Toyota Venza: Stop Light Switch

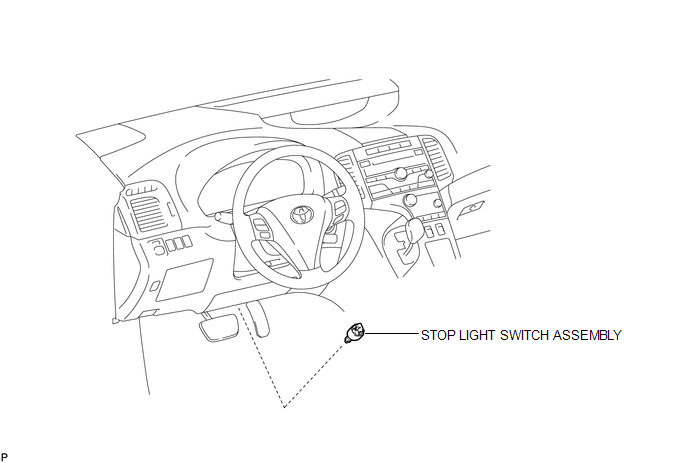

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE STOP LIGHT SWITCH ASSEMBLY

|

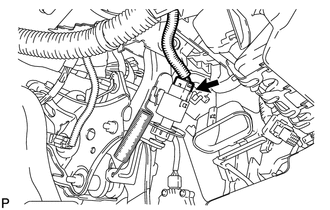

(a) Disconnect the connector. |

|

|

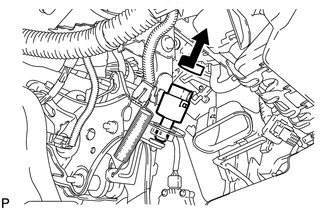

(b) Turn the stop light switch assembly counterclockwise and remove the stop light switch assembly. |

|

Inspection

INSPECTION

PROCEDURE

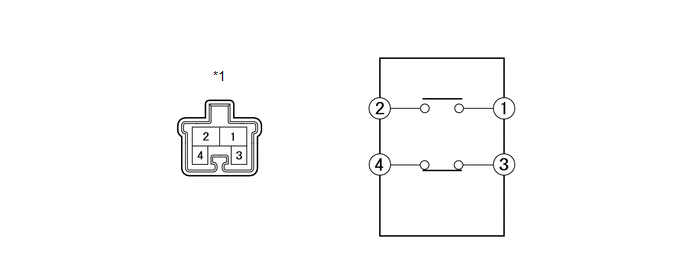

1. INSPECT STOP LIGHT SWITCH ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

Pushed |

10 kΩ or higher |

|

Not pushed |

Below 1 Ω |

|

|

3 - 4 |

Pushed |

Below 1 Ω |

|

Not pushed |

10 kΩ or higher |

|

*1 |

Component without harness connected (Stop Light Switch Assembly) |

If the result is not as specified, replace the stop light switch assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL STOP LIGHT SWITCH ASSEMBLY

|

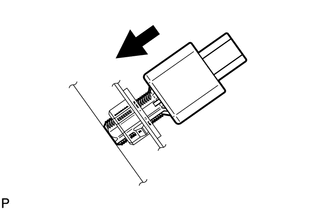

(a) Insert the stop light switch assembly until the rod hits the pedal. NOTICE: When inserting the stop light switch assembly, support the pedal from behind so that the pedal is not depressed. |

|

|

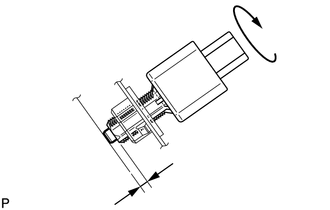

(b) Make a quarter turn clockwise to install the stop light switch assembly. Torque: 1.5 N·m {15 kgf·cm, 13 in·lbf} or less NOTICE: When inserting the stop light switch assembly, support the pedal from behind so that the pedal is not depressed. |

|

(c) Connect the connector.

(d) Check the protrusion of the rod.

Protrusion of the rod:

1.5 to 2.5 mm (0.0591 to 0.0984 in.)

If the protrusion is not as specified, adjust it.

NOTICE:

Do not depress the brake pedal.

Side Turn Signal Light Assembly

Side Turn Signal Light Assembly

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The procedure described below is for the LH si ...

Turn Signal Flasher Assembly

Turn Signal Flasher Assembly

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT TURN SIGNAL FLASHER ASSEMBLY

(a) Disconnect the D34 turn signal flasher assembly connector.

...

Other materials about Toyota Venza:

Power Source Circuit

DESCRIPTION

1. w/o Multi-information Display

(a) This circuit is the power source circuit for the accessory meter assembly.

This circuit provides two types of power sources; one is a constant power source

mainly used as a backup power source, and the oth ...

Washer fluid

If any washer does not work or the low windshield washer fluid level warning

light comes on, the washer tank may be empty. Add washer fluid.

CAUTION

- When refilling the washer fluid

Do not refill the washer fluid when the engine is hot or running ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

Use the table below to help determine the cause of problem symptoms. If multiple

suspected areas are listed, the potential causes of the symptoms are listed in order

of probability in the "Suspected Area" column of the tab ...

0.1522