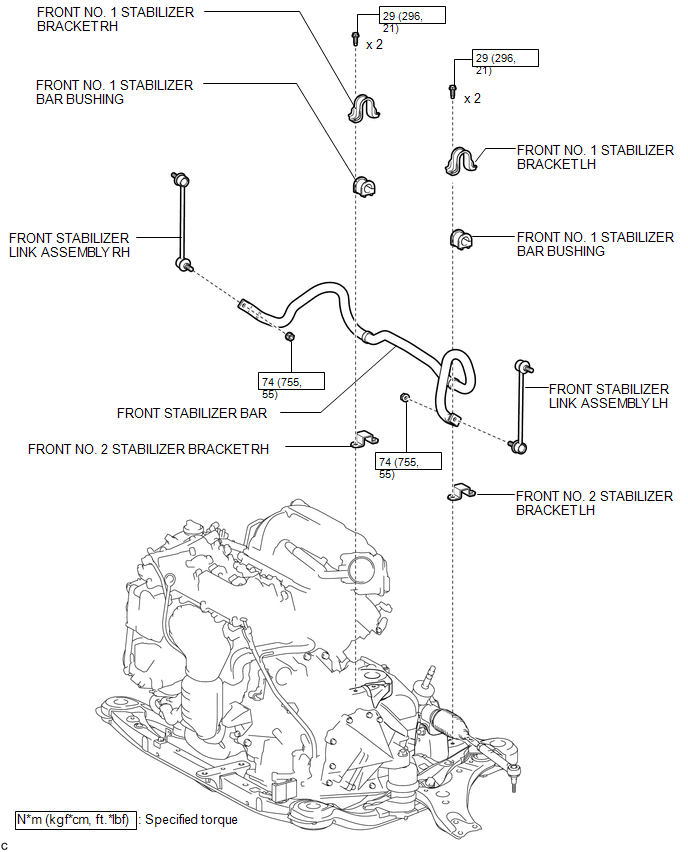

Toyota Venza: Front Stabilizer Bar(when Not Using The Engine Support Bridge For Awd)

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

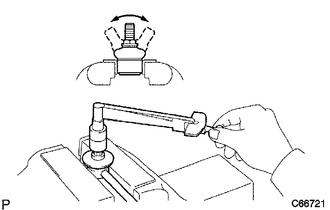

1. INSPECT FRONT STABILIZER LINK ASSEMBLY

|

(a) Inspect the turning torque of the ball joint. (1) Secure the front stabilizer link assembly in a vise using aluminum plates. (2) Install the nut to the front stabilizer link assembly stud. (3) Using a torque wrench, turn the nut continuously at a rate of 3 to 5 seconds per turn and take the torque reading on the 5th turn. Turning torque: 0.05 to 1.96 N*m (0.5 to 20 kgf*cm, 0.4 to 17 in.*lbf) If the turning torque is not within the specified range, replace the front stabilizer link assembly with a new one. |

|

(b) Inspect the dust cover.

(1) Check that the dust cover is not cracked and that there is no grease on it.

Removal

REMOVAL

PROCEDURE

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

for 1AR-FE: (See page .gif) )

)

for 2GR-FE: (See page .gif) )

)

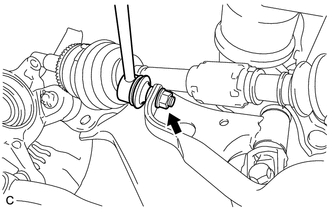

2. SEPARATE FRONT STABILIZER LINK ASSEMBLY LH

|

(a) Remove the nut and separate the front stabilizer link assembly LH. HINT: If the ball joint turns together with the nut, use a hexagon wrench (6 mm) to hold the stud bolt. |

|

3. SEPARATE FRONT STABILIZER LINK ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

4. REMOVE FRONT NO. 1 STABILIZER BRACKET LH

|

(a) Remove the 2 bolts and front No. 1 stabilizer bracket LH from the front frame assembly. |

|

5. REMOVE FRONT NO. 1 STABILIZER BRACKET RH

HINT:

Perform the same procedure as for the LH side.

6. REMOVE FRONT STABILIZER BAR

7. REMOVE FRONT NO. 2 STABILIZER BRACKET LH

|

(a) Remove the front No. 2 stabilizer bracket LH from the front stabilizer bar bushing. |

|

8. REMOVE FRONT NO. 2 STABILIZER BRACKET RH

HINT:

Perform the same procedure as for the LH side.

9. REMOVE FRONT NO. 1 STABILIZER BAR BUSHING

(a) Remove the 2 front No. 1 stabilizer bar bushings from the front stabilizer bar.

Installation

INSTALLATION

PROCEDURE

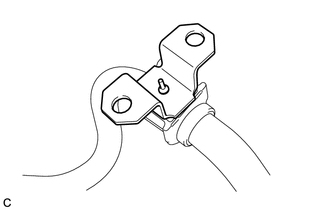

1. INSTALL FRONT NO. 1 STABILIZER BAR BUSHING

|

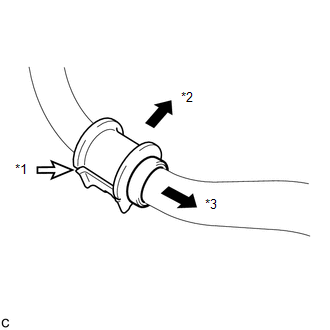

(a) Install the 2 front No. 1 stabilizer bar bushings to the front stabilizer bar as shown in the illustration. Text in Illustration

NOTICE: When installing the front No. 1 stabilizer bar bushings, make sure that the cutout faces the rear of the vehicle. |

|

2. INSTALL FRONT NO. 2 STABILIZER BRACKET LH

|

(a) Install the front No. 2 stabilizer bracket LH to the front No. 1 stabilizer bar bushing. |

|

3. INSTALL FRONT NO. 2 STABILIZER BRACKET RH

HINT:

Perform the same procedure as for the LH side.

4. INSTALL FRONT STABILIZER BAR

(a) Install the front stabilizer bar to the front frame assembly.

5. INSTALL FRONT NO. 1 STABILIZER BRACKET LH

|

(a) Install the front No. 1 stabilizer bracket LH to the front frame assembly with the 2 bolts. Torque: 29 N·m {296 kgf·cm, 21 ft·lbf} |

|

6. INSTALL FRONT NO. 1 STABILIZER BRACKET RH

HINT:

Perform the same procedure as for the LH side.

7. INSTALL FRONT STABILIZER LINK ASSEMBLY LH

|

(a) Install the front stabilizer link assembly LH with the nut. Torque: 74 N·m {755 kgf·cm, 55 ft·lbf} HINT: If the ball joint turns together with the nut, use a hexagon wrench (6 mm) to hold the stud bolt. |

|

8. INSTALL FRONT STABILIZER LINK ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

9. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

for 1AR-FE: (See page .gif) )

)

for 2GR-FE: (See page .gif) )

)

Installation

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the LH side and RH side.

The following procedure listed below is for the LH side.

PROCEDURE

1. SECURE FRONT ...

Other materials about Toyota Venza:

Selecting trailer ball

Use the correct trailer ball for your application.

1. Trailer ball load rating

Matches or exceeds the gross trailer weight rating of the trailer.

2. Ball diameter

Matches the size of the trailer coupler. Most couplers are stamped with the required

trai ...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE MAGNETIC SWITCH ASSEMBLY

(a) Remove the nut and disconnect the lead wire from the magnetic switch.

(b) Remove the 2 screws holding the magnetic switch to t ...

Customize Parameters

CUSTOMIZE PARAMETERS

PROCEDURE

1. CUSTOMIZE INTUITIVE PARKING ASSIST SYSTEM

(a) Customizing with the Techstream

NOTICE:

When the customer requests a change in a function, first make sure that

the function can be customized.

Be sure to make ...

0.1145

.png)

.png)

.png)

.png)