof ECU (Sliding Roof Drive Gear Sub-assembly)) |

| OK | .gif) |

REPLACE SLIDING ROOF ECU (SLIDING ROOF DRIVE GEAR SUB-ASSEMBLY) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

4. |

CHECK HARNESS AND CONNECTOR (SLIDING ROOF ECU - SLIDING ROOF SWITCH ASSEMBLY) |

|

(a) Disconnect the P6 switch connector. |

|

(b) Disconnect the P4 ECU connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

P4-9 (CLS) - P6-2 (CLS) |

Always |

Below 1 Ω |

|

P4-9 (CLS) - Body ground |

Always |

10 kΩ or higher |

|

P4-7 (OPN) - P6-3 (OPN) |

Always |

Below 1 Ω |

|

P4-7 (OPN) - Body ground |

Always |

10 kΩ or higher |

|

P4-8 (DWN) - P6-4 (DOWN) |

Always |

Below 1 Ω |

|

P4-8 (DWN) - Body ground |

Always |

10 kΩ or higher |

|

P4-10 (UP) - P6-5 (UP) |

Always |

Below 1 Ω |

|

P4-10 (UP) - Body ground |

Always |

10 kΩ or higher |

|

P6-1 (GND) - Body ground |

Always |

Below 1 Ω |

|

P4-2 (E) - Body ground |

Always |

Below 1 Ω |

|

*1 |

Front view of wire harness connector (to Sliding Roof ECU (Sliding Roof Drive Gear Sub-assembly)) |

|

*2 |

Front view of wire harness connector (to Sliding Roof Switch (Roof Console Box Assembly)) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

INSPECT SLIDING ROOF SWITCH (ROOF CONSOLE BOX ASSEMBLY) |

|

(a) Remove the sliding roof switch (roof console box assembly) (See page

|

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

P6-4 (DOWN) - P6-1 (GND) |

TILT DOWN switch is pressed |

Below 1 Ω |

|

P6-4 (DOWN) - P6-1 (GND) |

TILT DOWN switch is not pressed |

10 kΩ or higher |

|

P6-5 (UP) - P6-1 (GND) |

TILT UP switch is pressed |

Below 1 Ω |

|

P6-5 (UP) - P6-1 (GND) |

TILT UP switch is not pressed |

10 kΩ or higher |

|

P6-2 (CLS) - P6-1 (GND) |

SLIDE CLOSE switch is pressed |

Below 1 Ω |

|

P6-2 (CLS) - P6-1 (GND) |

SLIDE CLOSE switch is not pressed |

10 kΩ or higher |

|

P6-3 (OPN) - P6-1 (GND) |

SLIDE OPEN switch is pressed |

Below 1 Ω |

|

P6-3 (OPN) - P6-1 (GND) |

SLIDE OPEN switch is not pressed |

10 kΩ or higher |

|

*1 |

Component without harness connected Sliding Roof Switch (Roof Console Box Assembly) |

| OK | .gif) |

REPLACE SLIDING ROOF ECU (SLIDING ROOF DRIVE GEAR SUB-ASSEMBLY) |

| NG | .gif) |

REPLACE SLIDING ROOF SWITCH (ROOF CONSOLE BOX ASSEMBLY) |

Sensor (Motor) Failure (B2341,B2344)

Sensor (Motor) Failure (B2341,B2344)

DESCRIPTION

When the sliding roof ECU (sliding roof drive gear sub-assembly) detects a motor

malfunction and the sliding roof operation is stopped, DTC B2341 is output.

When the sliding roof ECU ( ...

Window / Glass

Window / Glass

...

Other materials about Toyota Venza:

Crankshaft Position Sensor

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT FENDER APRON SEAL RH

2. REMOVE CRANKSHAFT POSITION SENSOR

(a) Disconnect the sensor connector.

(b) Remove the bolt and sensor.

Inspection

INSPECTION

PROCEDURE ...

Compressor Solenoid Circuit (B1451/51)

DESCRIPTION

In this circuit, the A/C compressor receives a refrigerant compression demand

signal from the A/C amplifier.

Based on this signal, the A/C compressor changes the amount of compressor output.

DTC No.

DTC Detection Conditio ...

System Description

SYSTEM DESCRIPTION

1. ENGINE IMMOBILISER SYSTEM DESCRIPTION

The immobiliser system is a theft deterrent system that determines whether to

disable starting of the SFI system based on a comparison of the key ID code and

the vehicle pre-registered code. The ...

0.1582

.gif)

.png)

.png)