Toyota Venza: Replacement

REPLACEMENT

PROCEDURE

1. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

(a) Start up the engine.

(b) Turn the A/C switch on.

(c) Operate the cooler compressor at an engine speed of approximately 1000 rpm for 5 to 6 minutes to circulate the refrigerant. This causes most of the compressor oil from the various components of the A/C system to collect in the A/C compressor.

(d) Stop the engine.

(e) Recover the refrigerant from the A/C system using a refrigerant recovery unit.

2. CHARGE WITH REFRIGERANT

(a) Perform vacuum purging using a vacuum pump.

(b) Charge with refrigerant HFC-134a (R134a).

Standard:

450 to 550 g (15.9 to 19.4 oz.)

SST: 09985-20010

09985-02010

09985-02050

09985-02060

09985-02070

09985-02080

09985-02090

09985-02110

09985-02130

09985-02140

09985-02150

NOTICE:

Do not turn the A/C switch on before charging with refrigerant. Doing so will cause the compressor to work without refrigerant, resulting in overheating of the compressor.

HINT:

Ensure that sufficient refrigerant is available to recharge the system when using a refrigerant recovery unit. Refrigerant recovery units are not always able to recover 100% of the refrigerant from an A/C system.

3. WARM UP ENGINE

(a) Keep the A/C switch on for at least 2 minutes to warm up the compressor.

NOTICE:

Be sure to warm up the compressor when turning the A/C switch on after removing and installing the cooler refrigerant lines (including the compressor), to prevent damage to the compressor.

4. INSPECT FOR REFRIGERANT LEAK

(a) After recharging with refrigerant, inspect for refrigerant leaks using a halogen leak detector.

(b) Carry out the test under the following conditions:

- Turn the ignition switch off.

- Secure good ventilation (the halogen leak detector may react to volatile gases which are not refrigerant, such as evaporated gasoline and exhaust gas).

- Repeat the test 2 or 3 times.

- Make sure that there is some refrigerant remaining in the refrigeration

system.

When the compressor is off: approx. 392 to 588 kPa (4.0 to 6.0 kgf/cm2, 57 to 85 psi)

|

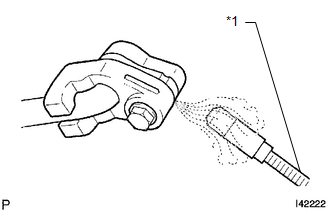

(c) Using a halogen leak detector, inspect for refrigerant leaks from the refrigerant lines. Text in Illustration

|

|

|

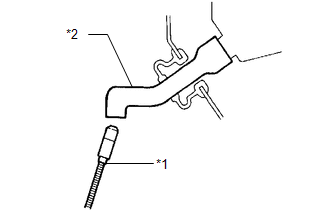

(d) Bring the halogen leak detector close to the drain hose with the detector's power off, and then turn the detector on. Text in Illustration

HINT:

|

|

(e) If a refrigerant leak is not detected from the drain hose, remove the blower motor control from the cooling unit. Insert the halogen leak detector sensor into the unit and perform the test.

(f) Disconnect the pressure switch connector and leave it for approximately 20 minutes. Bring the halogen leak detector close to the pressure switch and perform the test.

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT REFRIGERANT PRESSURE WITH MANIFOLD GAUGE SET

HINT:

This is a method where a manifold gauge set is used to help locate the problem.

(a) Read the manifold ...

Refrigerant Line

Refrigerant Line

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Other materials about Toyota Venza:

Back Door Entry Lock and Unlock Functions do not Operate

DESCRIPTION

When the back door entry lock and unlock functions do not operate, one of the

following may be malfunctioning: 1) power door lock control system; 2) outside electrical

key oscillator (for rear side); 3) certification ECU (smart key ECU assembl ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

Adjustment

ADJUSTMENT

PROCEDURE

1. ADJUST STEERING WHEEL OFF CENTER

(a) Inspect steering wheel off center.

(1) Apply masking tape on the top center of the steering wheel and steering

column upper cover.

Text in Illustration

*1

...

0.1513