Toyota Venza: Side Turn Signal Light Assembly

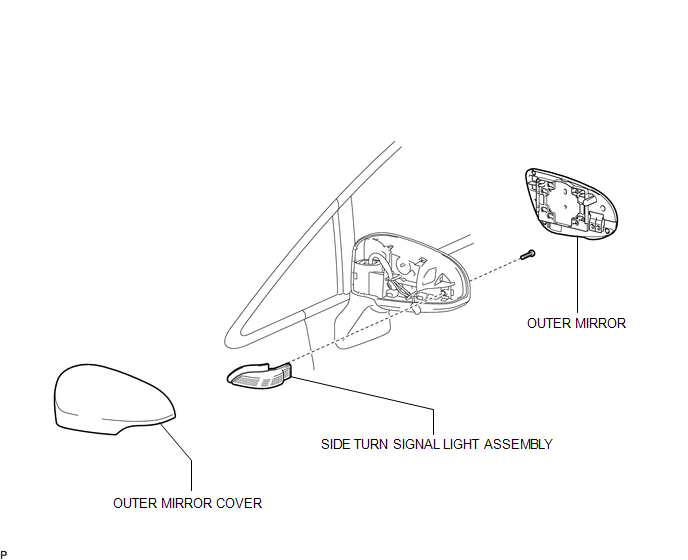

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH and LH sides.

- The procedure described below is for the LH side.

PROCEDURE

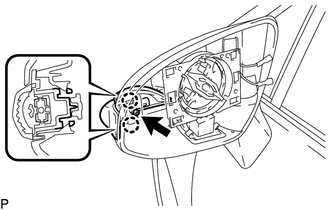

1. REMOVE OUTER MIRROR

.gif)

2. REMOVE OUTER MIRROR COVER

.gif)

3. REMOVE SIDE TURN SIGNAL LIGHT ASSEMBLY

|

(a) Remove the screw. |

|

(b) Disengage the 2 claws.

(c) Disconnect the connector and remove the side turn signal light assembly.

Inspection

INSPECTION

PROCEDURE

1. INSPECT SIDE TURN SIGNAL LIGHT ASSEMBLY LH

|

(a) Connect a positive (+) lead from the battery to terminal 1 and a negative (-) lead to terminal 2. |

|

(b) Check that the side turn signal light comes on.

OK:

The light comes on.

Text in Illustration|

*1 |

Component without harness connected (Side Turn Signal Light Assembly LH) |

If the result is not as specified, replace the side turn signal light assembly LH.

2. INSPECT SIDE TURN SIGNAL LIGHT ASSEMBLY RH

|

(a) Connect a positive (+) lead from the battery to terminal 1 and a negative (-) lead to terminal 2. |

|

(b) Check that the side turn signal light comes on.

OK:

The light comes on.

Text in Illustration|

*1 |

Component without harness connected (Side Turn Signal Light Assembly RH) |

If the result is not as specified, replace the side turn signal light assembly RH.

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH and LH sides.

- The procedure described below is for the LH side.

PROCEDURE

1. INSTALL SIDE TURN SIGNAL LIGHT ASSEMBLY

(a) Connect the connector.

(b) Engage the 2 claws.

(c) Install the side turn signal light assembly with the screw.

2. INSTALL OUTER MIRROR COVER

.gif)

3. INSTALL OUTER MIRROR

.gif)

Relay

Relay

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT TAILLIGHT RELAY (TAIL)

(a) Remove the taillight relay from the main body ECU (driver side junction

block assembly) ...

Stop Light Switch

Stop Light Switch

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE STOP LIGHT SWITCH ASSEMBLY

(a) Disconnect the connector.

...

Other materials about Toyota Venza:

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. SEPARATE FRONT DISC BRAKE CALIPER ASSEMBLY

3. ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Exhaust Side)

(a) Apply a light coat of engine oil to a new O-ring, and install it

to the oil control valve.

Text in Illustration

*1

...

Front Stabilizer Bar(when Not Using The Engine Support Bridge For Awd)

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT STABILIZER LINK ASSEMBLY

(a) Inspect the turning torque of the ball joint.

(1) Secure the front stabilizer link assembly in a vise using aluminum

...

0.1569

.png)