Toyota Venza: Room Light

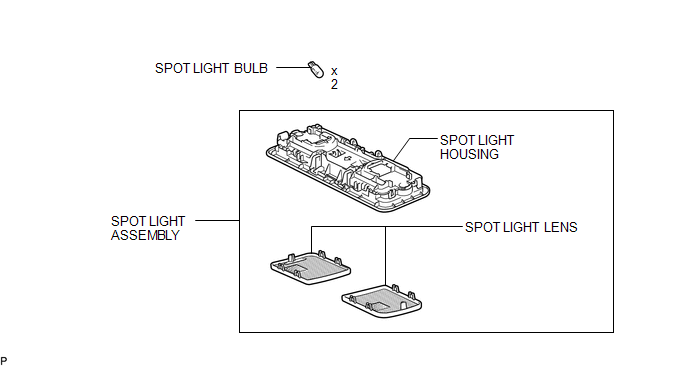

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE SPOT LIGHT ASSEMBLY

|

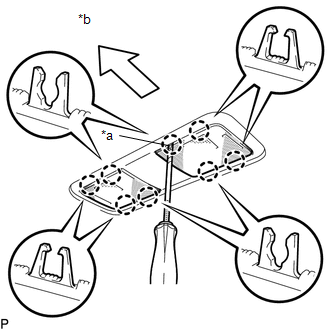

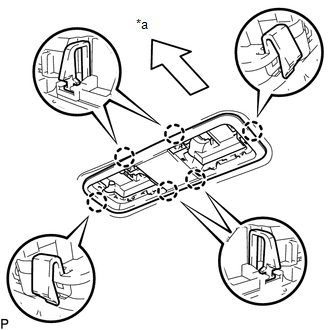

(a) Using a screwdriver with its tip wrapped with protective tape, disengage the 8 claws to remove the 2 spot light lenses. Text in Illustration

|

|

|

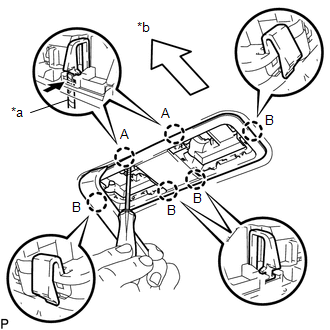

(b) Using a screwdriver with its tip wrapped with protective tape and moulding remover, disengage the 2 claws (A). Text in Illustration

|

|

(c) Disengage the 4 claws (B) and disconnect the spot light housing.

|

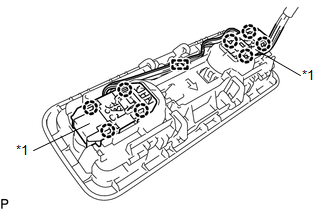

(d) Using a screwdriver, disengage the 8 claws and clamp to remove the spot light housing from the 2 map light sub-assemblies. Text in Illustration

|

|

2. REMOVE SPOT LIGHT BULB

(a) Remove the 2 spot light bulbs from the 2 map light sub-assemblies.

Installation

INSTALLATION

PROCEDURE

1. INSTALL SPOT LIGHT BULB

(a) Install the 2 spot light bulbs to the 2 map light sub-assemblies.

2. INSTALL SPOT LIGHT ASSEMBLY

|

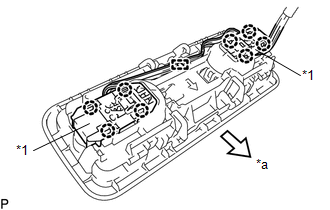

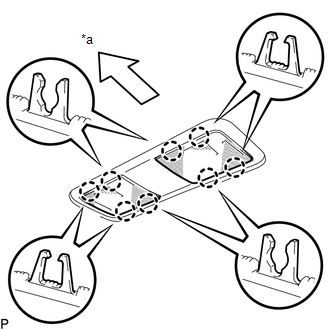

(a) Engage the 8 claws and clamp to connect the spot light housing to the 2 map light sub-assemblies as shown in the illustration. Text in Illustration

|

|

|

(b) Engage the 6 claws to install the spot light housing. Text in Illustration

|

|

|

(c) Engage the 8 claws to install the 2 spot light lenses. Text in Illustration

|

|

Relay

Relay

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT DOME CUT RELAY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

...

Vanity Light

Vanity Light

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL VANITY LIGHT ASSEMBLY

(a) Engage the 3 claws and install the vanity light assembly.

...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL MANUAL VALVE

(a) Coat the manual valve with ATF and install it to the transmission valve body

assembly.

2. SUPPORT ENGINE ASSEMBLY

3. INSTALL TRANSMISSION VALVE BODY ASSEMBLY

(a) Coat the O-ring of the transmission ...

Skid Control ECU Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

Skid Control ECU Communication Stop Mode

"ABS/VSC/TRAC" is not displayed on "CAN Bus Check" screen of

the Techstr ...

Fuel Tank Cap

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL TANK CAP ASSEMBLY

(a) Visually check that the fuel tank cap assembly and gasket are not

deformed or damaged.

Text in Illustration

*a

Gasket

...

0.1582