Toyota Venza: Inspection

INSPECTION

PROCEDURE

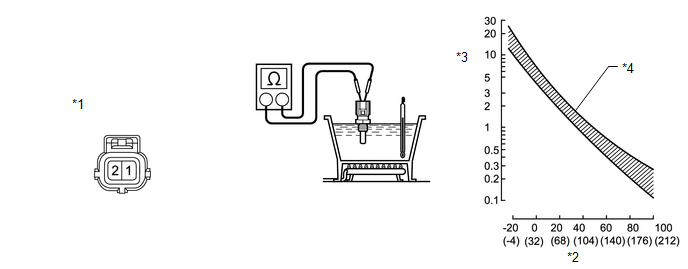

1. INSPECT ENGINE COOLANT TEMPERATURE SENSOR

Text in Illustration

Text in Illustration

|

*1 |

Component without harness connected (Engine Coolant Temperature Sensor) |

*2 |

Temperature °C (°F) |

|

*3 |

Resistance Ω |

*4 |

Acceptable |

(a) Partially immerse the sensor in water and warm up the water.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

20°C (68°F) |

2.32 to 2.59 kΩ |

|

1 - 2 |

80°C (176°F) |

0.310 to 0.326 kΩ |

NOTICE:

When checking the sensor in water, keep the terminals dry. After the check, wipe the sensor dry.

If the result is not as specified, replace the engine coolant temperature sensor.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE UNDER COVER

2. REMOVE NO. 2 ENGINE UNDER COVER

3. REMOVE WINDSHIELD WIPER MOTOR AND LINK

(a) Remove the windshield wiper motor and link (See page

).

4. ...

Other materials about Toyota Venza:

System Description

SYSTEM DESCRIPTION

1. ENGINE IMMOBILISER SYSTEM DESCRIPTION

The engine immobiliser system is designed to prevent the vehicle from being stolen.

This system uses the transponder key ECU assembly that stores the key codes of authorized

ignition keys. If an ...

Checking Monitor Status

CHECKING MONITOR STATUS

The purpose of the monitor result (mode 06) is to allow access to the results

of on-board diagnostic monitoring tests of specific components/systems that are

not continuously monitored. Examples are catalysts and evaporative emissi ...

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

0.1738